Preparation method of nano cellulose composite film

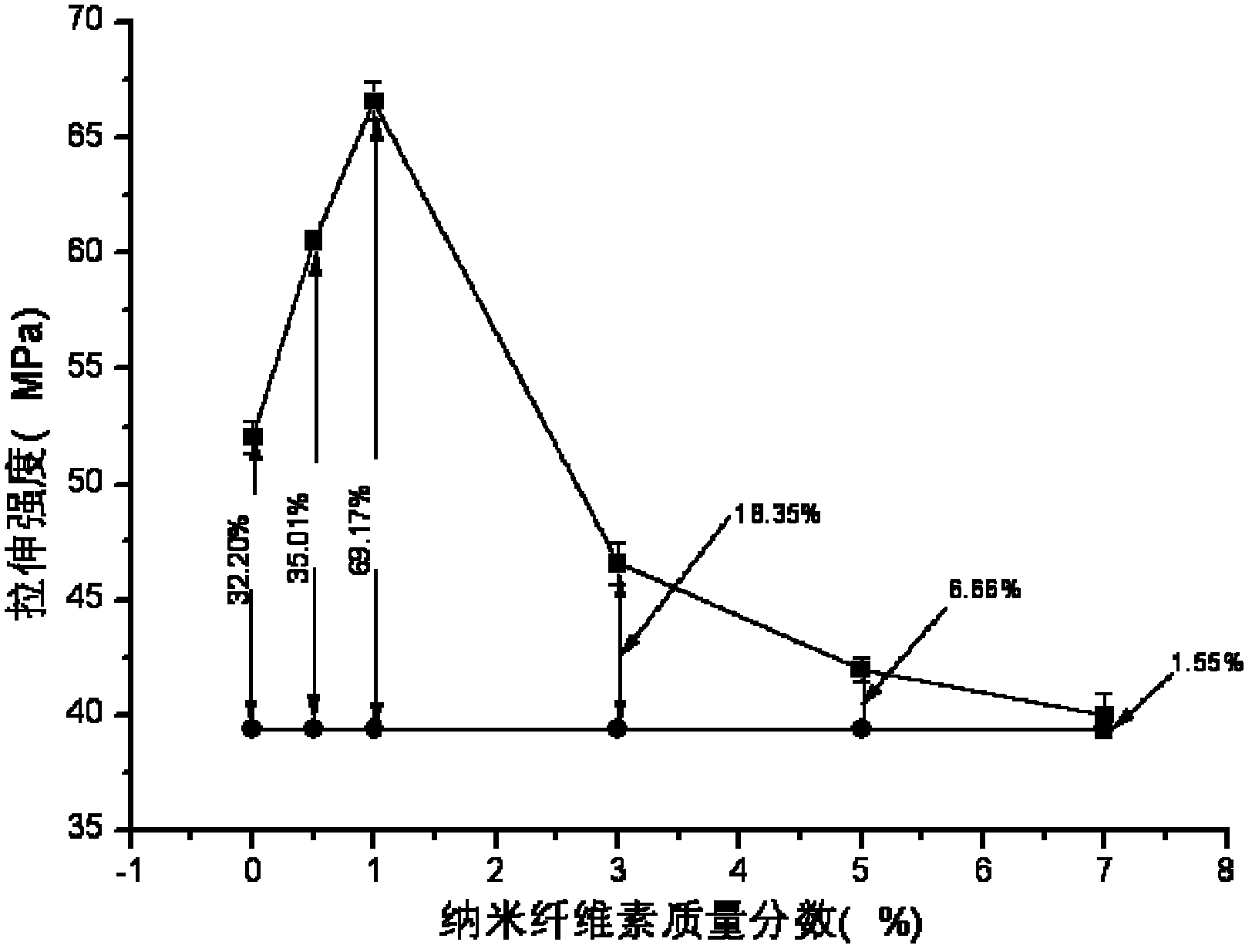

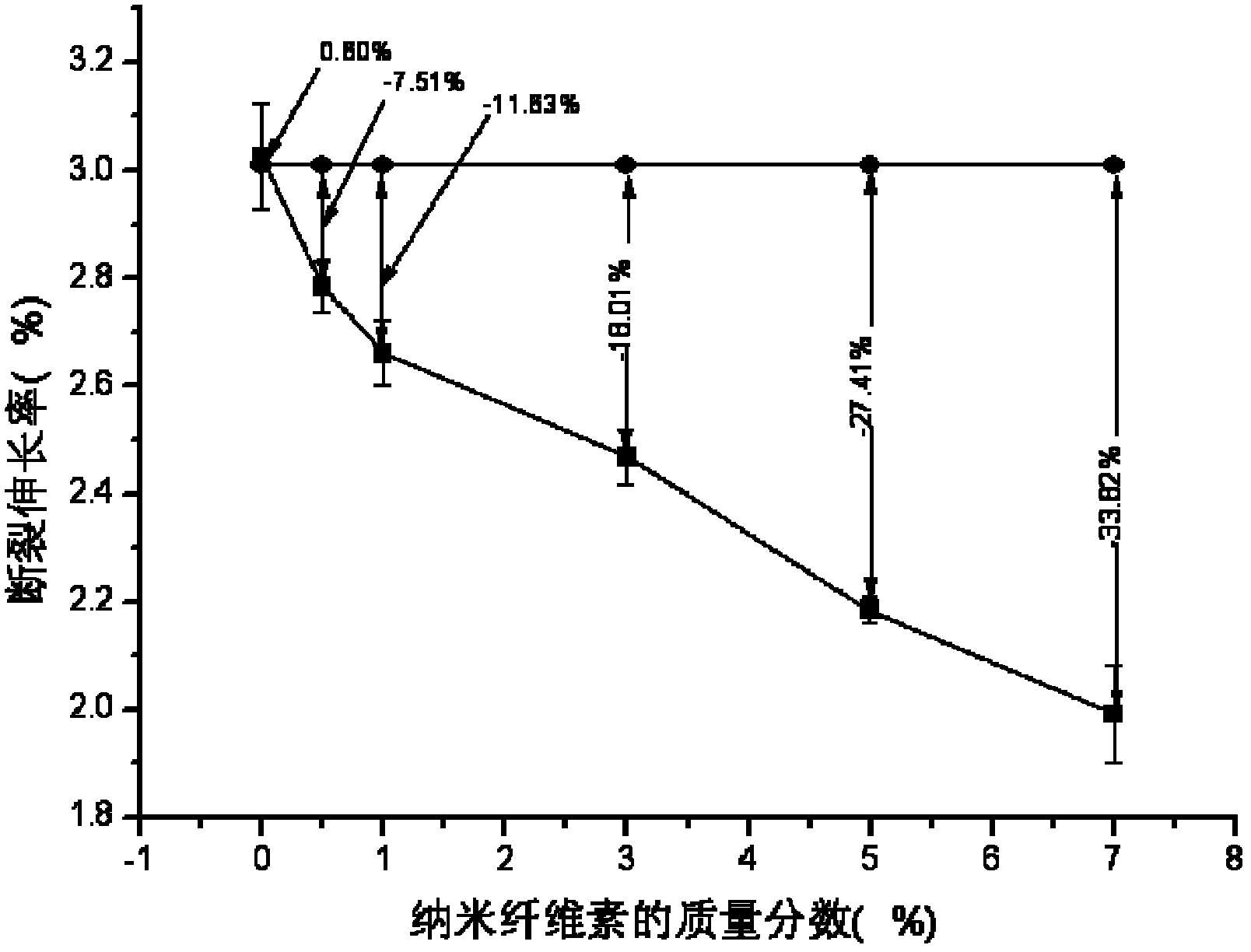

A technology of nanocellulose and composite film, which is applied in the field of composite film preparation, can solve the problems of low tensile strength of film materials, and achieve the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

