Method for treating waste water during production of chlorpyrifos

A technology for the production of wastewater and treatment methods, applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of long process chain, high investment cost and operation cost, and complicated process steps and other problems, to achieve the effect of short process chain, low cost and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

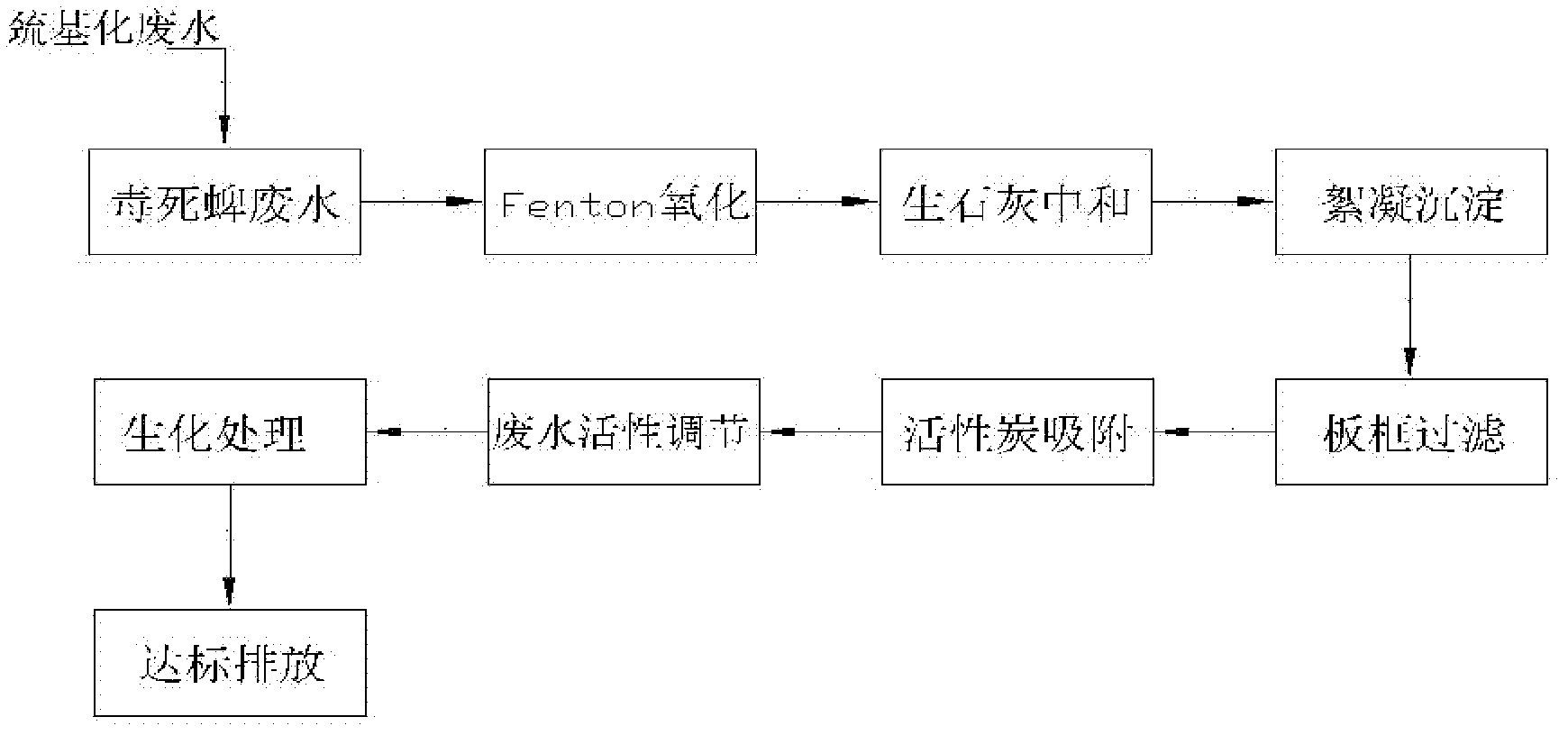

Method used

Image

Examples

Embodiment 1

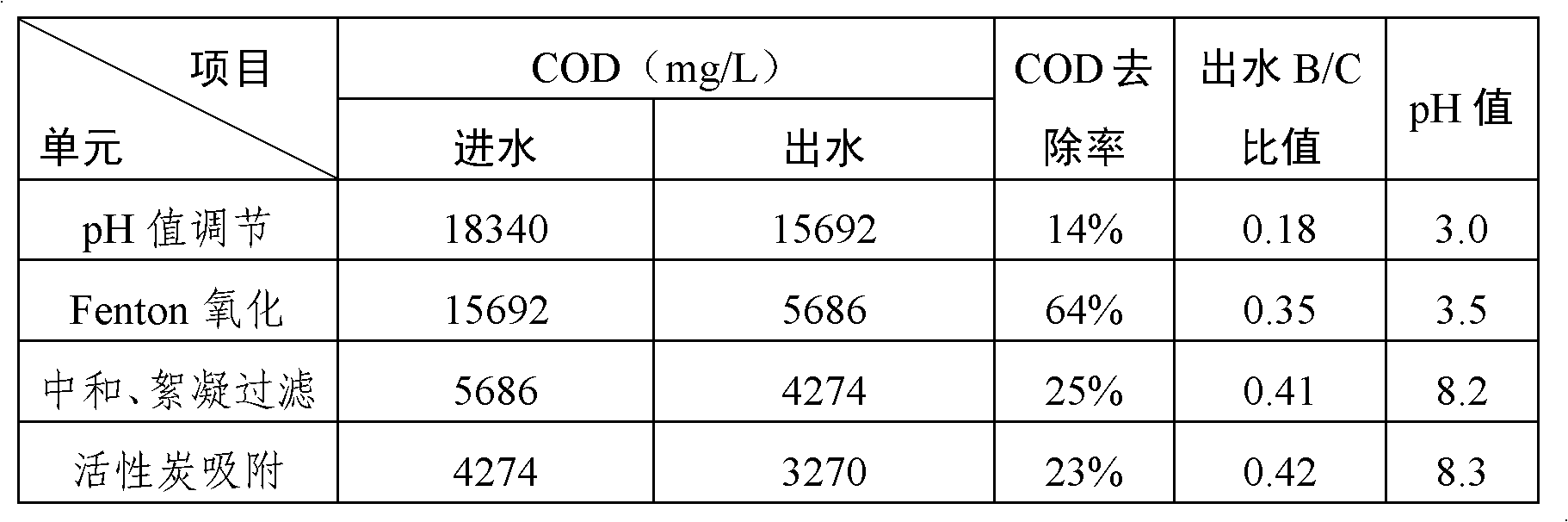

[0036] Embodiment 1 laboratory conditions

[0037] Take 1L of chlorpyrifos condensation wastewater and place it in a beaker. Take 500mL of isooctyl thioglycolate thiolation wastewater, and slowly pour it into chlorpyrifos wastewater, adjust the pH value of chlorpyrifos wastewater to 3.5, after standing for 12 hours, take the supernatant in another beaker, and then add 30% Hydrogen peroxide 3g / L, add ferrous sulfate 0.4g / L, oxidize for 5 hours, then add quicklime (0.3g / L) to it for neutralization and flocculation precipitation for 4 hours, then filter the flocculated waste water (through plate Frame filter press to filter and separate part of the organic matter), and then circulate the filtered wastewater through the activated carbon column for 50 minutes (same hydraulic retention), the influent flow rate is 5m 3 / h.

[0038]The treated waste water was taken and analyzed for COD of 3270mg / L and B / C of 0.42, meeting the requirements of biochemical treatment. The total removal...

