Titanium-containing zirconium white frit and manufacturing method thereof

A technology of white frit and titanium-zirconium, which is applied in the field of opacifying glaze frit for ceramic glazed tile production and its preparation, can solve the problems of large amount of opacifying agent production, high production cost, and harm to human body, and achieve low price , low cost, and the effect of reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

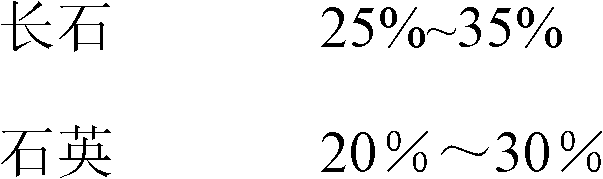

[0024] Formula: (percentage by weight)

[0025]

[0026]

[0027] Preparation:

[0028] The above raw materials are mixed, melted at 1500°C for 50 minutes, and then water quenched to obtain the frit;

[0029] 95% (weight) of the obtained frit and 5% clay are ball milled and glazed, applied on the brick adobe, and fired in a roller kiln to obtain the final ceramic glazed brick.

[0030] The whiteness is tested by the instrument Minolta CM-3300d, the whiteness reaches 85°, and the surface is smooth and white.

Embodiment 2

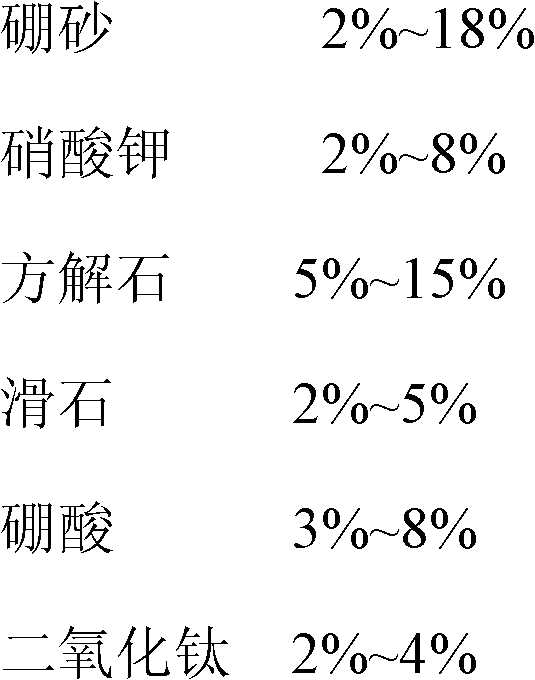

[0032] Formula: (percentage by weight)

[0033]

[0034] Preparation:

[0035] The above raw materials are mixed, melted at 1450°C for 60 minutes, and then water quenched to obtain the frit;

[0036] 95% (weight) of the obtained frit and 5% clay are ball milled and glazed, applied on the brick adobe, and fired in a roller kiln to obtain the final ceramic glazed brick.

[0037] The whiteness is tested by the instrument Minolta CM-3300d, the whiteness reaches 92.45°, and the surface is smooth and white.

Embodiment 3

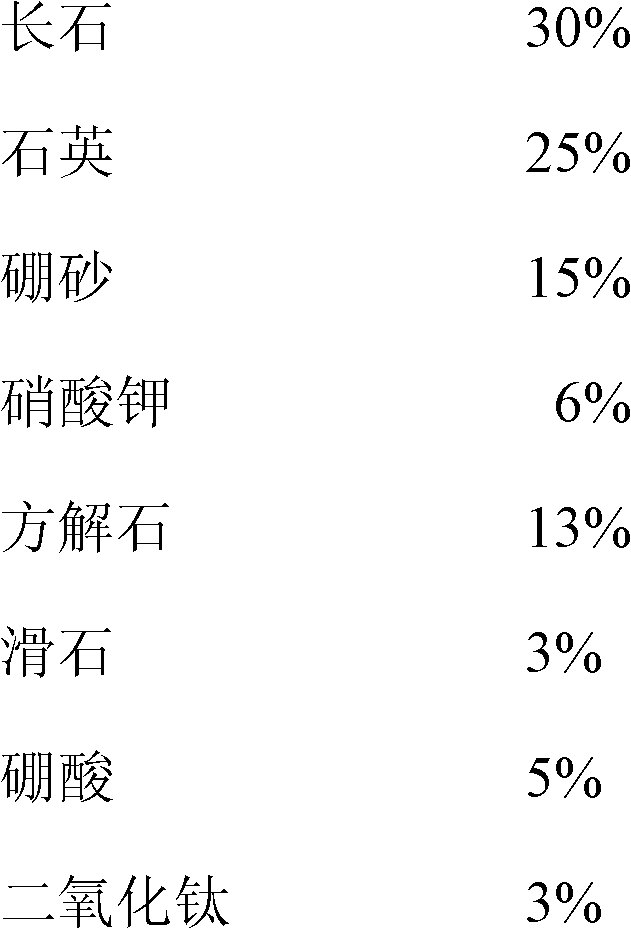

[0039] Formula: (percentage by weight)

[0040]

[0041] Preparation:

[0042] The above raw materials are mixed, melted at 1670°C for 45 minutes, and then water quenched to obtain the frit;

[0043] 95% (weight) of the obtained frit and 5% clay are ball milled and glazed, applied on the brick adobe, and fired in a roller kiln to obtain the final ceramic glazed brick.

[0044] The whiteness is tested by the instrument Minolta CM-3300d, the whiteness reaches 87°, and the surface is smooth and white.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com