Method for preparing modified microwave activated carbon sorbent

A technology of activated carbon adsorption and activated carbon, which is applied in the field of preparation of modified activated carbon adsorbent and modified microwave activated carbon adsorbent, to achieve the effect of easy acquisition, low cost and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: A kind of preparation method of modified microwave activated carbon adsorbent, concrete operation is as follows:

[0018] (1) Grind and sieve microwave coconut shell activated carbon to 40 mesh, take 17g of activated carbon and wash with distilled water for 3 times, dry at 100°C for 24 hours, then cool down to room temperature naturally in a drying dish;

[0019] (2) Place the treated activated carbon in 34ml of 0.5mol / L potassium carbonate solution, impregnate it for 4h at 30°C, with an ultrasonic frequency of 28KHz, and then dry it in a constant temperature drying oven at 100°C for 24h;

[0020] (3) Finally, place the activated carbon in a muffle furnace and roast it at 350°C for 4 hours, then cool it down to room temperature naturally in a drying dish to obtain the modified microwave activated carbon adsorbent.

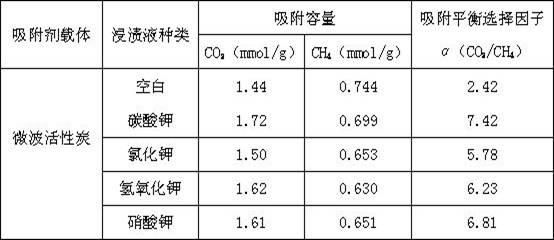

[0021] (4) Take 2.0 g of modified microwave activated carbon adsorbent, and absorb and separate CO at 25 °C 2 and CH 4 gas, CO 2 and CH 4 Th...

Embodiment 2

[0022] Example 2: A kind of preparation method of modified microwave activated carbon adsorbent, concrete operation is as follows:

[0023] (1) Grind and sieve the microwave coal-based activated carbon to 50 mesh, take 17g of activated carbon and wash it with distilled water for 4 times, dry it at 110°C for 18 hours, and then naturally cool it down to room temperature in a drying dish;

[0024] (2) Place the treated activated carbon in 51ml of 1mol / L potassium chloride solution, impregnate it for 2h at 40°C, with an ultrasonic frequency of 35KHz, and then dry it in a constant temperature drying oven at 110°C for 18h;

[0025] (3) Finally, place the activated carbon in a muffle furnace and roast it at 200°C for 5 hours, then cool it down to room temperature naturally in a drying dish to obtain the modified microwave activated carbon adsorbent.

[0026] (4) Take 2.0 g of modified microwave activated carbon adsorbent, and absorb and separate CO at 25 °C 2 and CH 4 gas, CO 2 ...

Embodiment 3

[0027] Example 3: A kind of preparation method of modified microwave activated carbon adsorbent, concrete operation is as follows:

[0028] (1) Grind and sieve microwave coconut shell activated carbon to 60 mesh, take 17g of activated carbon and wash with distilled water for 3 times, dry at 120°C for 12 hours, then cool down to room temperature naturally in a drying dish;

[0029] (2) Place the treated activated carbon in 68ml of 2mol / L potassium hydroxide solution, impregnate it for 0.5h at 35°C and ultrasonic frequency of 45KHz, and then dry it in a constant temperature drying oven at 120°C for 12h;

[0030] (3) Finally, place the activated carbon in a muffle furnace and roast it at 650°C for 2 hours, then cool it down to room temperature naturally in a drying dish to obtain the modified microwave activated carbon adsorbent.

[0031] (4) Take 2.0 g of modified microwave activated carbon adsorbent, and absorb and separate CO at 25 °C2 and CH 4 gas, CO 2 and CH 4 The volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com