Cabinet body of high-voltage switch cabinet

A technology for high-voltage switch cabinets and cabinets, which is applied to substation/switch layout details, electrical components, substation/power distribution device shells, etc. It can solve the problems of large welding deformation, prolonging the manufacturing cycle, and long production cycle to reduce manufacturing costs. cost, increase production efficiency, reduce the effect of production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

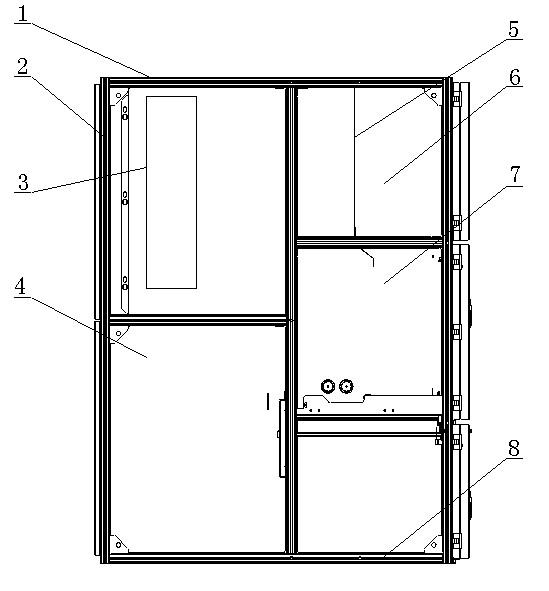

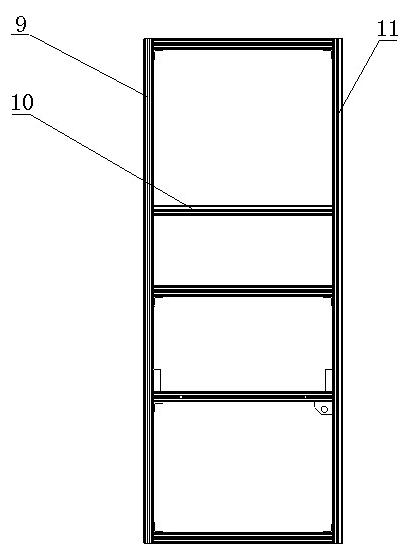

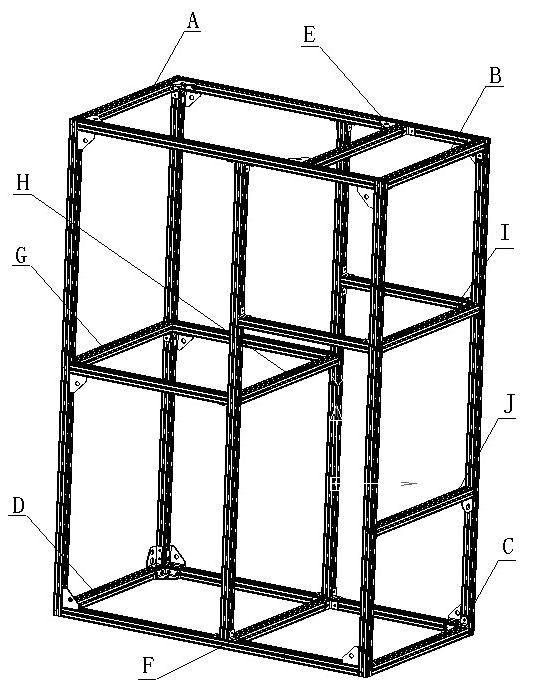

[0015] Control attached figure 1 , its structure is the framework of the whole switchgear composed of the profile frame 2, the top plate 1 of the cabinet body is installed on the top surface of the profile frame 2, and the side plates 3 of the bus room are installed symmetrically in the upper rear gap of the profile frame 2. Two pieces of cable room side panels 4 are symmetrically installed in the gap at the rear lower part of the profile frame 2, and two instrument box side panels 6 are installed symmetrically in the gap at the front upper part of the profile frame 2. The instrument box relay board 5 is installed between the left and right instrument box side panels 6 through screws, and the circuit breaker room side panels 7 are installed symmetrically in the gap at the front lower part of the profile frame 2, and the cabinet bottom plate 8 is installed on the profile The bottom surface of the frame 2; among them, the side plate of the busbar room 3, the side plate of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com