Manual multi-layer solid wood floor and production process thereof

A technology of solid wood flooring and production technology, applied in the field of architectural decoration, can solve problems such as inconvenient operation, difficulty in controlling moisture content, and increased production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

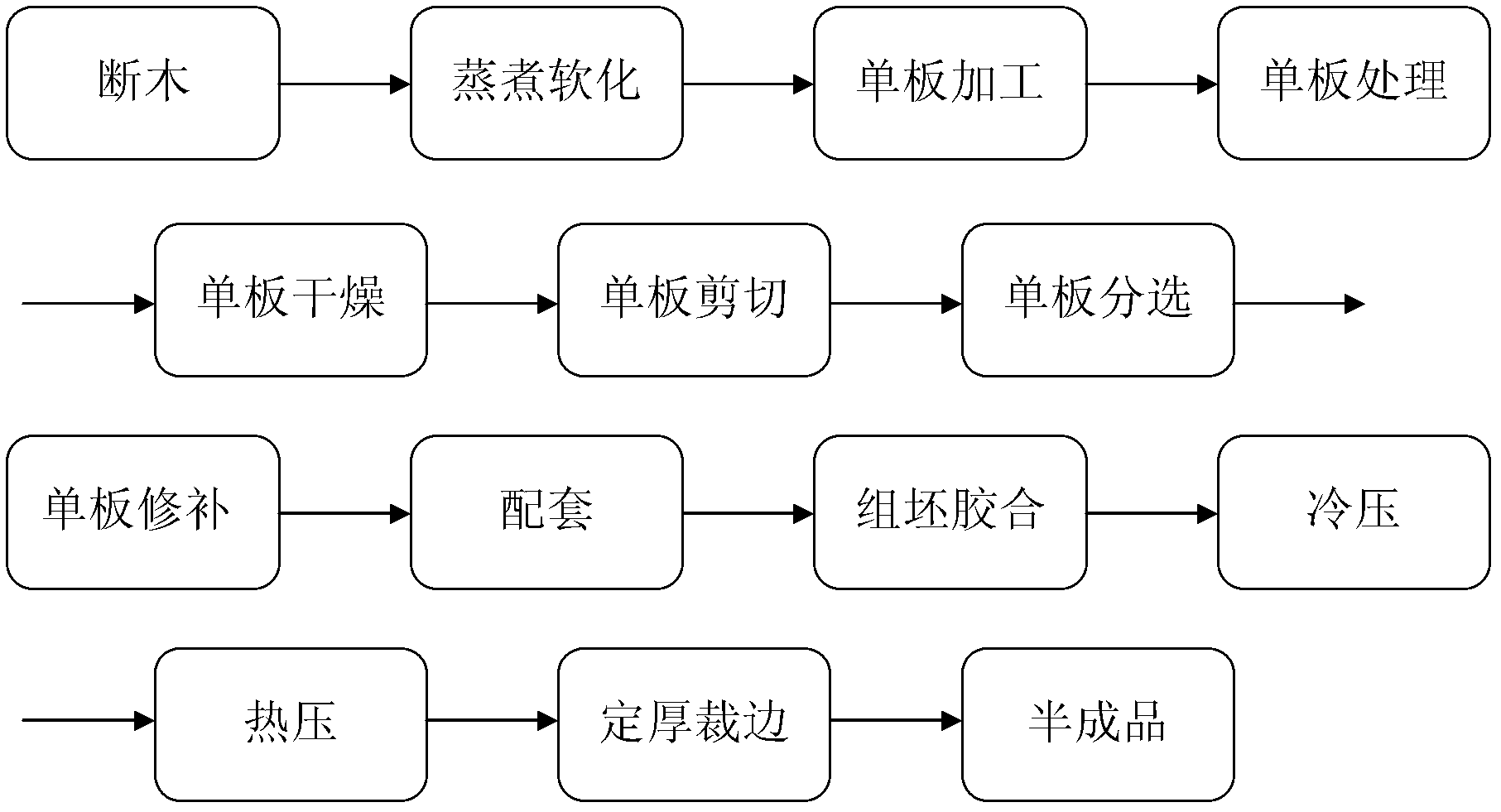

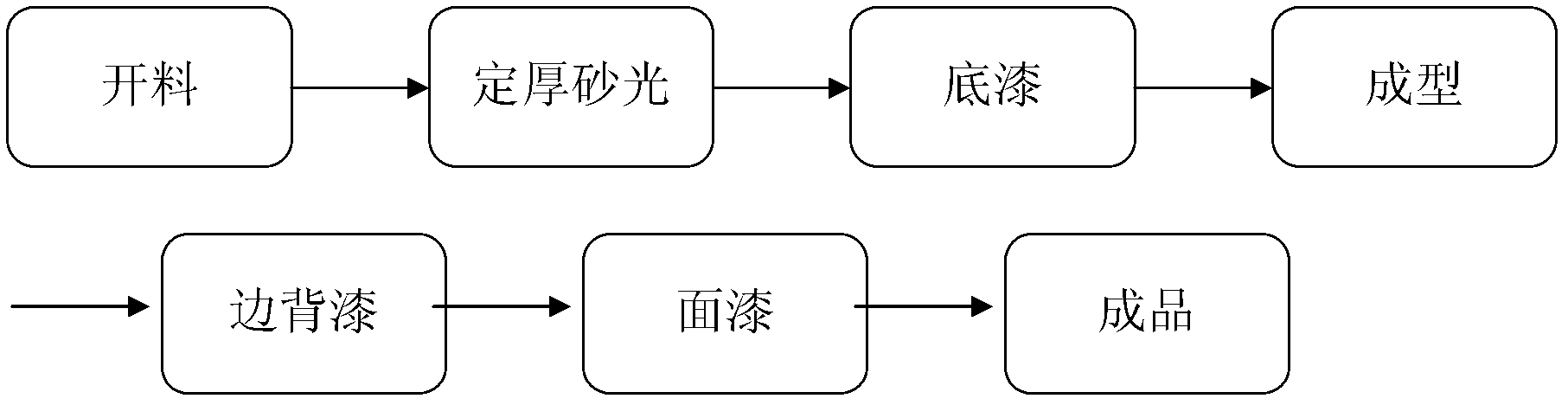

[0052] Take the 5-layer 12mm thick Australian eucalyptus floor as an example. First, cut the eucalyptus logs, and then steam the broken logs. Use clean water to cook for 5-6 days. The temperature is controlled at about 90°C, pay attention to control Heating process. After cooking, the broken wood is peeled to obtain veneers of the required thickness. After the treatment, use a mesh bag dryer for drying treatment, the drying temperature is controlled at 170-190°C, the speed is 0.5-1m / min, and the moisture content of the obtained veneer is controlled between 6%-10%.

[0053] Afterwards, the veneer is cut to the required length and width, sorted, repaired, and then matched, and the next step is the gluing of the blanks. The best preparation ratio of the glue is raw glue: flour: ammonium chloride: Oxalic acid = 130-150kg: 16-19kg: 60-80g: 210-250g, the pH of the glue is 5.5-6.5, the viscosity = 6500-8000cp, the coating amount is double-sided coating, a total of 760-800g / m 2 . T...

Embodiment 2

[0057] Taking the 9-layer 15mm thick Australian eucalyptus floor as an example, first cut the eucalyptus logs, and then steam the broken logs for 6-7 days with clean water. The temperature is controlled at about 90°C, pay attention to control Heating process. After cooking, the broken wood is peeled to obtain veneers of the required thickness. After the treatment, use a mesh bag dryer for drying treatment. The drying temperature is controlled at 120-140°C, the speed is 2-3m / min, and the moisture content of the obtained veneer is controlled between 6%-10%.

