Heat insulation structure of solar thermal power generation high-temperature molten salt storage tank and preparation method for heat insulation structure

A technology for high-temperature molten salt storage tanks and solar thermal power generation, which is applied in thermal insulation, thermal insulation containers, heat exchange equipment, etc., can solve the problems of accelerated thermal convection, reduced energy utilization rate of solar thermal power generation energy storage system, and increased heat loss, etc. Achieve the effect of prolonging service life, excellent reflection and reducing heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

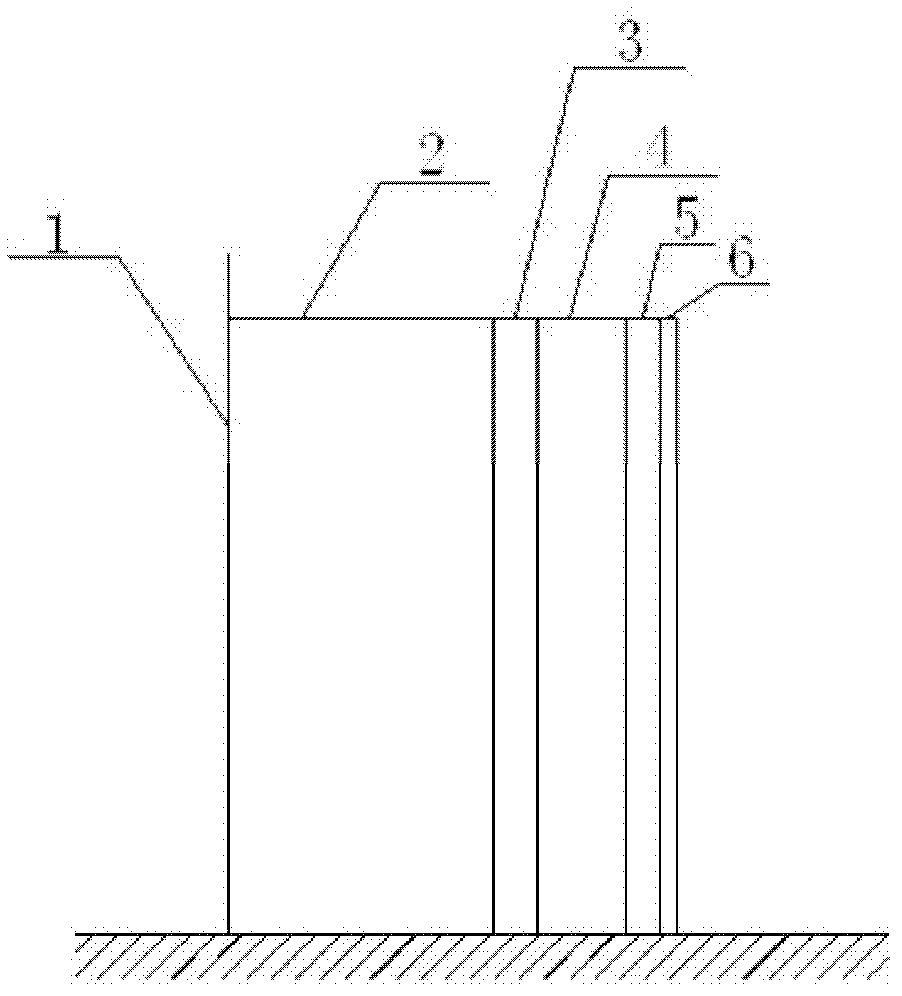

[0025] Such as figure 1 As shown, the heat insulation layer 2 is made of aluminum silicate fiber blanket with a thickness of 5 cm, which is constructed by bundling method on the storage tank 1, and the bundling distance is 20 cm. A 10mm circumferential expansion joint is left in the heat insulation layer 2 structure, which is filled and smoothed with aluminum silicate fiber. The heat insulation layer 2 is laid layer by layer, with staggered seams in the same layer, and the inner and outer layers are laid by pressing seams, bundled layer by layer, and the surface of each layer is leveled and seamed.

[0026] The reflective layer 3 is made of smooth aluminum foil with a thickness of 0.05 mm, which is evenly and evenly pasted on the surface of the heat insulating layer 2 by using a high-temperature adhesive.

[0027] 100mm away from the outer side of the reflective layer 3, with the center of the storage tank as the center, set 40×40×3mm angle steel evenly and vertically at 30°,...

