Flame retardant for polyurethane foam, composition for polyurethane foam, polyurethane foam and preparation method of modified polyurethane foam

A polyurethane foam and a technology for polyurethane foam are applied in the fields of flame retardants for polyurethane foams, compositions for polyurethane foams, polyurethane foams and modified polyurethane foams, and can solve the problem that halogen-containing systems cannot be completely removed. Phosphate impurities, insufficient prevention of fogging, etc., to achieve the effect of improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0126] Although the present invention will be described in more detail based on examples, the present invention is not limited to these examples. In addition, in the following examples and comparative examples, unless otherwise indicated, "%" means "mass %".

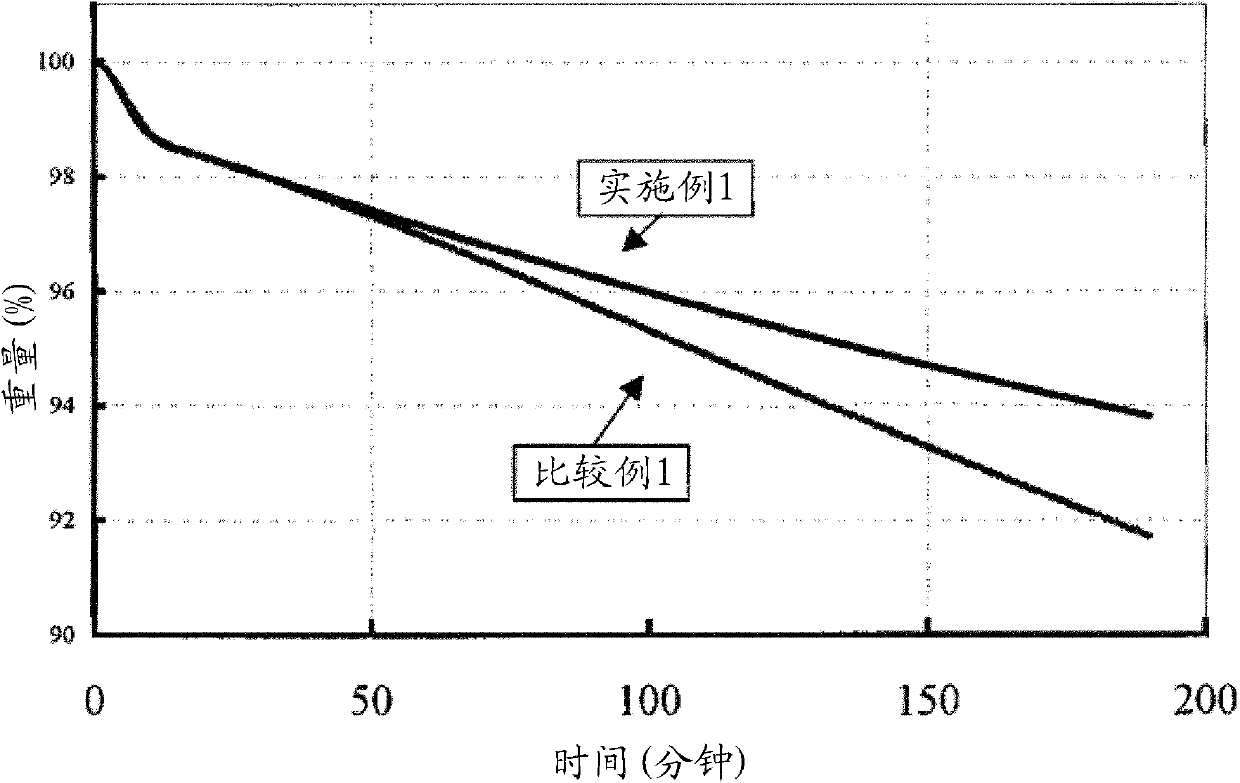

[0127] (Evaluation of Thermal Stability)

[0128] Put a 10 mg sample in TG-DTA EXSTAR 6300 manufactured by SII Co., Ltd., and raise the temperature to 130°C at a rate of 5°C / min in an air flow of 200ml / min (when starting in an atmosphere of 30°C It took 20 minutes to reach 130° C.), kept at 130° C. for 160 minutes (180 minutes in total), and measured the weight loss over time by thermogravimetric analysis (TGA), thereby evaluating the thermal stability. A sample with a large weight loss indicates poor thermal stability.

[0129] (Evaluation of foamability of polyurethane foam)

[0130] Using the following method for producing flame-retardant polyurethane foam, mix polyols, silicone oil, tin-based catalysts, amine-based ...

Embodiment 1

[0144] (Preparation of flame retardant for polyurethane foam and evaluation of thermal stability)

[0145] In 100 parts by mass of diethylene glycol chloropropyl phosphate and its oligomer mixture (DECPP), add 0.1 part by mass of bis(2,4-di-tert-butylphenyl) pentaerythritol diethylene After phosphate ester, mixing is carried out while heating. Thermal stability was evaluated by measuring the decomposition weight loss over time of the obtained transparent liquid flame retardant composition by thermogravimetric analysis. The results are shown in figure 1 middle.

Embodiment 2

[0150] (Preparation of Flame Retardant 1 and Production of Polyurethane Foam)

[0151] To 100 parts by mass of DECPP, 0.1 part by mass of bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite was added, and it mixed while heating at 70 degreeC. Thus, a transparent liquid flame retardant composition (flame retardant 1) was obtained. Using the flame retardant 1, the composition for polyurethane foam was prepared in the compounding ratio shown in Table 1. Using the obtained composition for a polyurethane foam, a polyurethane foam was produced according to the method described in the above-mentioned "Method for Producing a Polyurethane Foam". Various evaluations were performed on the obtained foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com