High-temperature steam resistant environment-friendly emulsion paint for interior walls

An environmentally friendly latex and high temperature resistant technology, applied in latex paint, coating, etc., can solve the problems of waste of non-renewable resources, harmful substances, emissions, etc., and achieve excellent high temperature steam resistance, low VOC, and good decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

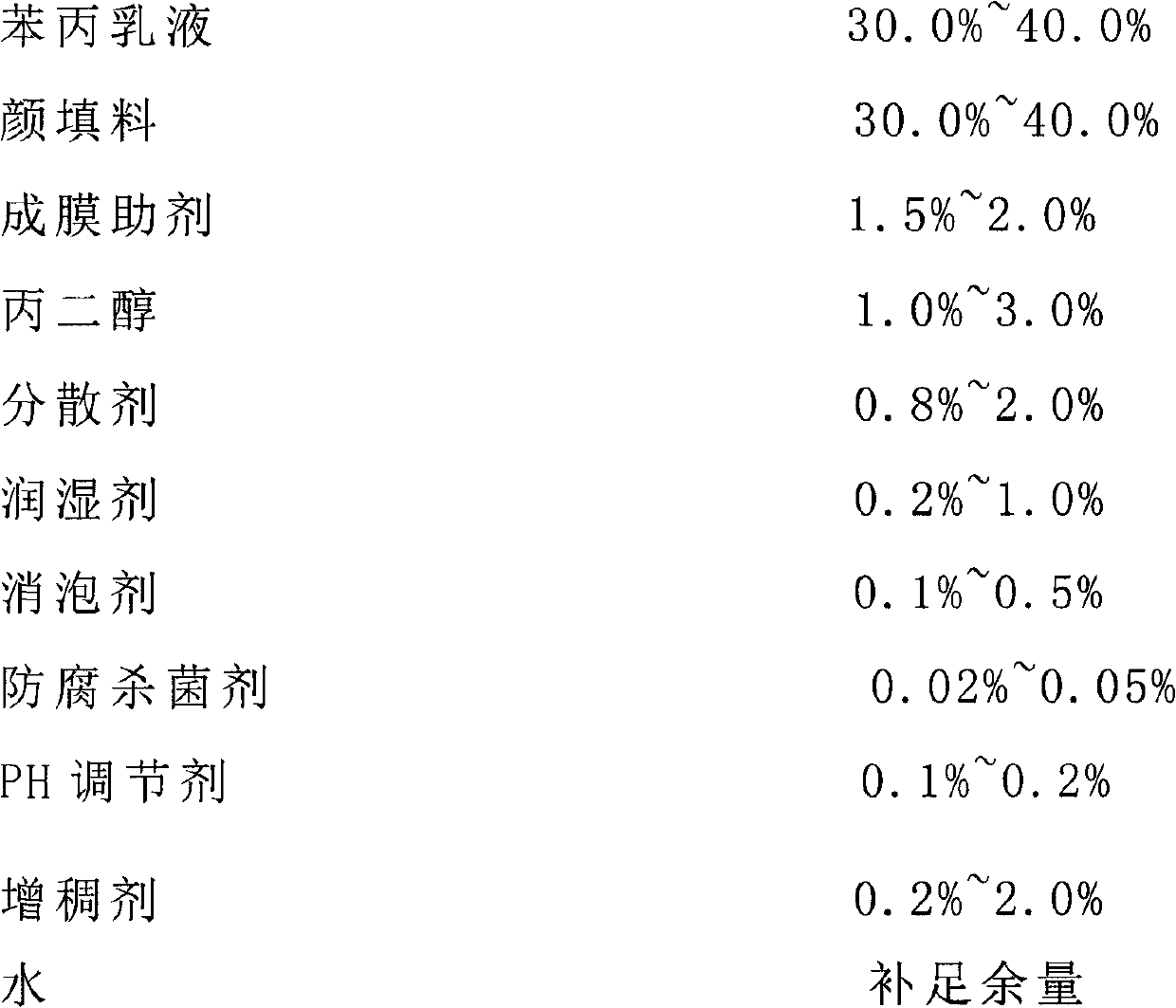

Method used

Image

Examples

example 1

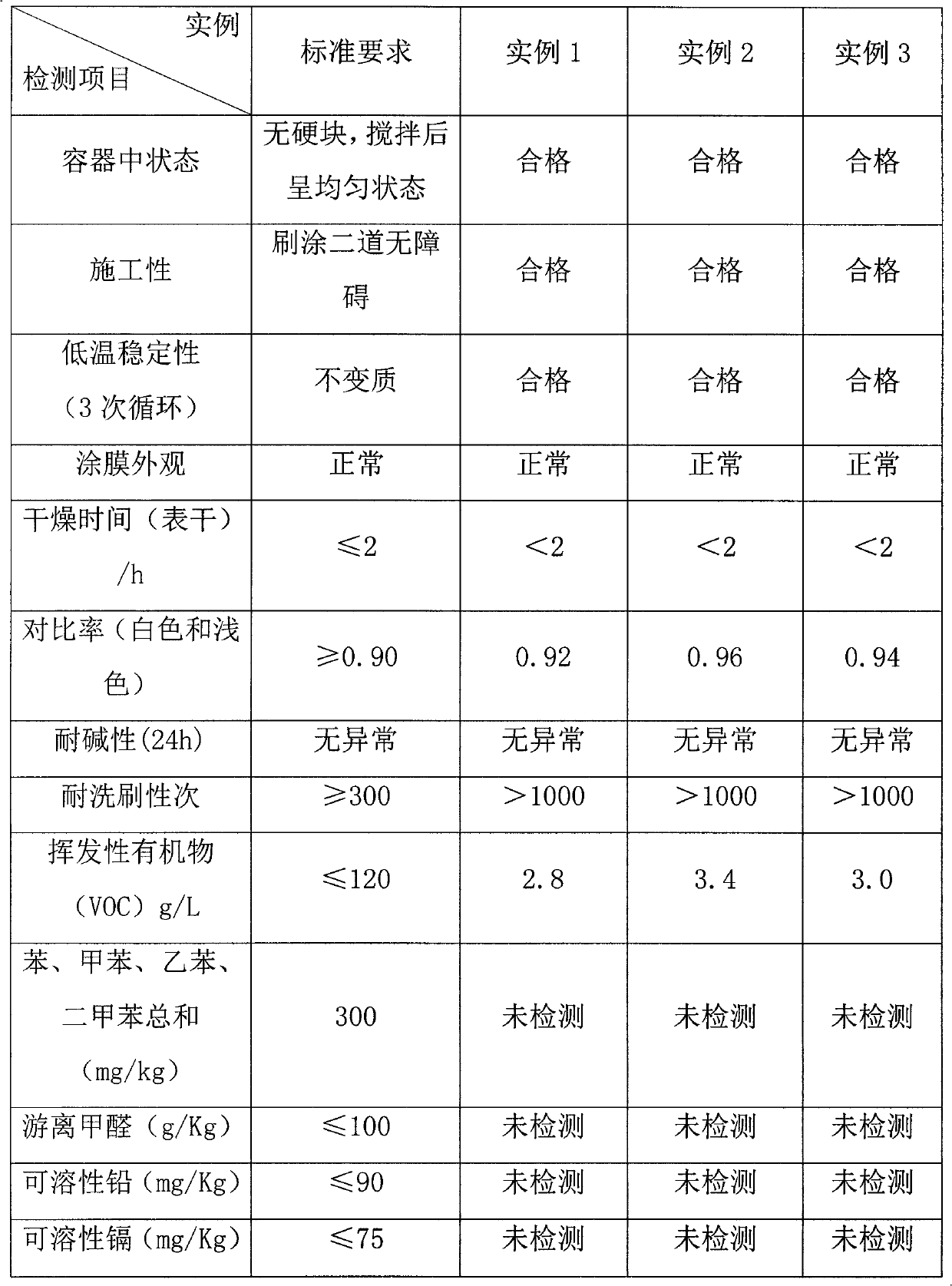

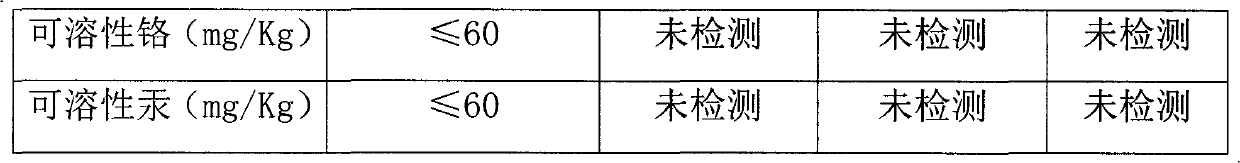

[0030] Weigh 35.0 parts of water based on 100 parts by weight, and add dispersant 5027: 1.0 part, thickener NATROSAL 250HBR: 0.2 part, wetting agent WET 996: 0.6 part, Defoamer DEFOAMER 154S: 0.2 parts, propylene glycol: 1.0 parts, disperse for 5 minutes; at 600-1000 rpm, add rutile titanium dioxide R-902: 20.0 parts, kaolin: 8.0 parts, heavy calcium powder: 2.0 parts; at 1000-1300 rpm, disperse for 20-30 minutes; sampling inspection fineness ≤ 50 microns; at 300-600 rpm At the rotating speed of 100°C, add styrene-acrylic emulsion RS-998A: 30.0 parts, film-forming