Purification method of microcrystal graphite

A purification method and technology of microcrystalline graphite, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of high-purity graphite scourge, poisonous gas, and difficult wastewater treatment, so as to reduce the cost of purification and improve environmental protection safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

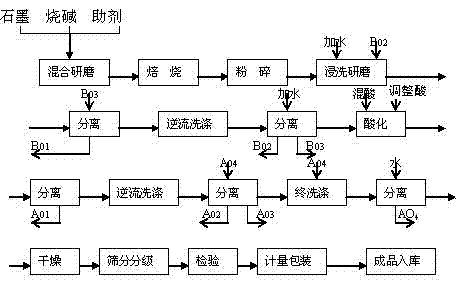

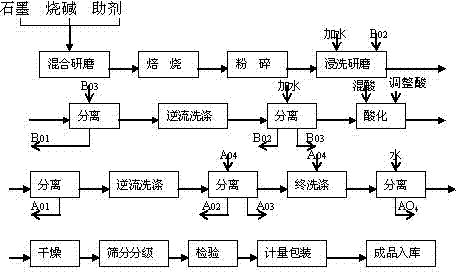

[0025] refer to figure 1 , describe the flow process of the present invention in detail:

[0026] (1) Desiliconization process: Mix and grind microcrystalline graphite with a fixed carbon content of 80-85%, caustic soda and pull-off powder at a weight ratio of 100:5-8:0.1, then roast at 400-450°C, then pulverize and add The alkali-melted material 2-2.5 weight of water is ground into a fine slurry, and then separated to obtain a high-concentration lye B01 containing silicate impurities. The separated graphite is then washed in countercurrent to obtain alkali-melted graphite. Dilute lye B02 (in the upper layer of the container) and waste lye B03 containing silicate impurities (in the lower layer of the container) are obtained by separation.

[0027] (2) Acidification and impurity removal process: mix alkali-melted graphite (dried) and mixed acid at a weight ratio of 1:0.8-0.9, acidify at 70-80°C for 10 minutes, wherein the mixed acid is composed of hydrochloric acid, phosphoric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com