Open forward and inverse cycle coupling triple supply system of electricity, heat and cold based on combustion gas turbine

A gas turbine, electric heating and cooling technology, applied in the direction of non-flammable liquid/gas transportation, combustion methods, mechanical equipment, etc., can solve the problems of high difficulty, large investment, large water consumption, etc., and achieve the effect of ensuring self-balancing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

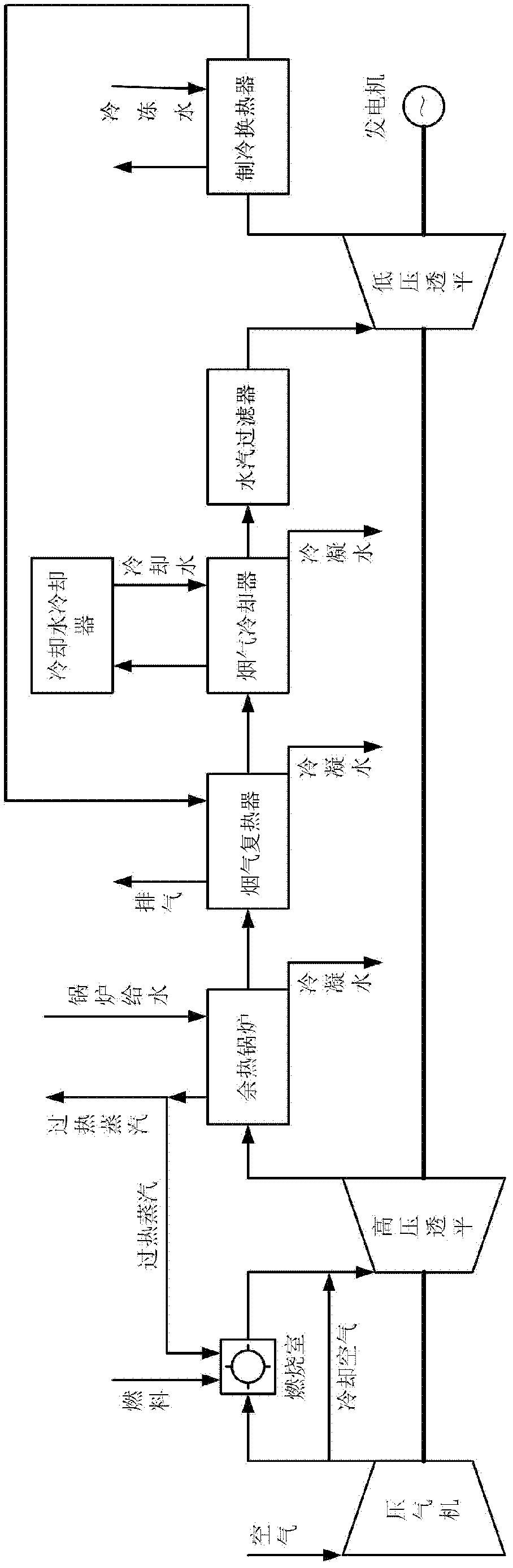

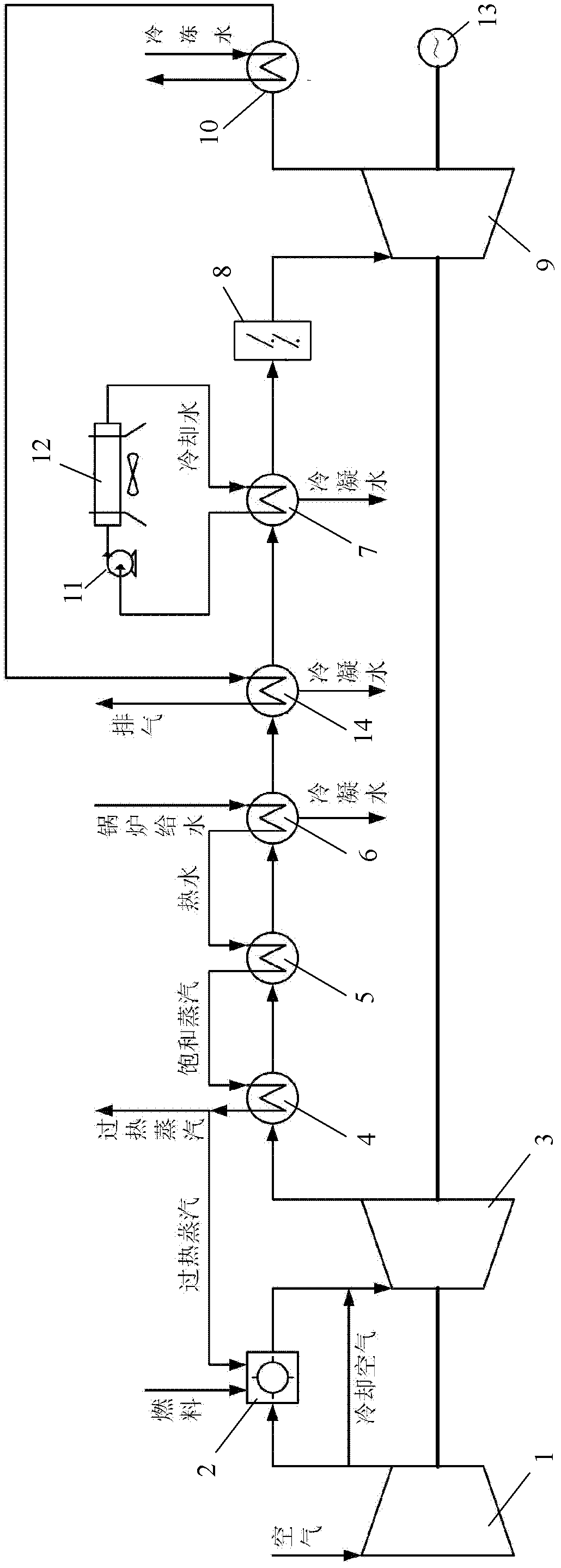

[0023] Such as figure 1 The gas turbine-based open forward and reverse cycle coupled electric heating and cooling triple supply system shown includes compressor 1, combustion chamber 2, high-pressure turbine 3, generator 13, waste heat boiler, flue gas recuperator 14, and flue gas cooler 7. The low-pressure turbine 9 and the refrigeration heat exchanger 10, the compressed air output end of the compressor 1 is connected to the air input end of the combustion chamber 2, the flue gas output end of the combustion chamber 2 is connected to the input end of the high-pressure turbine 3, and the high-pressure The output shaft of turbine 3 is respectively connected with the impeller shaft of compressor 1 and the input shaft of generator 13, and the output shaft of high-pressure turbine 3 simultaneously drives the impeller shaft of compressor 1 and the input shaft of generator 13 to rotate, and the high-pressure turbine The flue gas output end of waste heat boiler 3 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com