aid TEAXNAL: 1.5 parts, antiseptic and bactericide EPWKathon TM LXE: 0.02 parts, disperse for 5 minutes, add PH regulator AMP-95: 0.18 parts, defoamer DEFOAMER 154S: 0.2 parts, thickener THICKENER 629N: 0.1 parts, disperse for 5 minutes; sample inspection; filter and pack after passing . The testing methods, items and testing results of the latex paint are shown in attached tables 1 and 2.

example 2

[0032] Weigh 25.0 parts of water based on 100 parts by weight, and put in dispersant Dispersant 5029: 1.0 part, thickener NATROSAL 250HBR: 0.2 part, wetting agent WET 997: 0.2 part, Defoamer A10: 0.2 parts, propylene glycol: 1.0 parts, disperse for 5 minutes; put in rutile titanium dioxide at a speed of 600-1000 rpm R-902: 20.0 parts, talcum powder: 5.0 parts, kaolin: 5.0 parts; at 1000-1300 rpm, disperse for 20-30 minutes; sampling inspection fineness ≤ 50 microns; at 300-600 rpm Under the rotating speed, add styrene-acrylic emulsion 998A: 40.0 parts, film-forming aid TEAXNAL: 1.8 parts, antiseptic and fungicide EPWKathon TM LXE: 0.04 parts, dispersed for 5 minutes, PH regulator AMP-95: 0.16 parts, defoamer DEFOAMER 154S: 0.2 parts, thickener THICKENER 629N: 