Embodiment 2

[0042] Using chlorpyrifos production wastewater as water to be treated, the specific steps for pretreatment are as follows:

[0043] (1) pH value adjustment: use thiolated acidic wastewater to adjust the chlorpyrifos wastewater, and control the pH value of the wastewater at 3.2;

[0044] (2) Fenton oxidation: The adjusted wastewater enters the Fenton oxidation pond, and 30% hydrogen peroxide 3g / L, ferrous sulfate 0.4g / L are added to the Fenton oxidation pond, oxidized for 6 hours, and the influent flow rate is controlled to 5m 3 / h;

[0045] (3) Neutralization, flocculation and filtration: the oxidized wastewater enters the neutralization tank, and quicklime (0.3g / L) is added to the tank for neutralization, and the pH value of the pool water is controlled to be 8.2; the neutralized wastewater is Flocculation precipitation occurs under alkaline conditions, and after 5 hours, part of the organic matter is separated by plate and frame filtration;

[0046] (4) Activated carbon a...

Embodiment 3

[0051] Using chlorpyrifos production wastewater as water to be treated, the specific steps are as follows:

[0052] (1) Chlorpyrifos wastewater is introduced into the sedimentation tank (the length and width of the pool are 5m and 9m, divided into 2 compartments, and the cross-section of the overflow port is 50cm * 30cm), and the control HRT is 30 minutes; the remaining treatment scheme is the same as in Example 2 ;

[0053] (2) The wastewater after adsorption is treated by biochemical (A / O method) (the water temperature is 25°C, the influent flow rate is 5m3 / h, the water quality COD is 86mg / L, and the pH value is 7.6. The total removal rate of COD after activated carbon adsorption is 84.8 %, the total removal rate of COD after A / O treatment is 99.5%.

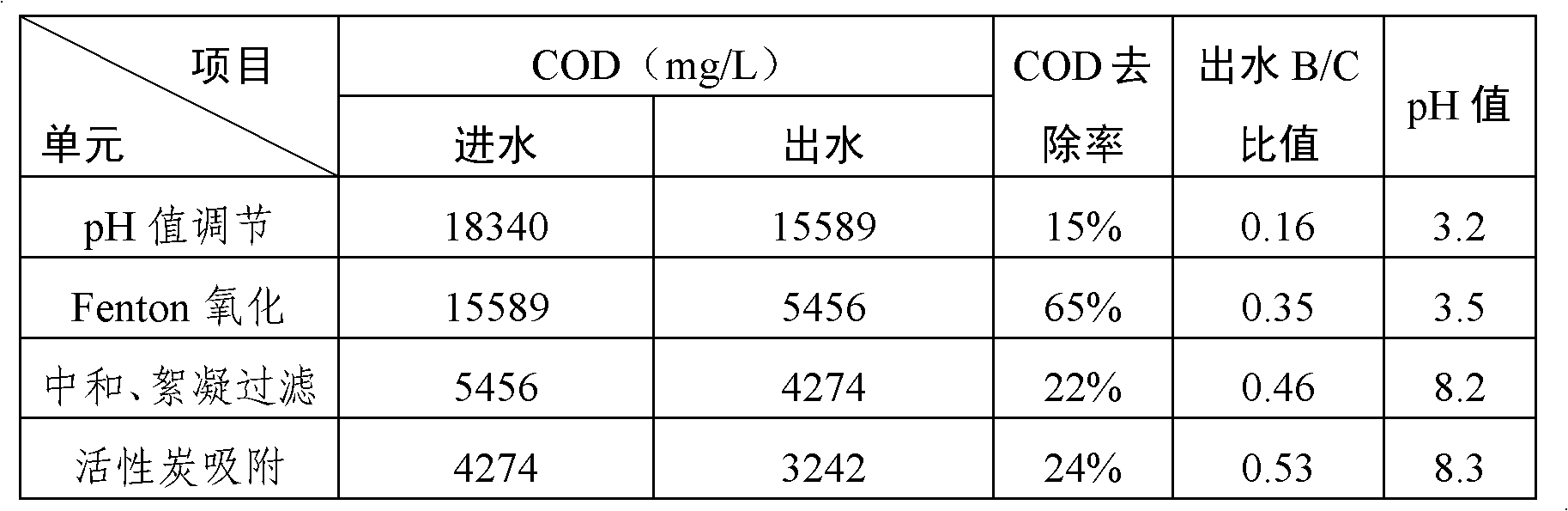

[0054] The wastewater quality indicators at each stage are as follows:

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com