Temperature measuring device based on high-pressure gas Rayleigh-Brillouin scattering spectrum

A Brillouin scattering and gas temperature technology, applied in the field of experimental devices, can solve problems such as unsatisfactory measurement results, and achieve the effects of improving reliability, stability, high resolution, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

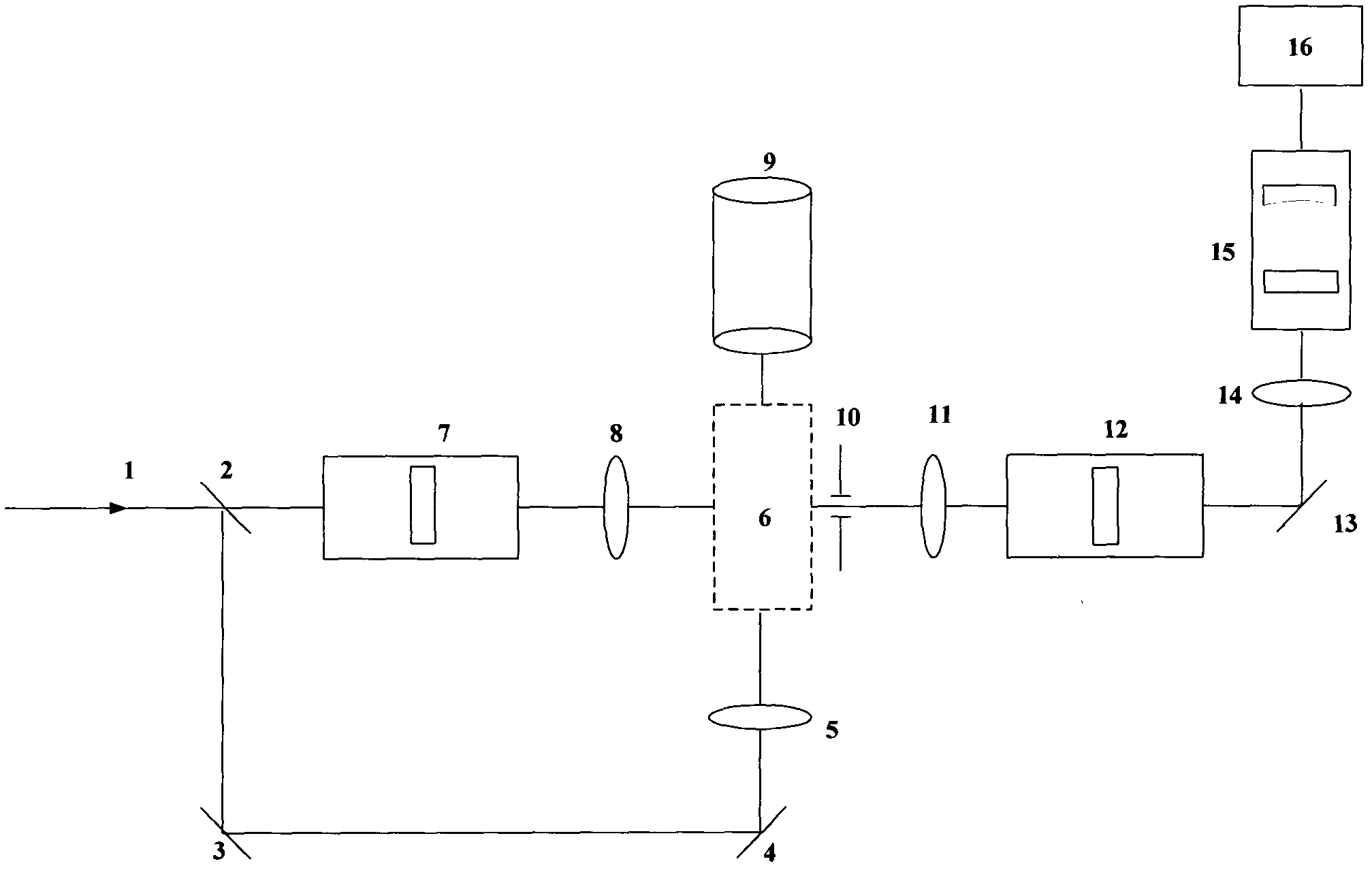

[0021] as attached figure 1 As shown, the device includes: injection pulse laser or continuous laser (1), 355nm total mirrors (2, 3, 4, 13), filter system (7), collimation and filter system (12), Slits (10, 18, 21, 23), convex lenses (5, 8, 11, 14, 17, 19, 20, 22), scattering cells (6), scanning interferometers (15), energy recovery cells (9) , Signal detection device (16).

