An atomizing disc, a spray drying atomizer and a method for atomizing high-viscosity materials

An atomizing disc and atomizer technology, which is applied in the directions of spray evaporation and liquid droplet granulation, etc., can solve the problems of unsatisfactory atomization effect and wide particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

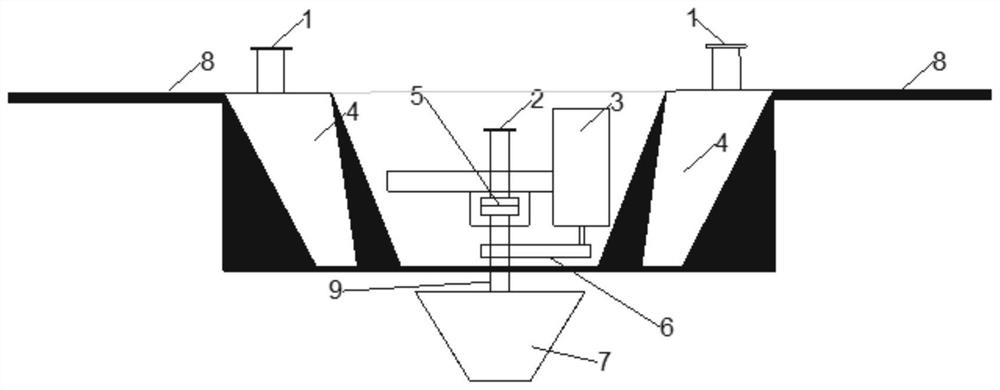

[0029] The following processes combine Figure 1-2 .

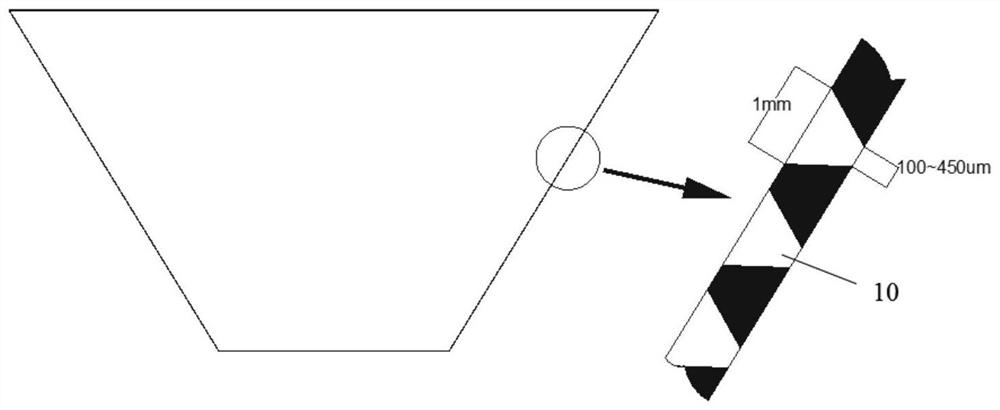

[0030] Weigh 20wt% vitamin A acetate crystals, 10wt% vegetable oil, and 2wt% BHT to prepare an oil phase by dissolving oil; weigh 10wt% white granulated sugar, 38wt% glucose, and 20wt% gelatin plus purified water to prepare an aqueous phase. A stable emulsion was prepared by high-speed shear emulsification and high-pressure homogenization. The viscosity of the emulsion was 400CP. The temperature of the emulsion in the air inlet fluid was 30°C. , the vertical angle of the backflow sheet is 7 degrees, the major diameter of the inverted cone hole is 1mm, and the minor diameter is 100μm) in a spray tower for centrifugal granulation. Then carry out heating and drying with a fixed 70°C hot air fluid in a fixed fluidized bed drier until the moisture content is less than or equal to 5%, cool the material with cold air, and obtain the product.

[0031] The product was tested according to the method shown in Table 1, and the parti...

Embodiment 2

[0034] The following processes combine Figure 1-2 .

[0035] Weigh 20wt% vitamin A acetate crystals, 10wt% vegetable oil, and 2wt% BHT to prepare an oil phase by dissolving oil; weigh 10wt% white granulated sugar, 38wt% glucose, and 20wt% gelatin plus purified water to prepare an aqueous phase. A stable emulsion was prepared by high-speed shear emulsification and high-pressure homogenization. The viscosity of the emulsion was 1500CP. The temperature of the emulsion in the air inlet fluid was 30°C. , the vertical angle of the backflow sheet is 10 degrees, the major diameter of the inverted cone hole is 1 mm, and the minor diameter is 250 μm) in a spray tower for centrifugal granulation. Then carry out heating and drying with a fixed 70°C hot air fluid in a fixed fluidized bed drier until the moisture content is less than or equal to 5%, cool the material with cold air, and obtain the product.

[0036] The product was tested according to the method shown in Table 1, and the p...

Embodiment 3

[0039] The following processes combine Figure 1-2 .

[0040] Weigh 20wt% vitamin A acetate crystals, 10wt% vegetable oil, and 2wt% BHT to prepare an oil phase by dissolving oil; weigh 10wt% white granulated sugar, 38wt% glucose, and 20wt% gelatin plus purified water to prepare an aqueous phase. A stable emulsion was prepared by high-speed shear emulsification and high-pressure homogenization. The viscosity of the emulsion was 2250CP. The temperature of the emulsion in the air inlet fluid was 30°C. , the vertical angle of the backflow sheet is 15 degrees, the major diameter of the inverted cone hole is 1 mm, and the minor diameter is 450 μm) in a spray tower for centrifugal granulation. Then carry out heating and drying with a fixed 70°C hot air fluid in a fixed fluidized bed drier until the moisture content is less than or equal to 5%, cool the material with cold air, and obtain the product.

[0041] The product was tested according to the method shown in Table 1, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com