[0058] Afterwards, the veneer is cut to the required length and width, sorted, repaired, and then matched, and the next step is the gluing of the blanks. The best preparation ratio of the glue is raw glue: flour: ammonium chloride: Oxalic acid = 110-130kg: 14-17kg: 60-70g: 200-240g, the pH of the glue is 5.5-7, the viscosity = 4000-6000cp, the coating amount is double-sided coating, a total of 600-650g / m 2 . Then carry o...

Embodiment 3

[0062] Take the 9-layer hickory floor with a thickness of 15mm as an example. Firstly, the hickory logs are cut off, and then the cut logs are steamed for 8-9 days with clean water. . After cooking, the broken wood is peeled to obtain veneers of the required thickness. After the treatment, use a mesh bag dryer for drying treatment, the drying temperature is controlled at 150-140°C, the speed is 2-2.5m / min, and the moisture content of the obtained veneer is controlled between 6%-10%.

[0063] Afterwards, the veneer is cut to the required length and width, sorted, repaired, and then matched, and the next step is the gluing of the blanks. The best preparation ratio of the glue is raw glue: flour: ammonium chloride: Oxalic acid = 110-130kg: 15-18kg: 55-65g: 200-220g, the pH of the glue is 5.5-6.5, the viscosity = 5500-7000cp, the coating amount is double-sided coating, a total of 700-800g / m 2 . Then carry out cold pressing, the cold pressing time is 2-3 hours, pressure=14-16MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com