Circular processing method of stainless steel acid washing waste liquid

A technology of pickling waste liquid and recycling treatment, which is applied in metallurgical wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., and can solve problems such as poor economy, heavy environmental burden, and high cost of NaOH lye. To achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

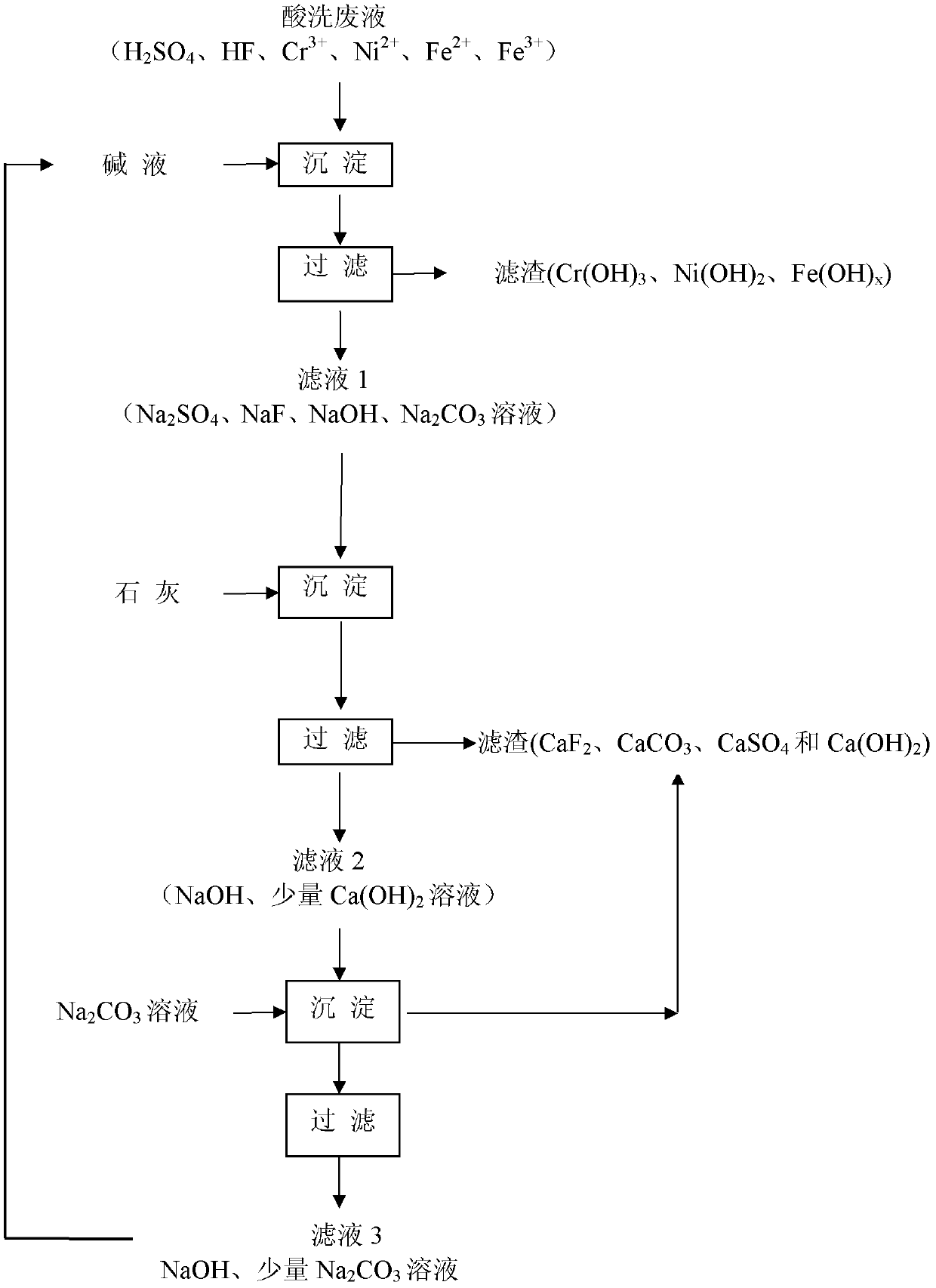

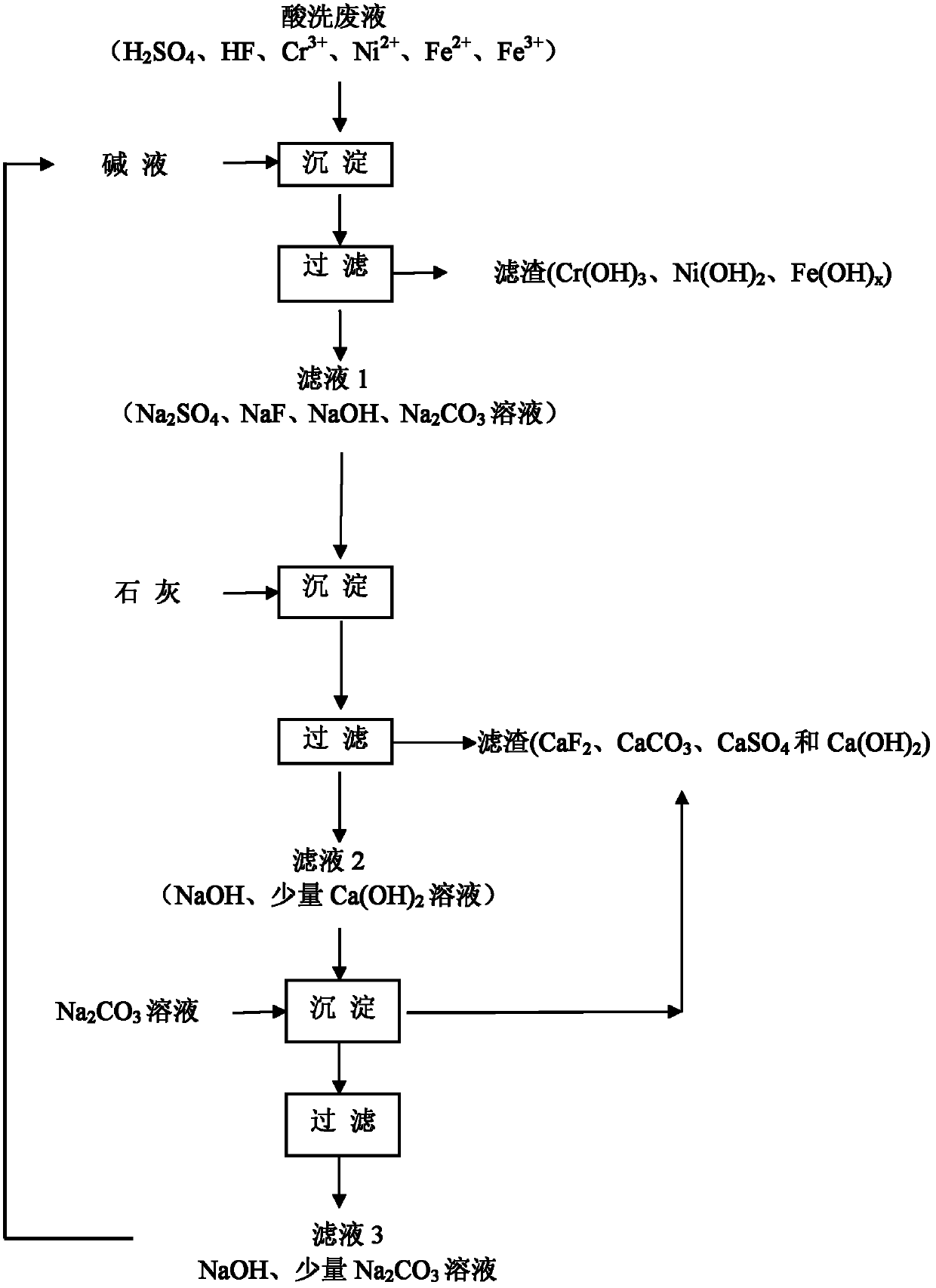

Method used

Image

Examples

Embodiment 1

[0022] Using lye as NaOH and Na 2 CO 3 Add the mixed solution of stainless steel pickling waste liquid to neutralize and precipitate, wherein the gram equivalent of NaOH is Cr 3+ 、Ni 2+ , Fe 2+ and Fe 3+ 1.1 times of the sum of the gram equivalents, and the pH value is adjusted to be 7. metal ion and OH - After precipitation, it was filtered and dried to obtain Cr(OH) 3 , Ni(OH) 2 , Fe(OH) x Metallurgical raw materials that can be recycled and reused. To the filtrate 1, add gram equivalents of F - , CO 3 2- and SO 4 2- Lime with 1.1 times the sum of gram equivalents has a pH value of 8. F in filtrate 1 - , CO 3 2- and SO 4 2- with Ca 2+ CaF was obtained by precipitation filtration 2 , CaCO 3 and CaSO 4 . Add gram equivalents to the filtrate 2 again and be Ca(OH) 2 Na with 1.1 times the gram equivalent 2 CO 3 , the Ca(OH) 2 converted to CaCO 3 Precipitated, filtered to obtain CaCO 3 and containing NaOH, Na 2 CO 3 Filtrate 3. The filtrate 3 is di...

Embodiment 2

[0024] Using lye as NaOH and Na 2 CO 3 Add the mixed solution of stainless steel pickling waste liquid to neutralize and precipitate, wherein the gram equivalent of NaOH is Cr 3+ 、Ni 2+ , Fe 2+ and Fe 3+ 1.5 times of the sum of the gram equivalents, and the pH value is adjusted to 9.5. metal ion and OH - After precipitation, it was filtered and dried to obtain Cr(OH) 3 , Ni(OH) 2 , Fe(OH) x Metallurgical raw materials that can be recycled and reused. To the filtrate 1, add gram equivalents of F - , CO 3 2- and SO 4 2- Lime with 1.5 times the sum of gram equivalents has a pH value of 10. F in filtrate 1 - , CO 3 2- and SO 4 2- with Ca 2+ CaF was obtained by precipitation filtration 2 , CaCO 3 and CaSO 4 . Add gram equivalents to the filtrate 2 again and be Ca(OH) 2 Na with 1.5 times the gram equivalent 2 CO 3 , the Ca(OH) 2 converted to CaCO 3 Precipitated, filtered to obtain CaCO 3 and containing NaOH, Na 2 CO 3 Filtrate 3. The filtrate 3 is di...

Embodiment 3

[0026] Using lye as NaOH and Na 2 CO 3 Add the mixed solution of stainless steel pickling waste liquid to neutralize and precipitate, wherein the gram equivalent of NaOH is Cr 3+ 、Ni 2+ , Fe 2+ and Fe 3+ 1.3 times of the sum of the gram equivalents, and the pH value is adjusted to be 8.5. metal ion and OH - After precipitation, it was filtered and dried to obtain Cr(OH) 3 , Ni(OH) 2 , Fe(OH) x Metallurgical raw materials that can be recycled and reused. To the filtrate 1, add gram equivalents of F - , CO 3 2- and SO 4 2- Lime with 1.3 times the sum of gram equivalents has a pH value of 9. F in filtrate 1 - , CO 3 2- and SO 4 2- with Ca 2+ CaF was obtained by precipitation filtration 2 , CaCO 3 and CaSO 4 . Add gram equivalents to the filtrate 2 again and be Ca(OH) 2 Na with 1.3 times the gram equivalent 2 CO 3 , the Ca(OH) 2 converted to CaCO 3 Precipitated, filtered to obtain CaCO 3 and containing NaOH, Na 2 CO 3 Filtrate 3. The filtrate 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com