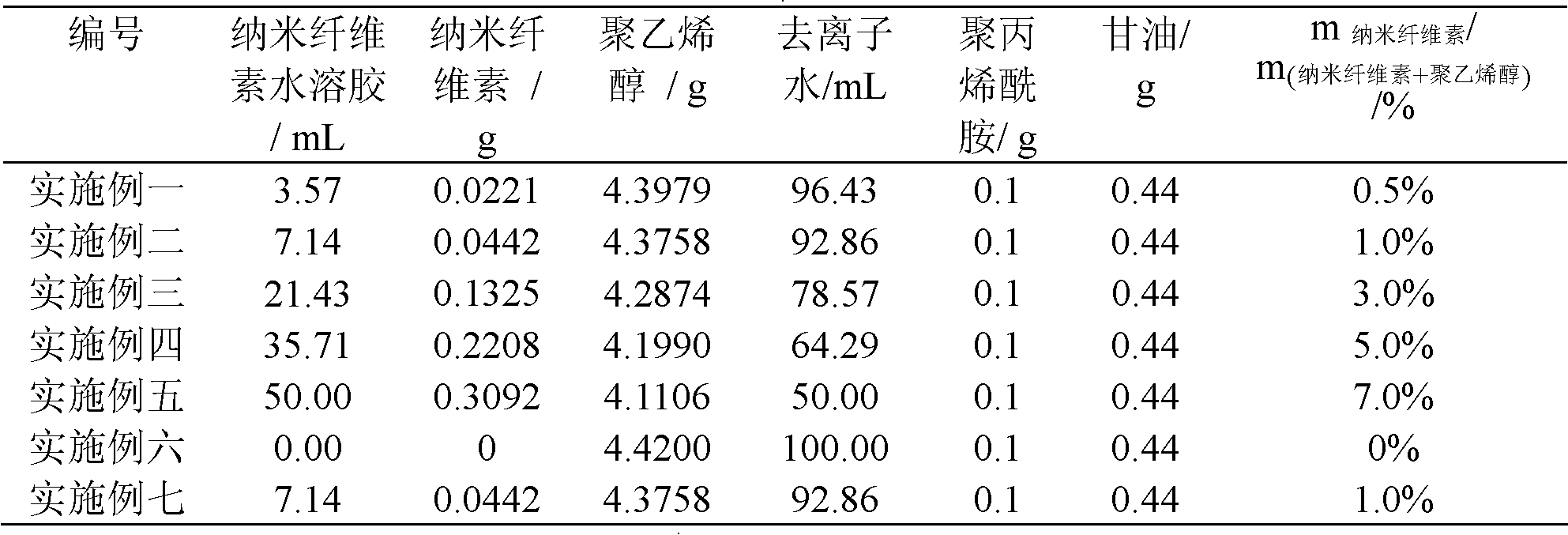

[0013] Specific embodiment one: the preparation method of a kind of nano-cellulose composite film of this embodiment is carried out according to the following steps:

[0014] 1. Prepare nanocellulose hydrosol: prepare nanocellulose hydrosol by hydrolyzing cellulose with strong acid;

[0015] 2. Preparation of nanocellulose film-forming solution: Weigh polyvinyl alcohol, polyacrylamide, glycerin, nanocellulose hydrosol and deionized water prepared in step 1 and mix them to obtain a mixed solution, and mix the mixed solution at 85-95°C Stir in a water bath for 2 to 4 hours, then ultrasonically treat for 5 to 15 minutes, and then vacuum defoam for 5 to 15 minutes to obtain a nanocellulose film-forming solution; wherein, polyvinyl alcohol: nanocellulose: polyacrylamide: glycerin: deionized water The parts by weight ratio is (30~60):(0.12~4.8):(0.5~1.5):(3~6):(900~1100).

[0016] 3. Preparation of nano-cellulose composite film: the film-forming liquid obtained in step 2 is scraped...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the cellulose described in Step 1 is microcrystalline cellulose, reed pulp, eucalyptus pulp, bamboo pulp or straw. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: in step 1, the stirring speed is 500-700 r / min. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com