Lithium secondary battery

A lithium secondary battery and lithium ion technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as loss of initial battery capacity, improve charge-discharge cycle characteristics, suppress capacity reduction, and increase discharge termination potential Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0071] Hereinafter, a lithium secondary battery according to a first embodiment of the present invention will be described.

[0072] The lithium secondary battery of this embodiment includes: a positive electrode containing a positive electrode active material; a negative electrode containing a negative electrode active material capable of storing and releasing lithium; a separator arranged between the positive electrode and the negative electrode; and a nonaqueous electrolyte.

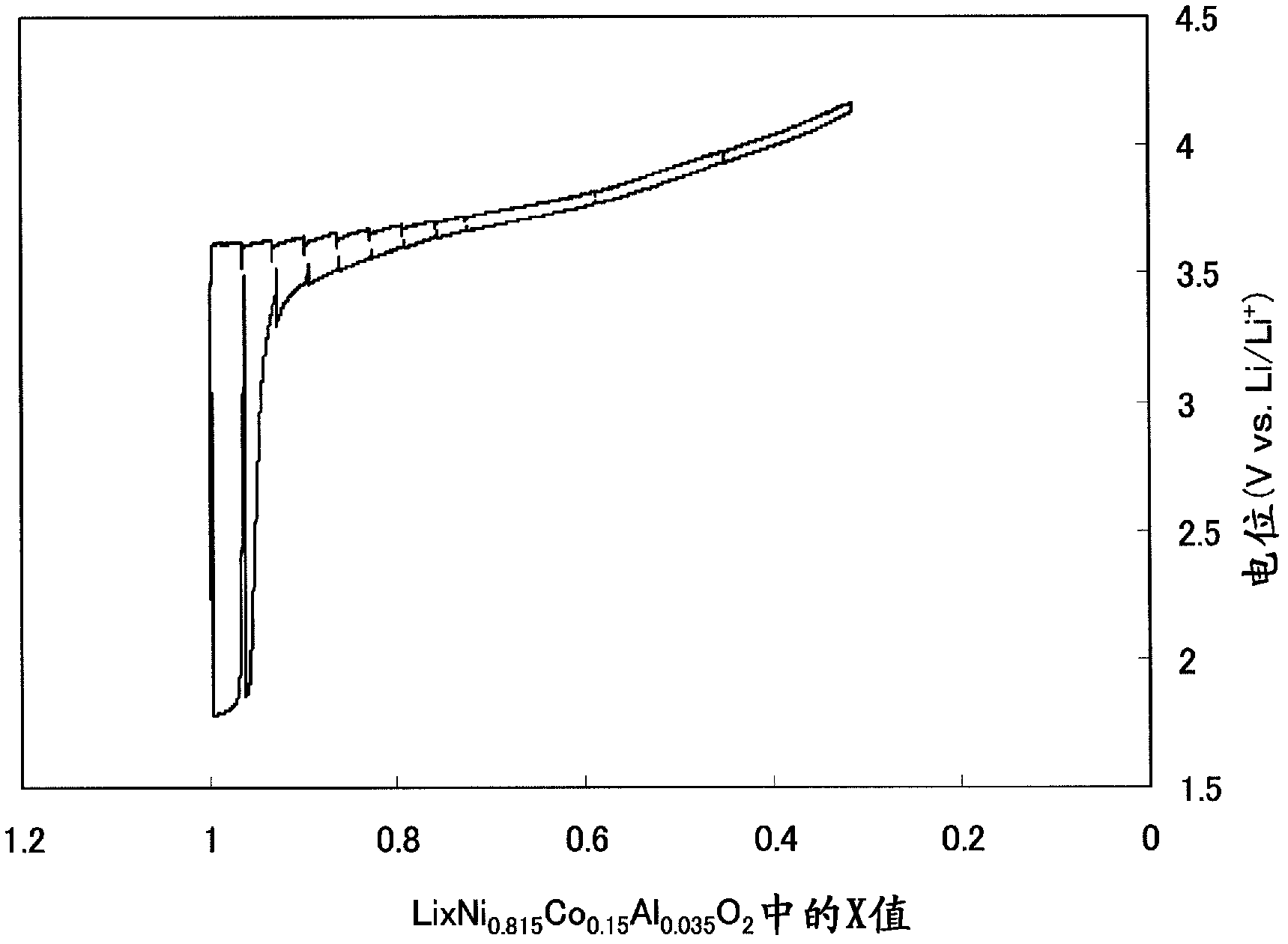

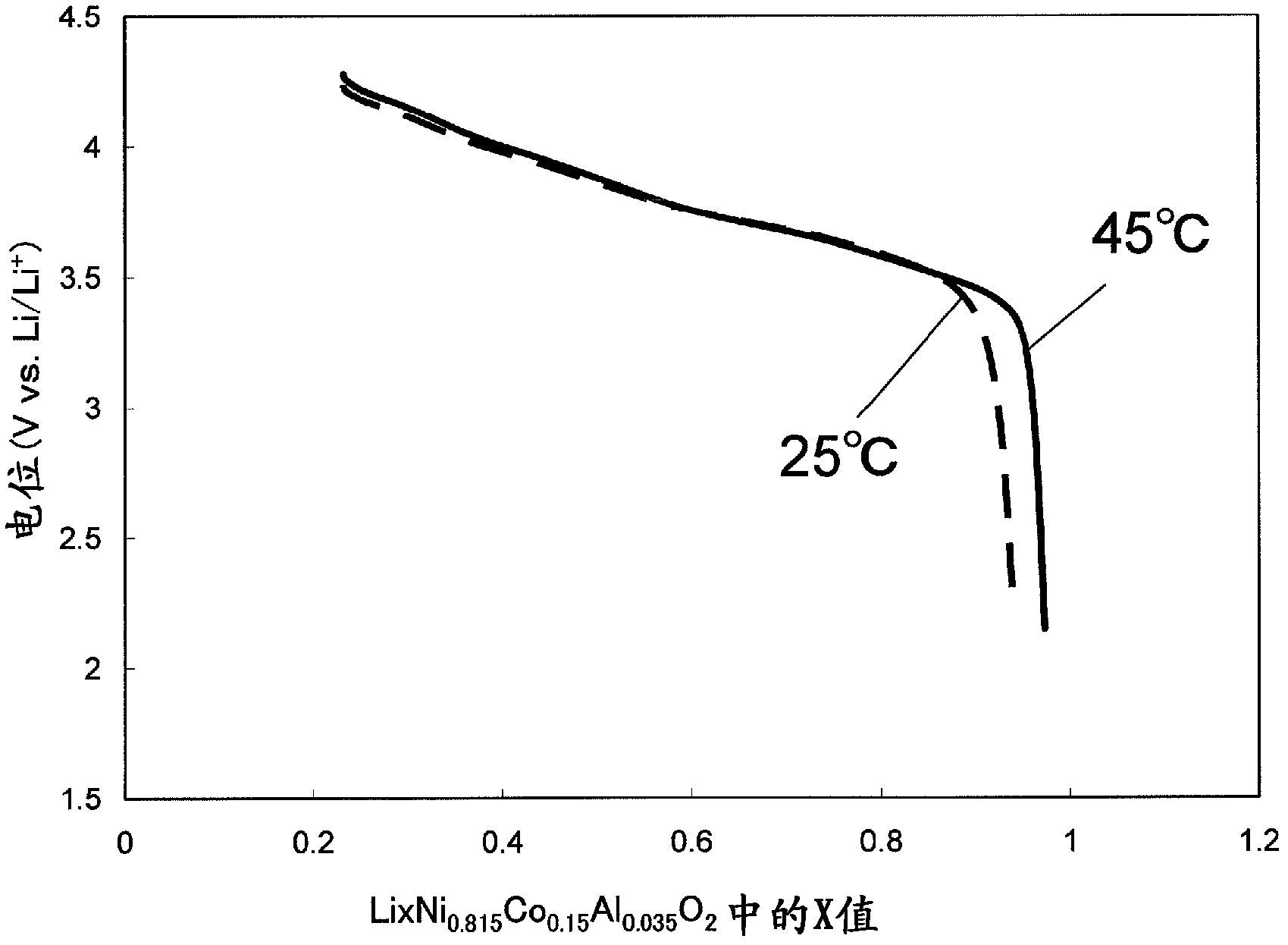

[0073] The positive electrode active material in this embodiment is a nickel-based lithium-containing composite oxide capable of occluding and releasing lithium. Examples of nickel-based lithium-containing composite oxides include LiNiO 2 As a basis, a part of Ni is replaced with another element selected from Mg, Sc, Y, Mn, Fe, Co, Ni, Cu, Zn, Al, Cr, Pb, Sb, and B.

[0074] As the negative electrode active material in this embodiment, a graphite-based material having a reversible capacity of 350 mAh...

