Electric furnace structure used for fluoridated salt production and manufacturing method of electric furnace

A production method and fluoride salt technology, applied in the direction of aluminum fluoride, aluminum halide, etc., can solve the problems of easy damage of graphite crucible and refractory materials, failure to prevent leakage of fluoride salt, frequent replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

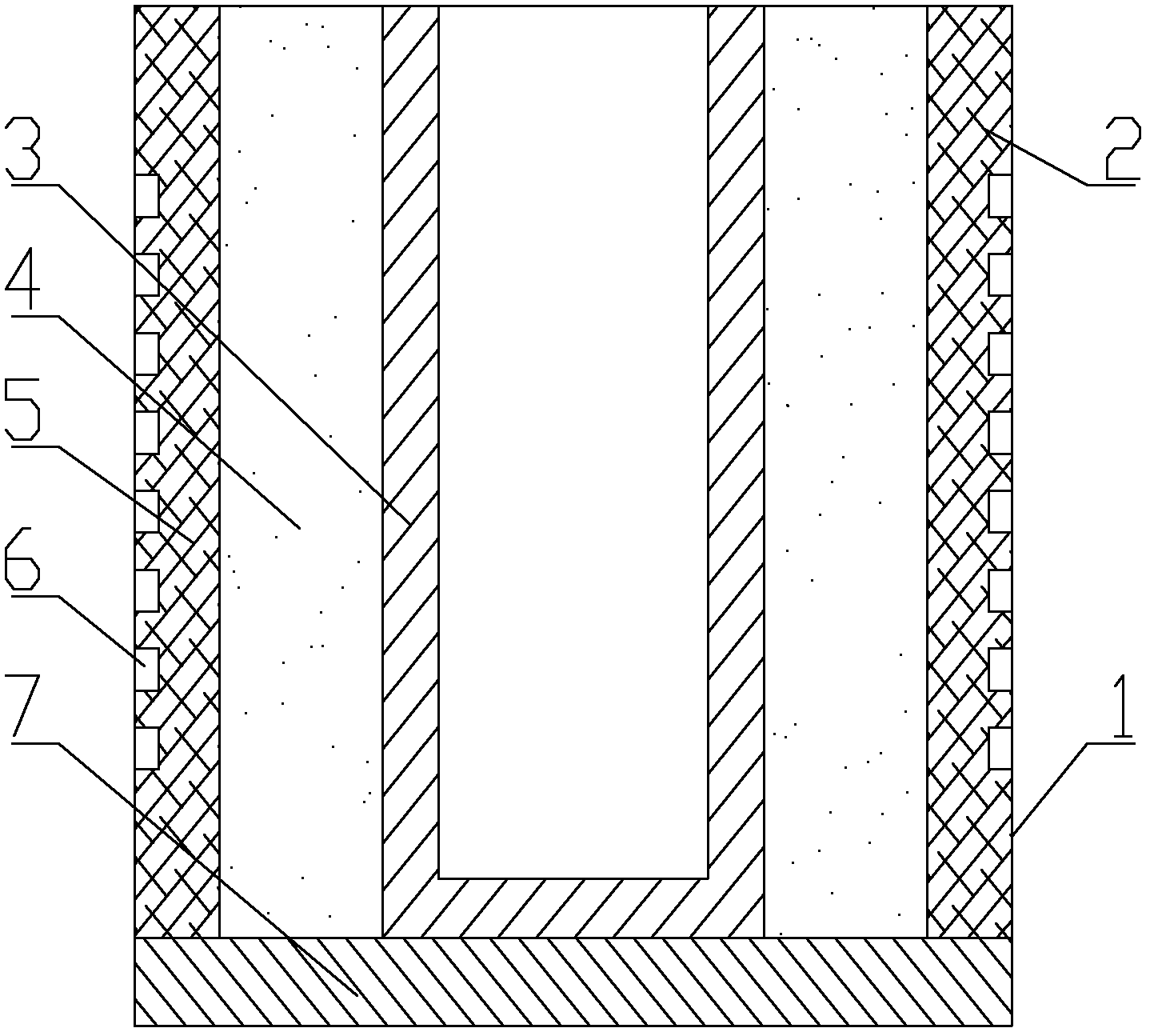

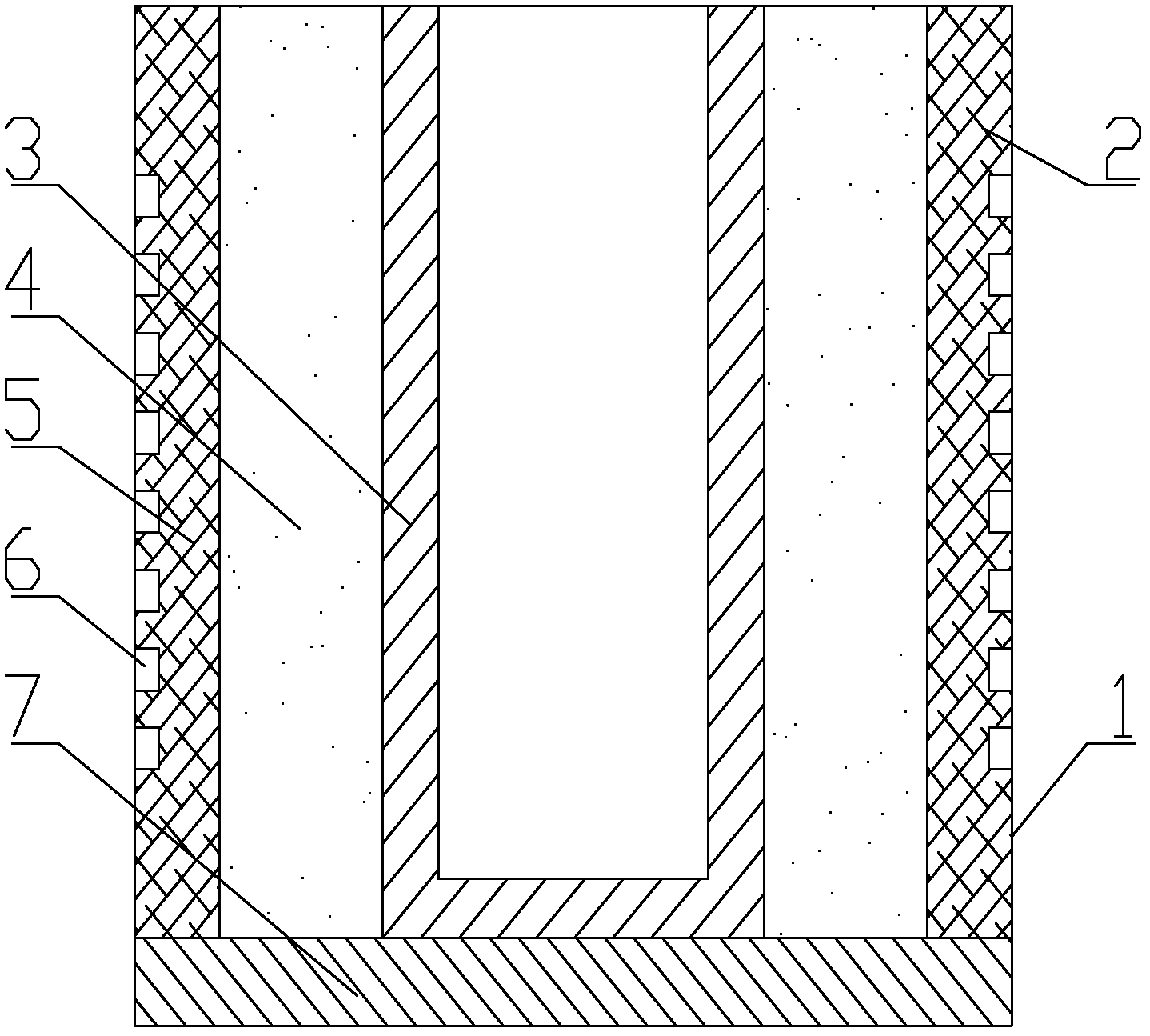

[0013] Embodiment of the present invention. The manufacturing method of the electric furnace structure for the production of fluoride salt of the present invention includes installing an induction coil layer 2 on the furnace body 1, placing a graphite crucible 3 in the middle of the furnace body 1, and putting it between the induction coil layer 2 and the graphite crucible 3 Calcium oxide layer 4. For the calcium oxide layer 4, freshly fired, moisture-free, and high-purity quicklime is selected.

[0014] When installing the induction coil layer 2, build the induction coil 6 on the outside of the refractory cement 5, leave the side of the induction coil 6 on the outside of the furnace body 1, and expose it to the refractory cement 5, so that the molten fluoride touches induction After the coil 6, the fluoride can flow out from the outside of the induction coil 6, instead of accumulating at the induction coil 6, and finally cause an explosion.

[0015] The carbon powder layer 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com