Duct grouting slurry with low water-binder ratio and preparation method thereof

A technology for grouting and grouting of ducts, applied in the field of grouting and its preparation, can solve the problems of cement instability affecting project quality, difficulty in meeting standard requirements, affecting construction period, etc., and achieving filling degree and volume stability. Good, the effect of improving the strength guarantee rate and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] According to CN201110433678.5, the preparation method of the high-performance water reducer HL-8010 includes the following steps:

[0025] (1) Add deionized water to the reactor, then add 63 to 82 parts by weight, preferably 70 to 80 parts by weight of ether macromers, prepare it into a solution of 55 to 65% by weight, and heat up to 50 to 80 °C, preferably 60-70 °C, generally 60 °C to completely dissolve;

[0026] (2) After the materials in the reactor are all dissolved, add 2 to 10% of the total monomer weight in the reactor, preferably 4 to 6% aqueous peroxide solution, and the aqueous peroxide solution has a concentration of 2%. hydrogen peroxide;

[0027] (3) 6 to 15 parts by weight, preferably 9 to 11 parts by weight of small molecule monomers and chain transfer agents are formulated with deionized water to form a solution of 20 to 30% by weight as material A, wherein the chain transfer agent is the small molecule 3 to 5% of the weight of molecular monomers;

...

Embodiment 1

[0048] Embodiment 1 (common type tunnel pressure slurry)

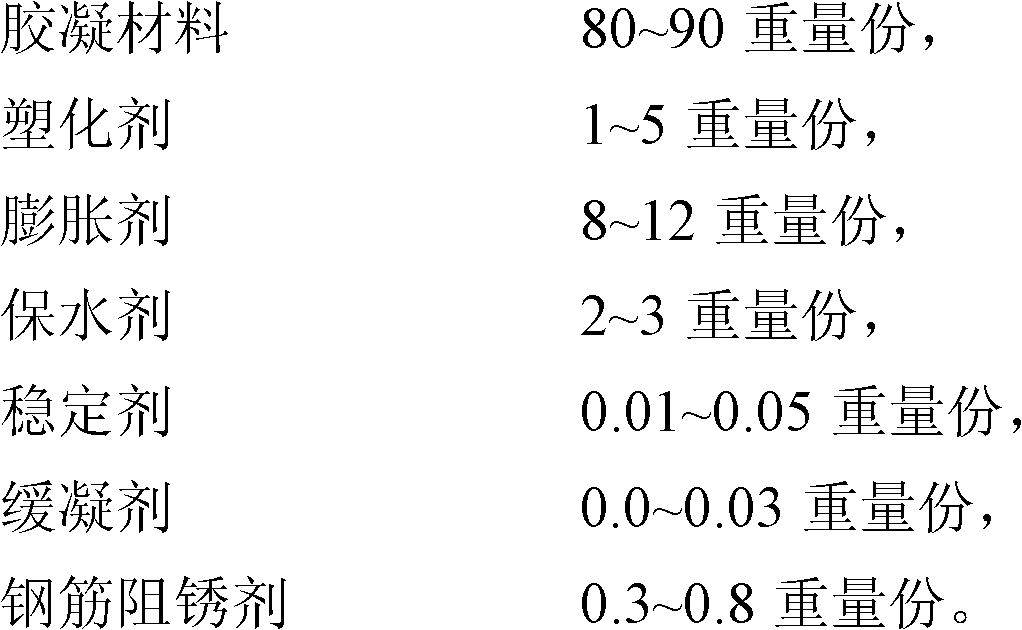

[0049] The parts by weight of each component are as follows:

[0050]

[0051]

Embodiment 2

[0052] Embodiment 2 (plastic-preserving type channel pressure slurry)

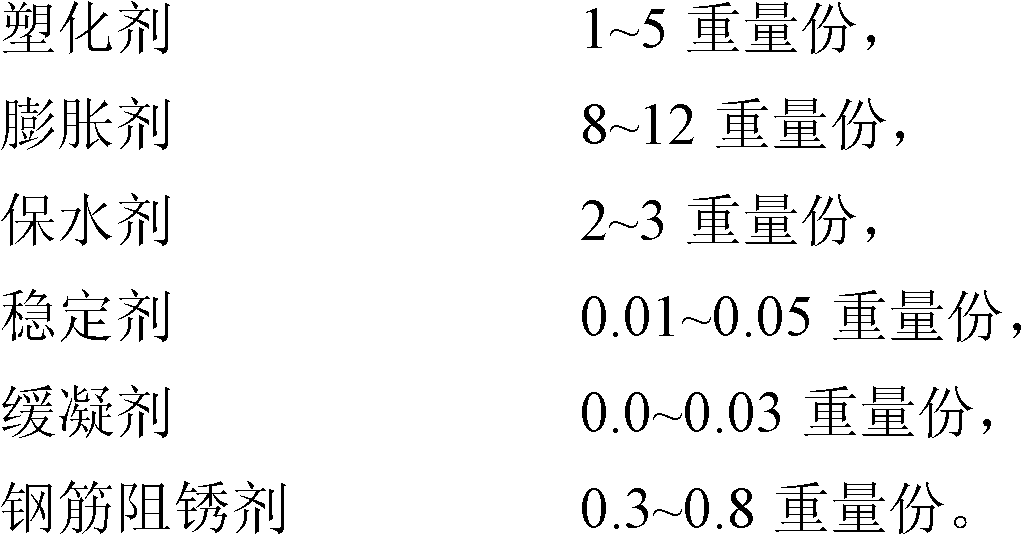

[0053] The parts by weight of each component are as follows:

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com