Modified Pt-based fuel-cell catalyst and preparation methods thereof

A fuel cell and catalyst technology, applied in the field of electrochemistry, can solve the problems of reduced catalytic activity, poor methanol oxidation kinetics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

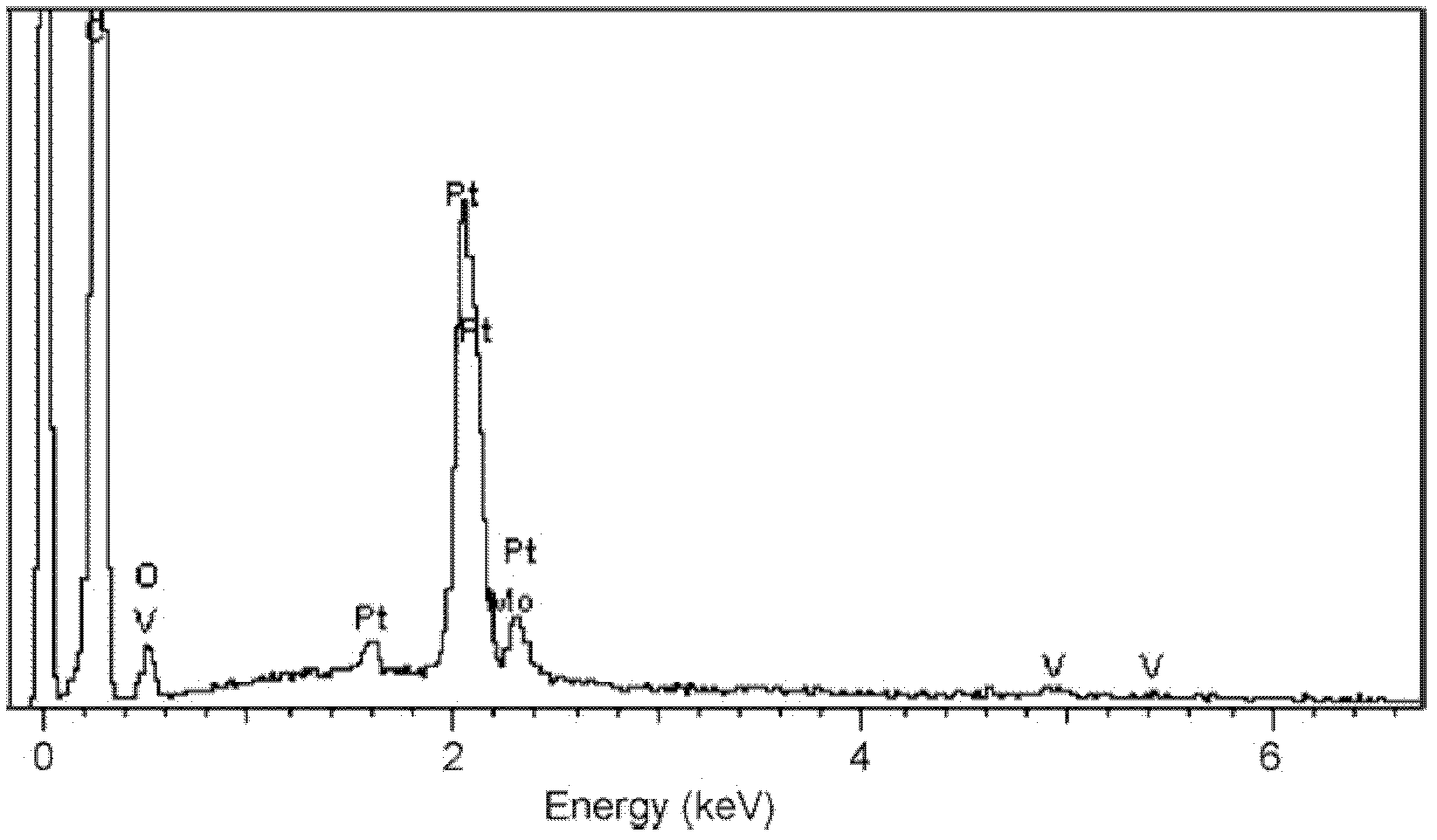

[0046] The Pt-based catalyst was modified by physical adsorption method: the catalyst was a Pt / C catalyst (20% Pt mass content) from a commercial E-teck company, and the heteropolyacid was H 5 PMo 10 V 2 O 40 . Disperse 50mgPt / C catalyst in 20mgml-1 of H 5 PMo 10 V 2 O 40 The solution was fully immersed for 12 hours under mechanical stirring. The mixture is then filtered, and the solid material is dried to obtain H 5 PMo 10 V 2 O 40 Modified Pt / C catalyst. figure 1 for H 5 PMo 10 V 2 O 40 EDX image of the modified Pt / C catalyst, from which obvious Pt, Mo, V peaks can be seen, proving that H 5 PMo 10 V 2 O 40 adsorbed onto the Pt / C catalyst. Disperse 5 mg of the catalyst in a mixture of 1 mL of ethanol and 50 μL of Nafion solution with a mass fraction of 5%, and perform ultrasonic dispersion to prepare a catalyst ink; take 10 μL of the catalyst ink and drop it on the surface of the glassy carbon electrode to prepare a catalyst electrode for methanol Electro...