0.2 parts, dispersed for 5 minutes; sample inspection; filter and pack after passing. The testing methods, items and testing results of the latex paint are shown in attached tables 1 and 2.

example 3

[0034] Weigh 24.0 parts of water based on 100 parts by weight, and put in dispersant Dispersant 5029: 0.86 parts, thickener NATROSAL 250HBR: 0.2 parts, wetting agent WET 997: 0.2 parts, Defoamer DEFOAMER 154S: 0.2 parts, propylene glycol: 1.0 parts, disperse for 5 minutes; at 600-1000 rpm, add rutile titanium dioxide R-902: 34.0 parts, talcum powder: 2.0 parts; at 1000-1300 rpm, disperse for 20-30 minutes; sampling inspection fineness ≤ 50 microns; at 300-600 rpm, add in sequence Styrene-acrylic emulsion 818: 35.0 parts, film-forming aid TEAXNAL: 1.8 parts, antiseptic and fungicide EPWKathon TM LXE: 0.04 parts, dispersed for 5 minutes, PH regulator AMP-95: 0.1 parts, defoamer DEFOAMER 154S: 0.2 parts, thickener THICKENER 629N: 0.4 parts, dispersed for 5 minutes; sample inspection; filter and pack after passing. The testing methods, items and testing results of the latex paint are shown in attached tables 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com