Embodiment 2

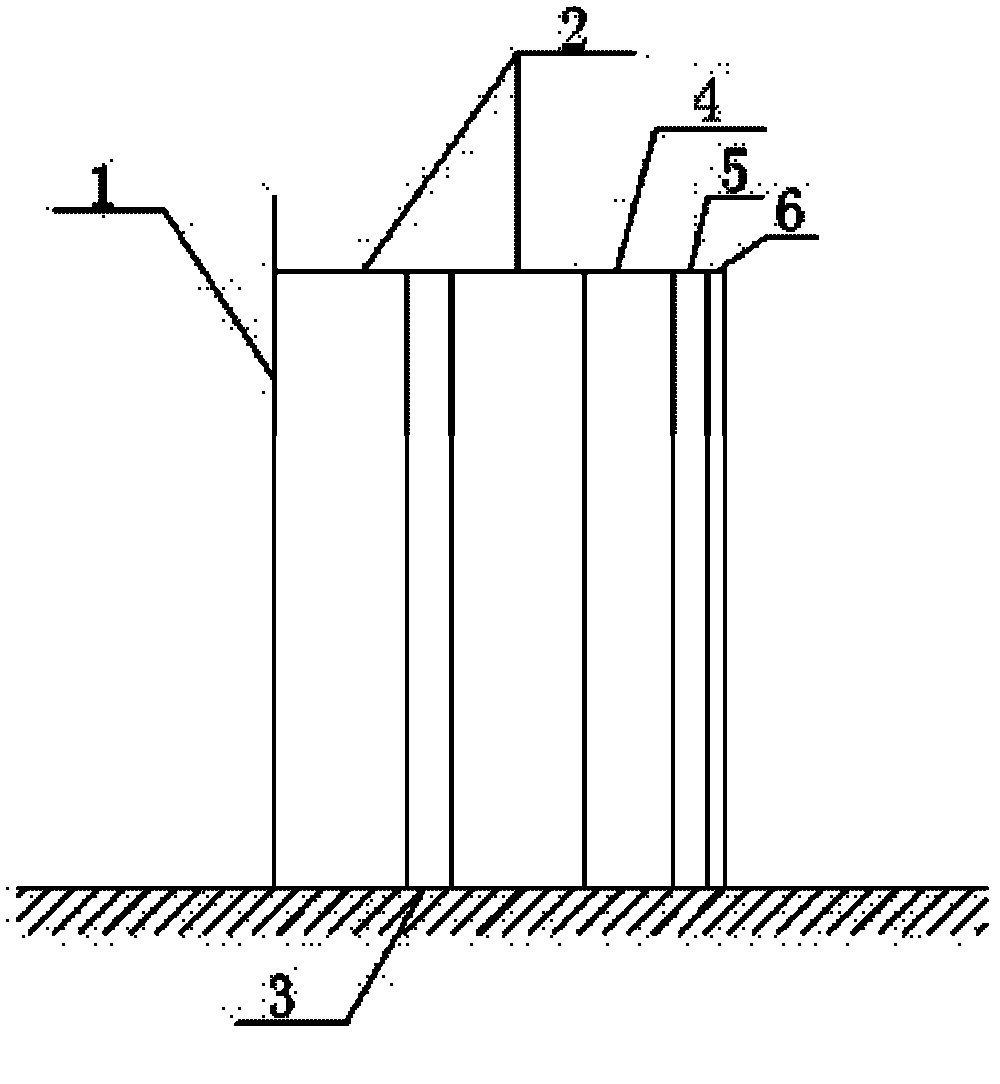

[0030] Such as figure 2 As shown, the material of the thermal insulation layer 2 is silica airgel with a thickness of 1 cm, which is constructed by bundling method, and the bundling distance is 20 cm. There is a 10mm circumferential expansion joint in the heat insulation layer structure, which is filled and smoothed with airgel fibers. The heat insulation layer is laid layer by layer, with staggered seams in the same layer, and the inner and outer layers are laid by pressing seams, bundled layer by layer, and the surface of each layer is leveled and seamed.

[0031] The reflective layer 3 is made of 0.05mm thick smooth stainless steel foil, which is pasted on the surface of the airgel evenly and evenly in advance with a high-temperature adhesive, and placed in the middle of the heat insulating layer.

[0032] 100mm away from the outer side of the insulation layer, with the center of the storage tank as the center, set 40×40×3mm angle steel evenly and vertically at 45°, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com