Method for preparing lithium titanate (Li4Ti5O12) with large specific area

A large specific surface area, lithium titanate technology, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems of small specific surface area of lithium titanate, easy growth of product particles, easy collapse of pore structure, etc., to achieve The effect of low preparation cost, low cost and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 5g K 2 TiO 3 Mix with 200ml of 1M hydrochloric acid solution, perform ion exchange at room temperature, and filter after 2 hours to obtain compound H 2 TiO 3 ; put 3g H 2 TiO 3 Place in 2M lithium hydroxide solution, stir or ultrasonically mix, in order to make the mix uniform, mix under the conditions of vacuum and 100°C water bath (30 minutes). Put the fully mixed reactants in a hydrothermal kettle, put them in a muffle furnace at 120°C for 10 hours, then filter them with suction and wash them with water to obtain Li 4 Ti 5 o 12 .

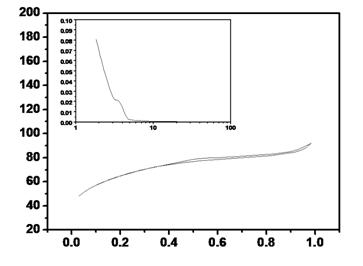

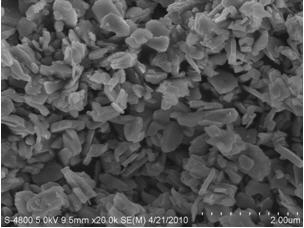

[0032] Gained Li 4 Ti 5 o 12 The BET and FESEM characterizations as figure 1 , figure 2 As shown, its BET specific surface area is 220 m 2 / g; pore volume 0.107m 3 / g; average pore size 3.3 nm.

[0033]

Embodiment 2~5

[0035] According to the substantially same method as embodiment 1, adopt H 4 Ti 5 o 12 or H 2 Ti 2 o 5 As the titanium source, change the lithium source and reaction conditions to prepare Li with different specific surface areas 4 Ti 5 o 12 , the specific conditions and product characteristics are shown in Table 1.

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com