Bunker coal level detecting method based on virtual instrument intelligent cameras

A technology of intelligent camera and detection method, which is applied in the direction of instrumentation, engine lubrication, machine/engine, etc., can solve problems affecting the normal operation of coal-fired power plants, difficult maintenance work, and the inability to ensure the stable operation of the coal bunker automatic coal blending system. Achieve considerable economic benefits, safe supply, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

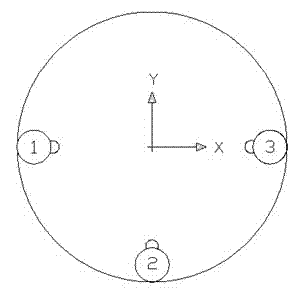

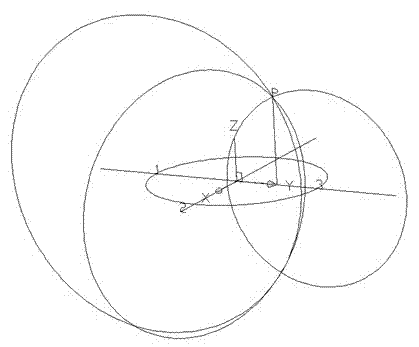

[0025] refer to figure 1 , install the smart camera in three directions of the coal bunker, which are due south, due west, and due east. The three smart cameras are on the same horizontal plane. In the case of weak light and harsh environment, real-time monitoring of coal in the coal bunker From the coal pile image captured by the camera, the depth image matching can be performed to determine the contour line between the coal in the coal bunker and the coal bunker wall and the highest point of the coal pile, which is convenient for sampling the image contour, and does not There are blind spots, which improves the accuracy of observation.

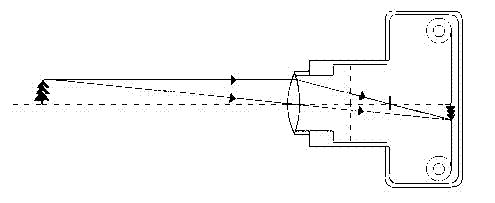

[0026] figure 2 It is a schematic diagram showing the coordinate conversion relationship, and accurate position information is extracted by using the distance measuring device with the smart camera according to the present invention.

[0027] refer to figure 2 According to the coordinate transformation method, take any one of the smart ...

Embodiment approach 2

[0041] Embodiment 3: a=150, b=150, and c=1843.834mm is obtained. Others are the same as Embodiment 1.

Embodiment approach 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com