Epoxy resin composition for encapsulation and electronic component device

A technology of epoxy resin and composition, applied in the direction of epoxy resin glue, electrical components, electrical solid devices, etc., can solve the problems of low fluidity, pinholes, voids, etc., and achieve excellent reflow resistance and high adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

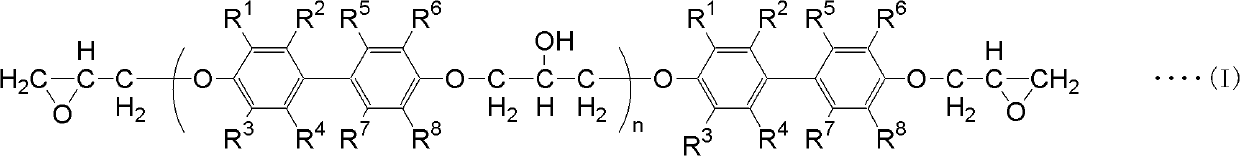

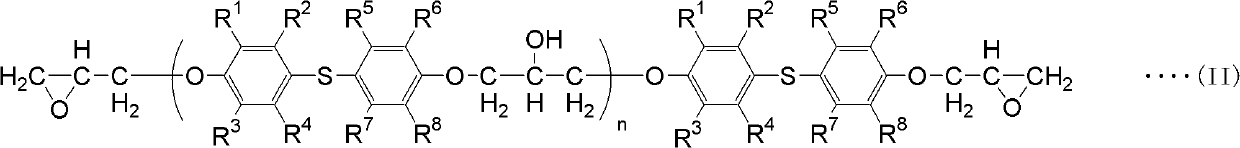

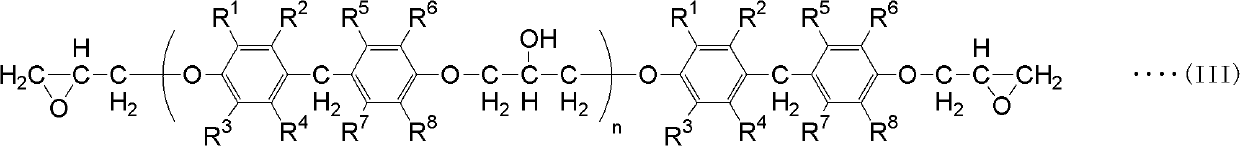

Image

Examples

preparation example Construction

[0218]

[0219] The epoxy resin composition for sealing of the present invention may be prepared by any method as long as it can uniformly disperse and mix various components. As a usual method, there may be mentioned a method of sufficiently mixing components in predetermined amounts with a mixer or the like, and then melting and kneading with a kneader, extruder or the like, followed by cooling and pulverization. For example, it can be obtained by uniformly stirring and mixing predetermined amounts of the above-mentioned components, kneading, cooling, pulverizing, and the like with a kneader, roll, extruder, etc. previously heated to 70°C to 140°C. It is easier to use if it is formed into a sheet with a size and quality corresponding to the molding conditions.

[0220]

[0221] As an electronic component device equipped with an element sealed with the epoxy resin composition for sealing obtained by the present invention, mounting of a semiconductor chip on a support memb...

Embodiment

[0225] The present invention will be described below by way of examples, but the scope of the present invention is not limited by these examples. In addition, "%" means "mass %" unless otherwise stated.

[0226]

[0227] The following components were mixed in parts by mass shown in the following Tables 1 to 6, and roll kneading was carried out at a kneading temperature of 80°C and a kneading time of 10 minutes to prepare Examples 1 to 24 and Comparative Examples 1-24 epoxy resin composition for sealing. In addition, the empty column in a table|surface shows non-combination.

[0228] As (A) epoxy resin, use:

[0229] Epoxy resin 1: a biphenyl type epoxy resin (trade name YX-4000 manufactured by Japan Epoxyresin Co., Ltd.) having an epoxy equivalent of 196 g / eq and a melting point of 106° C.,

[0230] Epoxy resin 2: a biphenylene skeleton-containing phenol-aralkyl type epoxy resin (trade name CER-3000L manufactured by Nippon Kayaku Co., Ltd.) with an epoxy equivalent of 240...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com