Operating circuit for micro electronic mechanical system (MEMS) scanning micro-mirror spectrometer

A technology for scanning micromirrors and working circuits, applied in the field of spectral analysis instruments, can solve problems such as increasing the complexity of the instrument structure and increasing the difficulty of designing working circuits, and achieves the effects of reducing the difficulty of design, improving spectral repeatability, and simplifying the system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

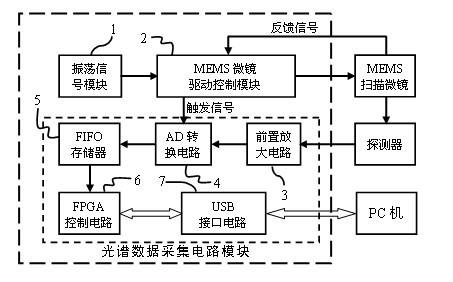

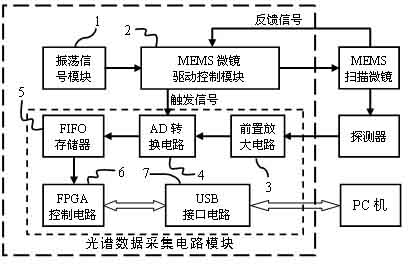

[0027] Such as figure 1 Shown is the circuit principle diagram of the working circuit of the MEMS scanning micromirror spectrometer of the present invention.

[0028] The working circuit of the MEMS scanning micromirror spectrometer is mainly composed of three modules: an oscillation signal module 1, a MEMS micromirror drive control module 2, and a spectral data acquisition module. It is composed of conversion circuit 4, FIFO memory 5, FPGA control circuit 6 and USB interface circuit 7. The oscillating signal module 1 provides an oscillating signal with a specific frequency for the MEMS micromirror drive control module 2, and the oscillating signal is divided into two channels after signal processing by the MEMS micromirror drive control module 2, one for the MEMS micromirror. The other way provides a periodic trigger signal for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com