Method for welding flange of wind driven generator tower

A technology of wind power generators and welding methods, which is applied to welding equipment, arc welding equipment, and the edge of workpieces, etc., can solve the problems of decreased reliability of tower tubes, affecting connection reliability, and high labor intensity of workers. Low labor intensity, good reliability of flange connection, saving time and labor in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

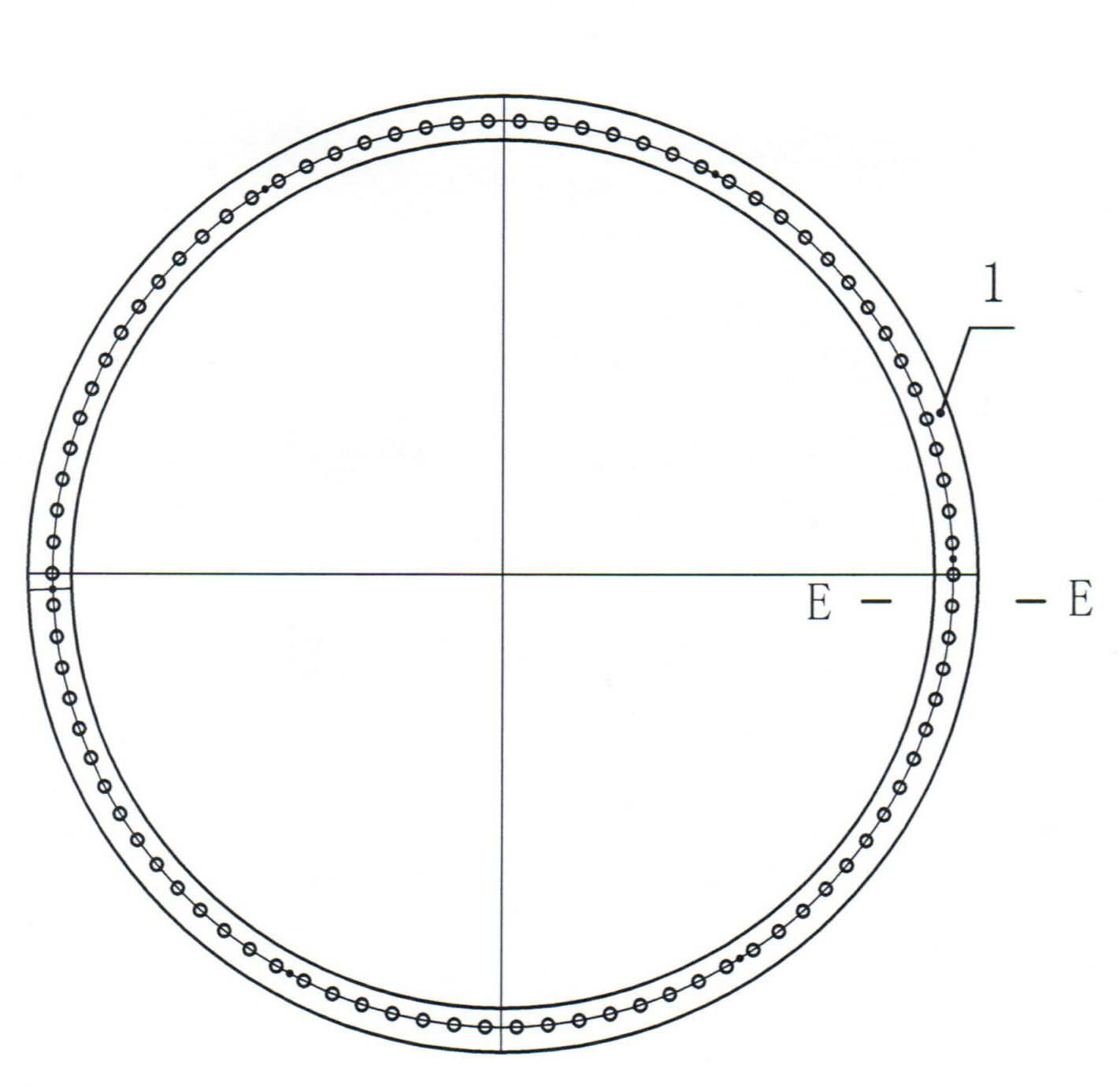

