A kind of industrial wastewater purification agent and preparation method thereof

A technology for industrial wastewater and purifying agent, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as poor adsorption stability of suspended solids, limited pore size and specific surface area of purifying agents, secondary pollution, etc. Achieve good coagulation effect, significant degreasing and decolorization effect, and COD reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

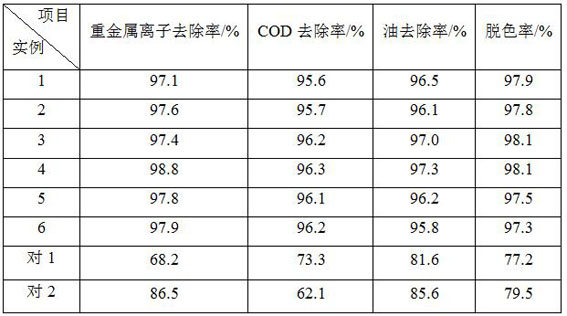

Examples

Embodiment 1

[0026] A kind of industrial waste water purification agent, is made of the raw material of following parts by weight:

[0027] 20 parts of modified attapulgite clay, 20 parts of polyaluminum chloride, 10 parts of chlorine dioxide, 7 parts of aluminum iron silicate, 10 parts of polyacrylamide, 15 parts of alkylphenol polyoxyethylene ether, 5 parts of sodium carbonate, hydrogen 5 parts of calcium oxide.

[0028] The preparation method of described modified attapulgite clay comprises the following steps:

[0029] (1) Attapulgite clay, modified Fe 3 o 4 Granules and sodium alginate placed in nitric acid solution, attapulgite clay, modified Fe 3 o 4 The dosage ratio of granules, sodium alginate and nitric acid solution is 10g: 0.02g: 0.6g: 80mL, and the power is 300W at room temperature, sonication for 40min, followed by filtration, drying and grinding to obtain mixed powder;

[0030] The specific surface area of the attapulgite clay is 50m 2 / g; The concentration of descri...

Embodiment 2

[0035] A kind of industrial waste water purification agent, is made of the raw material of following parts by weight:

[0036] 22 parts of modified attapulgite clay, 22 parts of polyaluminum chloride, 12 parts of chlorine dioxide, 8 parts of aluminum iron silicate, 11 parts of polyacrylamide, 18 parts of alkylphenol polyoxyethylene ether, 6 parts of sodium carbonate, hydrogen 6 parts of calcium oxide.

[0037] The preparation method of described modified attapulgite clay comprises the following steps:

[0038] (1) Attapulgite clay, modified Fe 3 o 4Granules and sodium alginate placed in nitric acid solution, attapulgite clay, modified Fe 3 o 4 The dosage ratio of granules, sodium alginate and nitric acid solution is 10g: 0.03g: 0.7g: 90mL, the power is 400W ultrasonic treatment for 30min at room temperature, followed by filtration, drying and grinding to obtain mixed powder;

[0039] The specific surface area of the attapulgite clay is 60m 2 / g; The concentration of de...

Embodiment 3

[0044] A kind of industrial waste water purification agent, is made of the raw material of following parts by weight:

[0045] 24 parts of modified attapulgite clay, 25 parts of polyaluminum chloride, 14 parts of chlorine dioxide, 9 parts of aluminum iron silicate, 13 parts of polyacrylamide, 20 parts of alkylphenol polyoxyethylene ether, 7 parts of sodium carbonate, hydrogen 9 parts of calcium oxide.

[0046] The preparation method of described modified attapulgite clay comprises the following steps:

[0047] (1) Attapulgite clay, modified Fe 3 o 4 Granules and sodium alginate placed in nitric acid solution, attapulgite clay, modified Fe 3 o 4 The dosage ratio of granules, sodium alginate and nitric acid solution is 10g: 0.04g: 0.8g: 100mL, the power is 500W ultrasonic treatment for 30min at room temperature, followed by filtration, drying and grinding to obtain mixed powder;

[0048] The specific surface area of the attapulgite clay is 60m 2 / g; The concentration of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com