Surface solid phase graft modified PVDF (Polyvinylidene Fluoride) and preparation method thereof

A technology for modifying and grafting monomers, which is applied in the field of surface solid-phase grafting modified PVDF and its preparation, can solve problems such as environmental pollution, and achieve the effects of solvent-free recovery, low reaction temperature, and expansion of application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

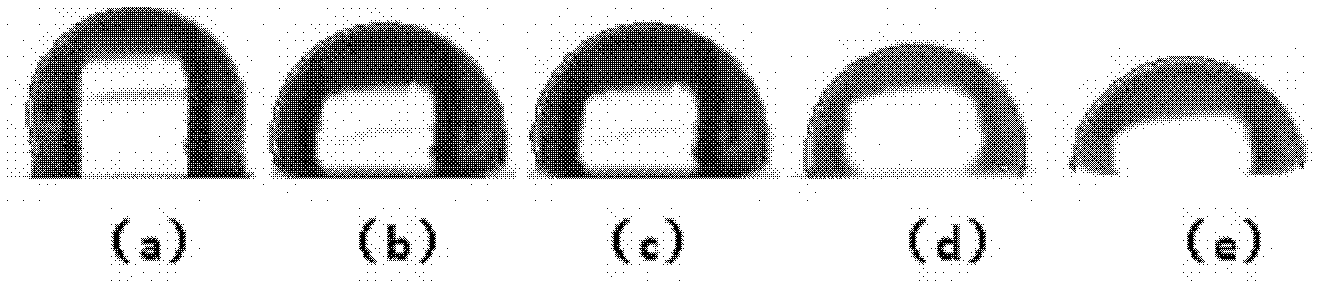

Image

Examples

Embodiment 1

[0036] (1) Weigh 100 parts of PVDF 6008 powder in 1mol / L KOH solution, boil for 1h, cool at room temperature, wash until neutral, and dry at 50°C.

[0037] (2) 100 parts of PVDF powder obtained by step (1) and 10 parts of glycidyl methacrylate are placed in a reactor with a stirring device, and 10 parts of hot dimethylformamide and 20 parts of Acetone, pre-mixed at 100°C for 60 minutes, after the pre-mixing time is over, use a vacuum pump to remove the acetone.

[0038] (3) Under the protection of nitrogen, the temperature was raised to 120°C, and 2 parts of benzoyl peroxide were added to the reaction kettle with a stirring device, and the stirring was stopped after 40 minutes. The product was washed with acetone and then dried in a vacuum oven.

Embodiment 2

[0040] (1) Weigh 100 parts of PVDF 6008 powder in 3mol / L KOH solution, boil for 2 hours, cool at room temperature, wash until neutral, and dry at 50°C.

[0041] (2) 100 parts of PVDF powder obtained by processing step (1) and 5 parts of glycidyl methacrylate and 5 parts of maleic anhydride are placed in a reactor with a stirring device, and the added hot dimethylformamide and 20 parts of acetone, premixed at 120°C for 50 minutes, and after the premixing time was over, the acetone was extracted with a vacuum pump.

[0042] (3) Under the protection of nitrogen, heat up to 120°C, add 2 parts of benzoyl peroxide into the reaction kettle with a stirring device, stop stirring after 60min, and put the product in a vacuum drying oven to dry after being washed with acetone.

Embodiment 3

[0044](1) Weigh 100 parts of PVDF 6008 powder in 1mol / L NaOH solution, boil for 2 hours, cool at room temperature, wash until neutral, and dry at 60°C.

[0045] (2) 100 parts of PVDF powders and 10 parts of maleic anhydride obtained by step (1) are placed in the reactor with stirring device, add 20 parts of hot dimethylformamide and 40 parts of acetone, Pre-mix at 80°C for 50 minutes. After the pre-mixing time is over, use a vacuum pump to remove the acetone.

[0046] (3) Under the protection of nitrogen, heat up to 120°C, add 2 parts of lauryl peroxide into the reaction kettle with a stirring device, stop stirring after 60 minutes, wash the product with acetone and put it in a vacuum drying oven to dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com