Embodiment 1~4 and comparative example 1~3

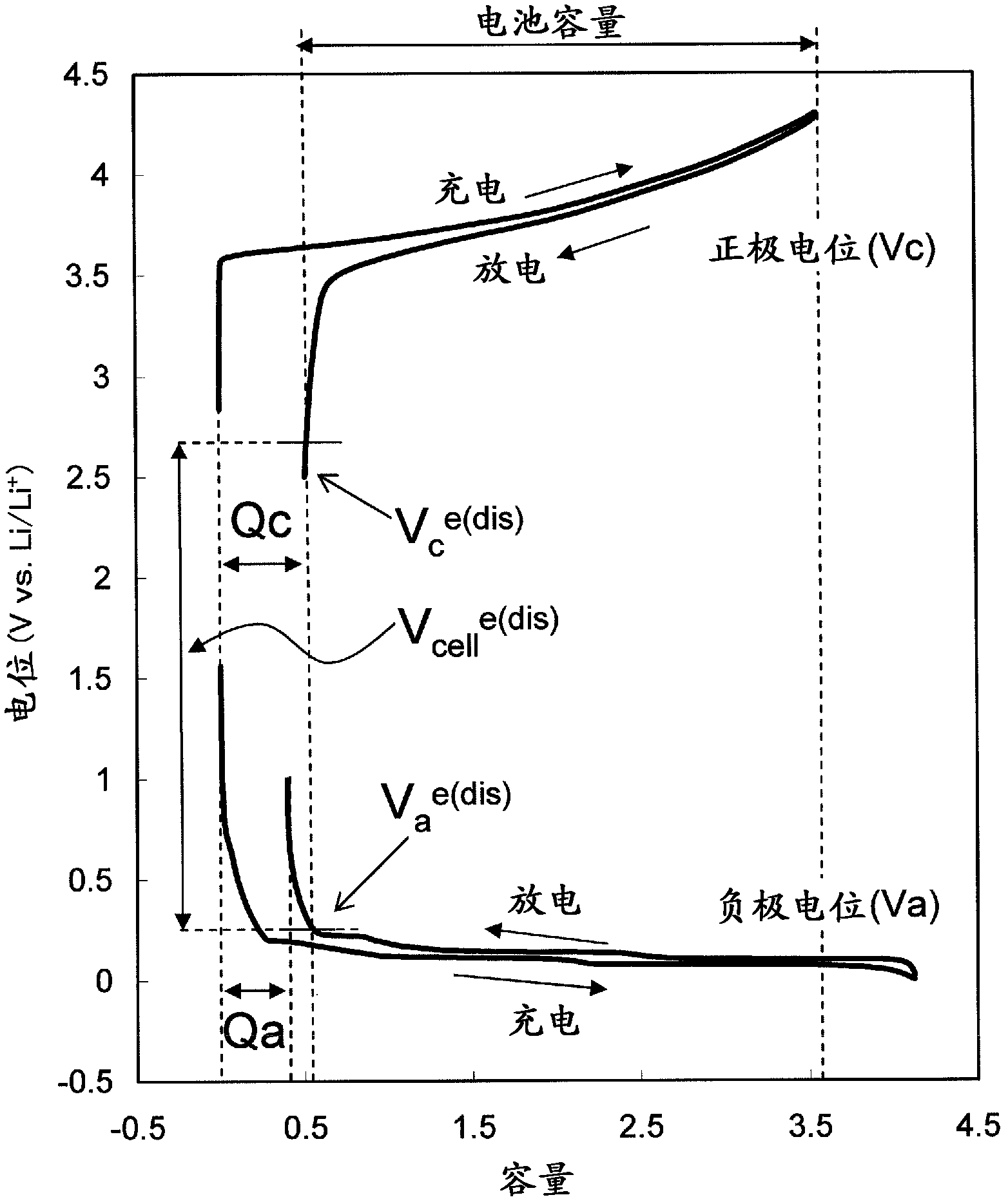

[0246] Cells D to F for evaluation with different irreversible capacity ratios Qc / Qa of the positive and negative electrodes were produced, and the relationship between the irreversible capacity ratio Qc / Qa, the discharge termination potential of the positive electrode, and the charge-discharge cycle characteristics was examined.

[0247] (3-1) Preparation of unit cell D for evaluation

[0248] (3-1-1) Preparation of positive electrode

[0249] Using the same method as that described in (1-1) of (Experiment 1), a 0.815 co 0.15 Al 0.035 o 2 Indicates the composition of the positive active material.

[0250] To get LiNi 0.815 co 0.15 Al 0.035 o 2 100 g of powder was sufficiently mixed with 2 g of acetylene black (conductive agent), 1.25 g of artificial graphite (conductive agent), 1.25 g of polyvinylidene fluoride powder (binder) and 50 ml of organic solvent (NMP) to prepare a mixture paste. This mixture paste was coated on one side of an aluminum foil (positive electrode...

Embodiment 5~7

[0289] Using a negative electrode active material containing a graphite-based material and lithium titanium oxide (LTO), evaluation unit cells H to J having different weight ratios of LTO and graphite-based material were produced. Using these unit cells for evaluation, the relationship between the weight ratio of LTO and the graphite-based material, the irreversible capacity ratio of the positive electrode and the negative electrode, and the charge-discharge cycle characteristics was examined.

[0290] (4-1) Production of cells H to J for evaluation

[0291] (4-1-1) Preparation of positive electrode

[0292] Using the same method as that described in (2-1) of (Experiment 2), a 0.815 co 0.15 Al 0.035 o 2 Indicates the composition of the positive active material.

[0293] (4-1-2) Preparation of negative electrode

[0294] A negative electrode was produced by mixing lithium titanate (LTO) into a graphite material and coating it on a negative electrode current collector.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com