Composite fiber with effect of keeping warm

A composite fiber and mixing ratio technology, applied in the field of textile fabrics, can solve the problems of sacrificing air permeability, unfavorable thermal performance and long-term warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

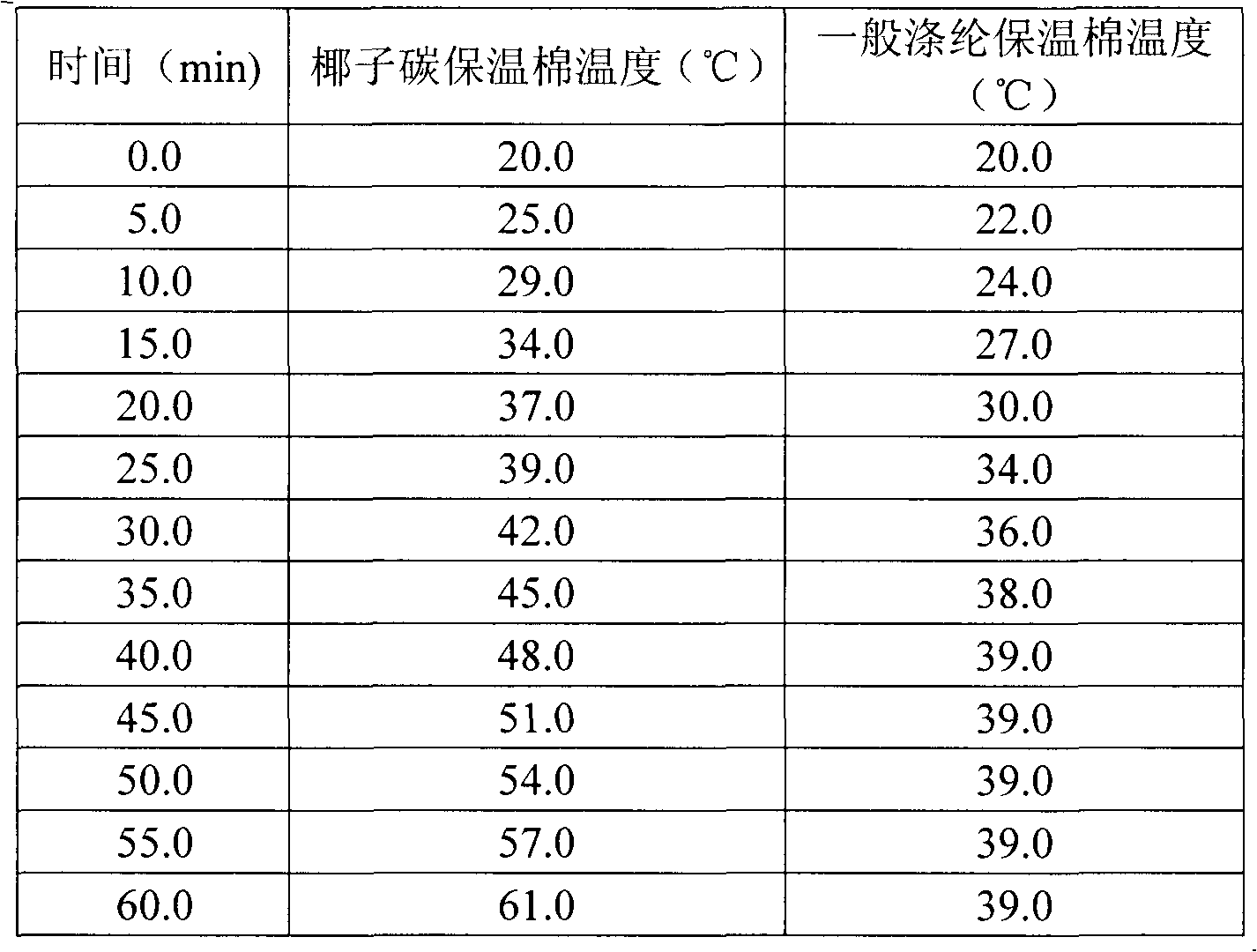

[0027] Embodiment 1-3: a kind of composite fiber with warming effect, described composite fiber is obtained by following process, and this process comprises the following steps:

[0028] Step 1, the fiber of coconut shell is heated at high temperature to obtain coconut carbon powder;

[0029] Step 2, uniformly mix polyester chips, silane coupling agent, zinc stearate as surfactant and liquid wax as dispersant at high temperature to form molten polyester; the mixing mass ratio is shown in Table 1 :

[0030] Table 1

[0031] Polyester chips

liquid wax

Example 1

100

0.39

2.8

6.8

Example 2

100

0.41

2.75

6.9

Example 3

100

0.40

2.7

7

[0032] Step 3, uniformly mixing the coconut carbon micropowder and molten polyester according to the mass ratio of 1: 3.8 to 4.2 to form a mixture;

[0033] Step 4, the mixture is weaved t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com