Embodiment 2

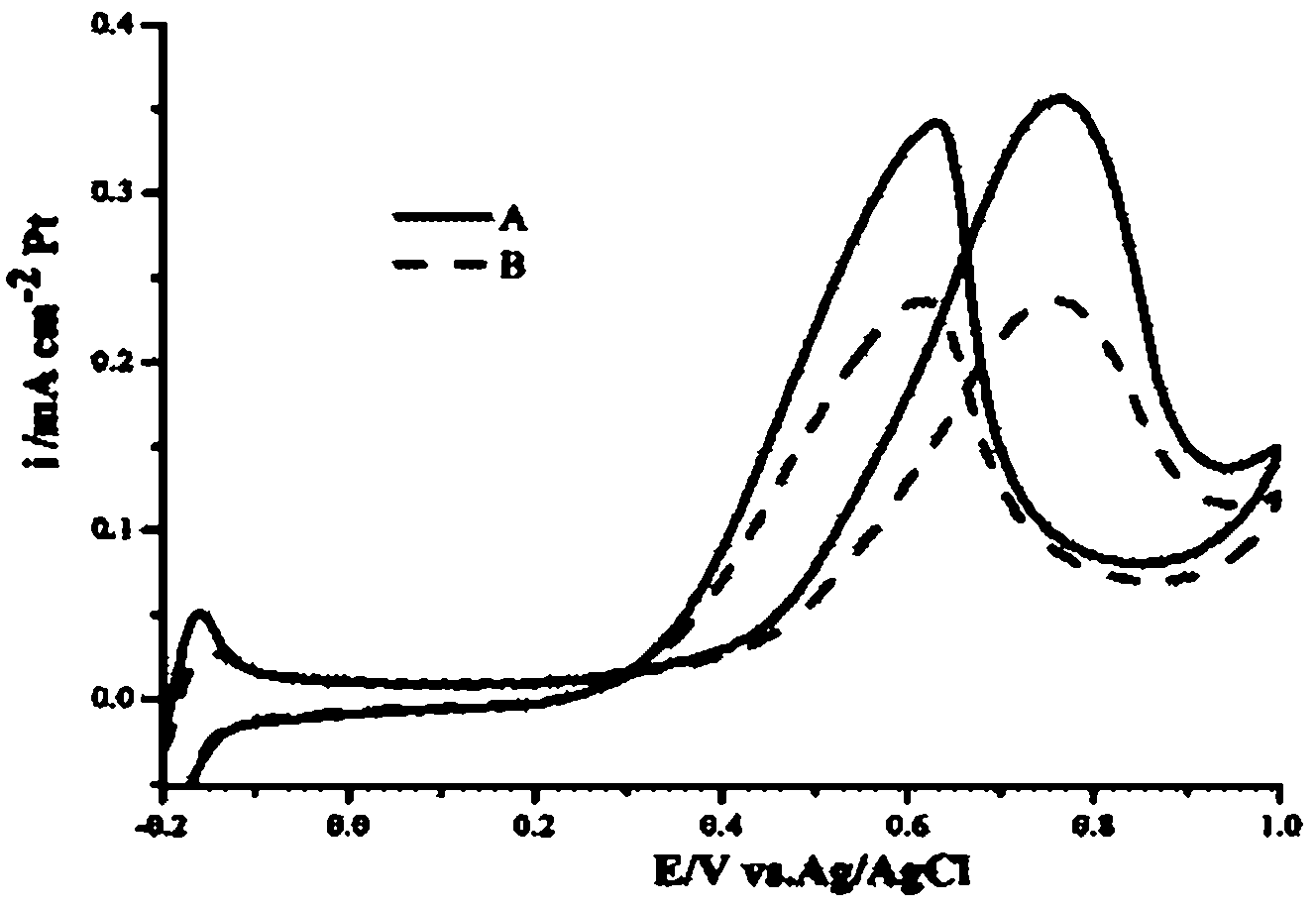

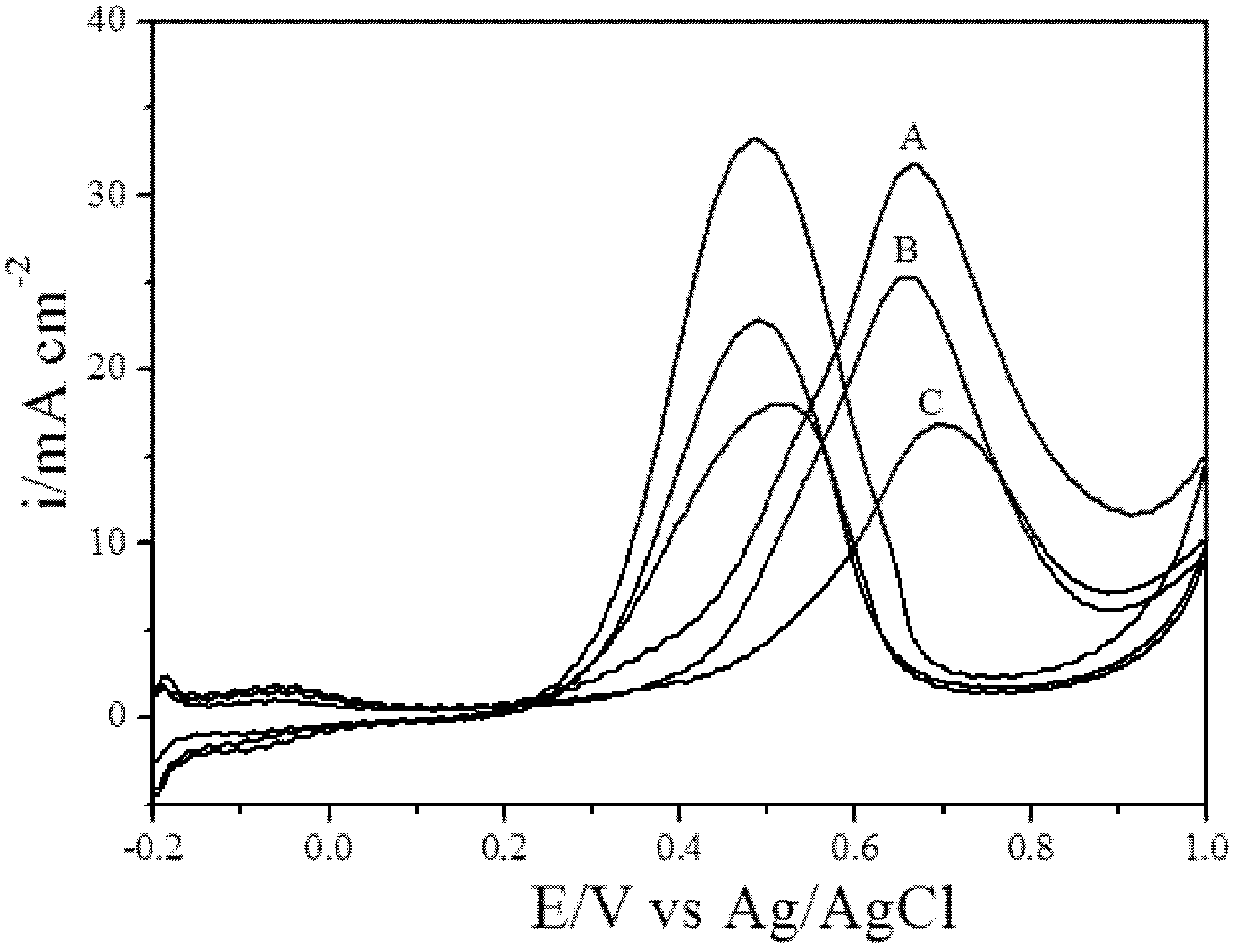

[0048] Modification of Pt-based catalyst by electrochemical method: Disperse 5 mg of the above commercial Pt / C catalyst in a mixture of 1 mL of ethanol and 50 μL, and ultrasonically disperse to make catalyst ink; take 10 μL of catalyst ink and drop it on the surface of glassy carbon electrode to make Catalyst electrode. The electrode was placed in 10 mg ml-1 of H 3 PMo 12 O 40 , H 4 PMo 11 V 1 O 40 Electrochemical cyclic voltammetry scanning was carried out in the heteropolyacid solution, the scanning potential was -0.2-1.0V, at 20mv s -1 Continuous scanning was carried out until the electrochemical behavior was stable, and finally the Pt-based catalyst electrocatalyst modified by the heteropolyacid was obtained. The catalyst electrode was used for the electrocatalytic oxidation of methanol, image 3 is the modified catalyst H 5 PMo 10 V 2 O 40 (A), H 3 PMo 12 O 40 (B) Cyclic voltammograms of electrocatalytic oxidation of methanol with unmodified Pt / C catalyst (C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com