Composite frame pipe of bicycle

A technology for composite materials and bicycles, which is applied in the direction of bicycle frames, bicycle accessories, synthetic resin layered products, etc. It can solve the problems affecting the overall mechanical properties of the frame, low surface hardness of composite materials, and affecting appearance, so as to ensure the reliability of use and comfort, low density and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

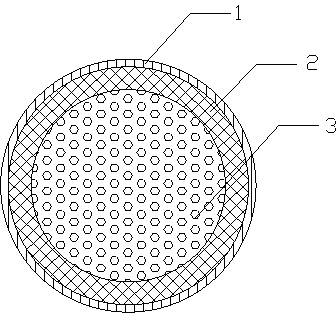

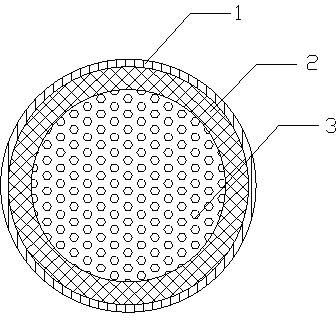

[0023] The composite material base pipe is made by pultrusion, winding, hot pressing and other forming processes, and a layer of metal layer is formed on the surface of the base pipe by melt spraying, electroplating, electroforming or other processes. An appropriate amount of raw materials required for foam foaming is filled into the base pipe and foamed to fill the cavity of the base pipe with foam, thereby obtaining a sandwich structure bicycle frame pipe.

Embodiment 2

[0025] Spray a layer of metal layer on the surface of the forming mold, lay fiber fabric on the metal layer and paint resin glue, or lay prepreg directly, after laying, the mold is closed and pressurized, and the mold is demoulded after the resin is cured. An appropriate amount of raw materials required for foam foaming is filled into the base pipe and foamed to fill the cavity of the base pipe with foam, thereby obtaining a sandwich structure bicycle frame pipe.

Embodiment 3

[0027] The composite material base pipe is made by pultrusion, winding, hot pressing and other forming processes, and a layer of metal layer is formed on the surface of the base pipe by melt spraying, electroplating, electroforming or other processes. Select a suitable foam material and process it into a rod shape with a diameter slightly smaller than the inner diameter of the base pipe. Apply adhesive on the surface of the foam material, insert it into the base pipe, and make it bond with the base pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com