[0022] The laser (1) outputs vertically polarized narrow-band light with a wavelength of 355nm, 95% of the light is reflected to the total reflection mirror (3) through the 355nm total reflection mirror (2), and 5% of the light is transmitted to the filter system (7) , after passing through the convex lens (8), it enters into the scattering pool (6) for correction of the optical path. The light passing through the total reflection mirror (3) passes through the total reflection mirror (4) and the focusing lens (5), and enters the scattering cell (6), interacts with gas molecules to generate a scattering ...

Embodiment 2

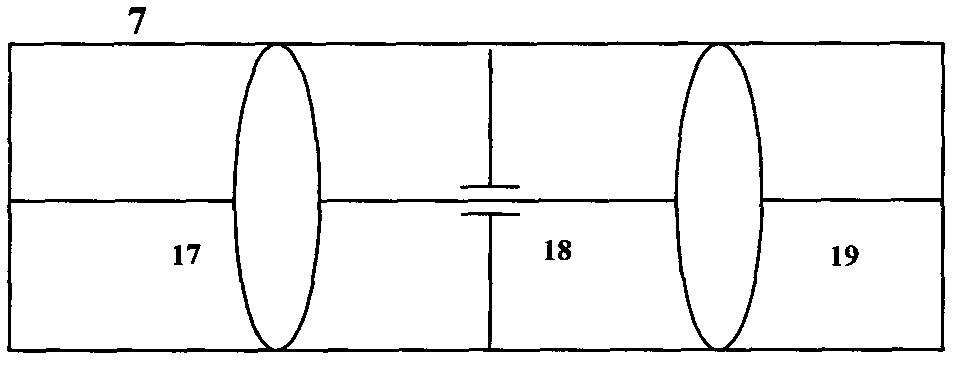

[0024] as attached figure 2 Shown, filter system (7) comprises: convex lens (17,19) and slit (18)

[0025] In order to calibrate the experimental device in the experiment, 5% of the light is set as reference light, and in order to ensure the quality of the laser beam, 5% of the laser light passes through the convex lens 17 (f 17 =10cm), slit 18(D 18 =50um), convex lens 19 (f 19 =10cm) to filter the spatial filtering system, the purpose is to eliminate the spatial fluctuation of the beam and make the field intensity distribution on the section uniform.

Embodiment 3

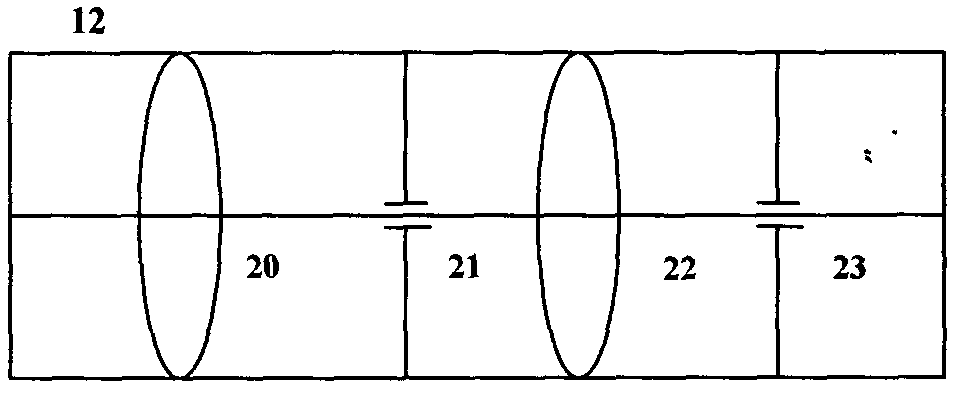

[0027] as attached image 3 As shown, the light filtering and light spot diameter integration system (12) includes: convex lenses (20, 22) and slits (21, 23).

[0028] In order to detect the weak scattering signal in the experiment and realize the detection of the Brillouin scattering signal, the scattering signal must be coupled into the high-resolution spectroscopic system (15) as much as possible, so the slit 10, Lens 11 (D 10 = 0.1 mm, f 11 =75mm) and filter and light spot diameter integration system (12), the signal first passes through the slit 10 (D 10 =0.1mm) reduces the spatial divergence angle, is collimated by the lens 11 (f=75mm), and then is collimated by the lens 20 (f 20 =50mm) focus to the slit 21 (D 21 =50um) to carry out spatial filtering, finally by the lens 22 (f 22 =50mm) collimated again, in order to limit the diameter of the spot within the acceptable range of the scanning interferometer, pass it through the slit 23 (D 23 =1.5mm) to correct the spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com