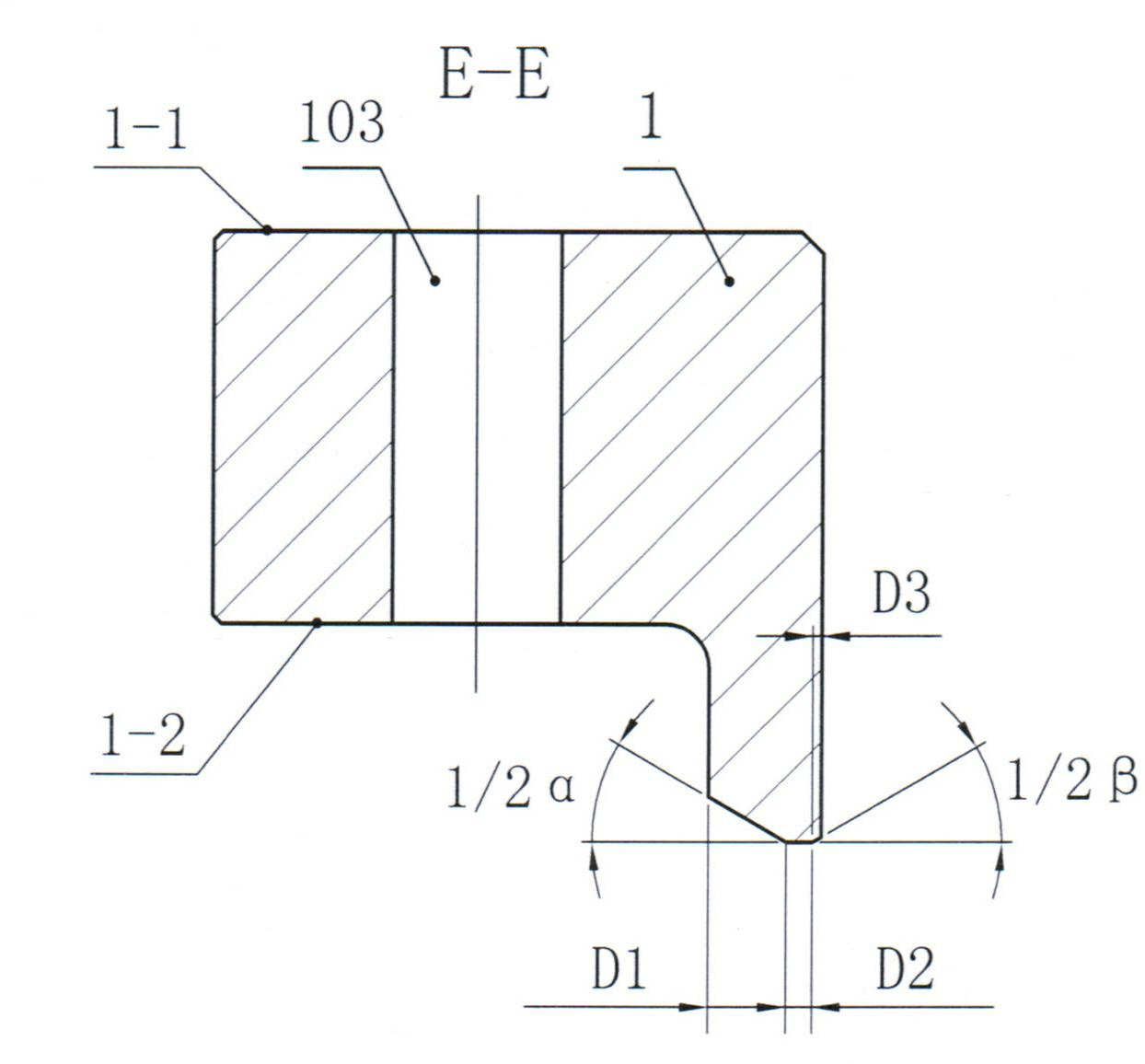

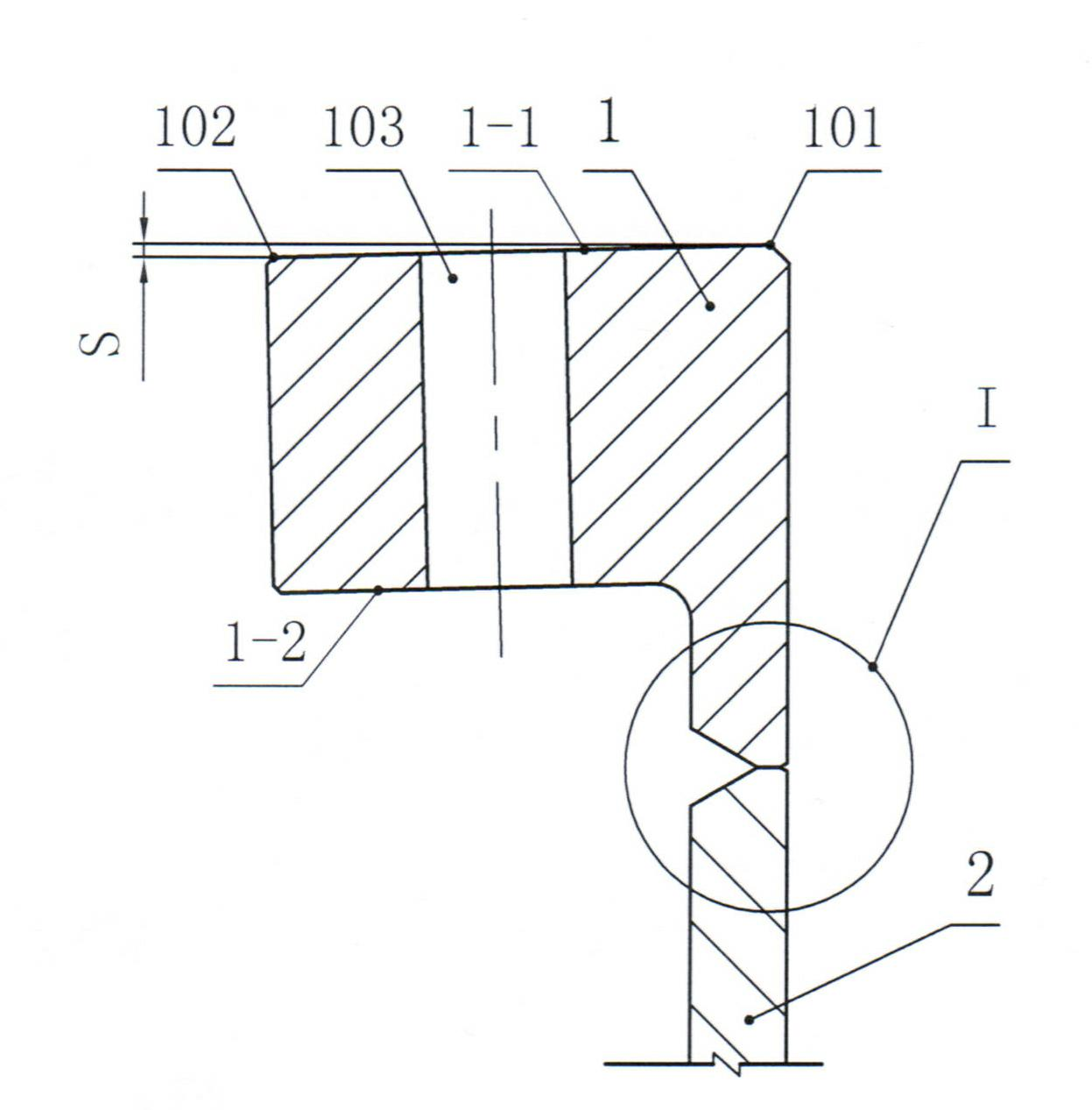

[0036] like Figure 1~5 As shown, a welding method of a wind turbine tower flange is a method of welding an inner flange 1 on each section of the tower body 2 forming the tower to produce an inwardly inclined flange. The steps of the welding method are as follows :

[0037] A. Beveling:

[0038] ——Take the inner flange 1 whose upper surface 1-1 and lower surface 1-2 are parallel, and make a Y-shaped bevel on the inner side of the inner flange 1 and the horizontal end surface 3 of the tower body 2, and make a Y-shaped bevel on the inner side of the horizontal end surface 3 There is a small V-shaped groove on the outside;

[0039] When opening the groove in this step, the horizontal distance of the small V-shaped groove on the outside of the horizontal end surface 3 is D3, and the horizontal distance of the horizontal end surface 3 between the Y-shaped groove and the small V-shaped groove is D2, Y The horizontal distance of the groove is D1, D1>D2>D3. The slope angle α of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com