Lightweight porous heat insulation material and preparation method thereof

A thermal insulation and lightweight technology, applied in the field of lightweight porous thermal insulation materials, lightweight porous thermal insulation materials and their preparation, can solve the problems of environmental pollution, land occupation, etc., and achieve good thermal shock performance , easy construction, small volume density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

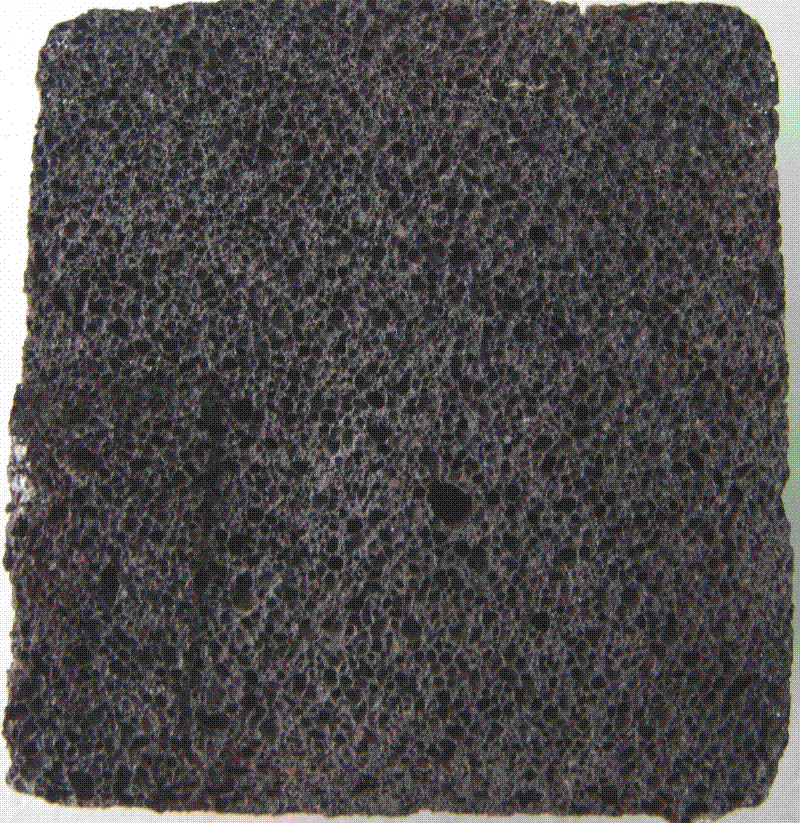

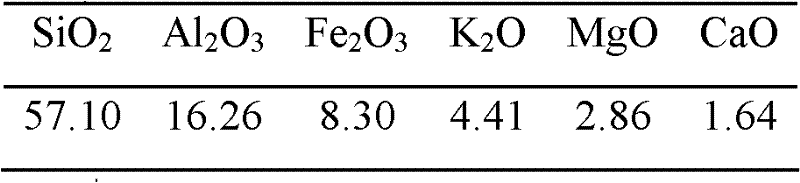

Embodiment 1

[0021] Mix solid wastes such as iron tailings, shale, feldspar, mica, and foaming agent according to the mass ratio of 1:1.3:0.4:0.2:0.03 and stir evenly, add 14% water of the total mass of raw materials to granulate, and age Put it into a SiC refractory mold after obtaining suitable plasticity, and burn it at 1100°C for about 2 hours to obtain a thermal conductivity of 0.127W / m·K, a compressive strength of 9.6MPa, and a density of 1023g / cm3 , the rest of the indicators also meet the requirements of GB13544-2000 and GB6566-2001 lightweight porous thermal insulation materials. Among them, the particle size of the foaming agent is less than 0.075mm, and the particle size of the remaining solid raw materials is less than 0.15mm; the solid waste is composed of iron tailings, coal gangue and old bricks and tiles according to the mass ratio of 25:3:2; the temperature system For: below 400°C, the heating rate is 5°C / min; from 400°C to 900°C, the heating rate is 10°C / min; from 900°C t...

Embodiment 2

[0024] Mix solid wastes such as iron tailings, shale, feldspar, mica, and foaming agent according to the mass ratio of 1:1.1:0.25:0.12:0.025 and stir evenly, add 15% water of the total mass of raw materials to granulate, and obtain After suitable plasticity, put it into a SiC mold, and burn it at 1110°C for about 3 hours, you can get a thermal conductivity of 0.114W / m·K, a compressive strength of 8.3MPa, a density of 942g / cm3, and other indicators It is also a lightweight porous thermal insulation material that meets the requirements of GB13544-2000 and GB6566-2001. Among them, the particle size of the foaming agent is less than 0.075mm, and the particle size of the remaining solid raw materials is less than 0.15mm; the solid waste is composed of iron tailings, coal gangue and old bricks and tiles according to the mass ratio of 14:3:3; the temperature system For: below 400°C, the heating rate is 5°C / min; from 400°C to 900°C, the heating rate is 10°C / min; from 900°C to 1110°C, ...

Embodiment 3

[0026] Mix solid waste such as iron tailings, shale, feldspar, mica, and foaming agent according to the mass ratio of 1:1.2:0.2:0.15:0.03 and stir evenly, add 15% of the total mass of raw materials to granulate, and obtain After suitable plasticity, put it into a SiC mold, and burn it at 1120°C for about 2 hours, you can get a thermal conductivity of 0.099W / m·K, a compressive strength of 7.5MPa, a density of 829g / cm3, and other indicators It is also a lightweight porous thermal insulation material that meets the requirements of GB13544-2000 and GB6566-2001. Wherein, the particle size of foaming agent is less than 0.075mm, and the particle size of other solid raw materials is less than 0.15mm; the solid waste is composed of iron tailings, coal gangue and cullet according to the mass ratio of 16:3:2; the temperature system is : Below 400°C, the heating rate is 5°C / min; from 400°C to 900°C, the heating rate is 10°C / min; from 900°C to 1120°C, the heating rate is 3°C / min, and keep ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com