Natural gas aluminum smelting furnace

A technology of aluminum smelting furnace and natural gas, which is applied to furnaces, charge materials, crucible furnaces, etc., can solve problems such as low energy utilization efficiency, and achieve the effect of improving energy utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

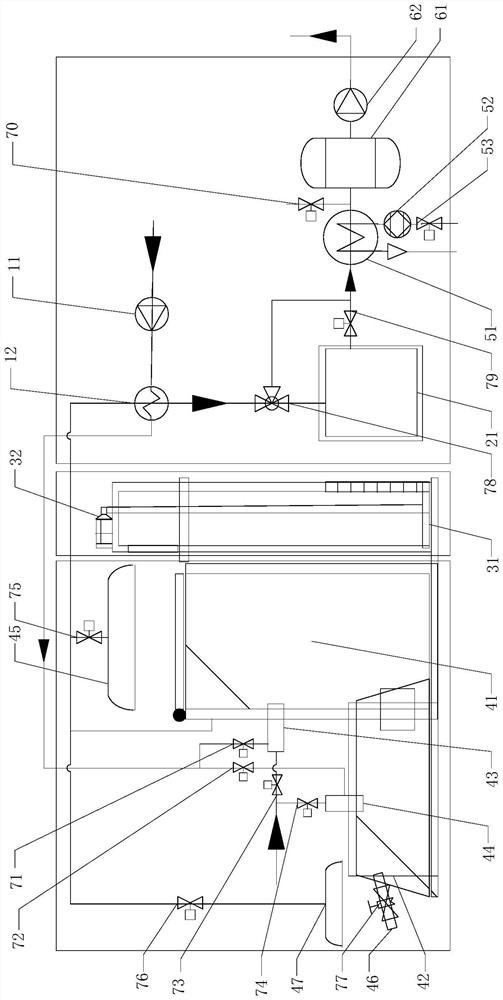

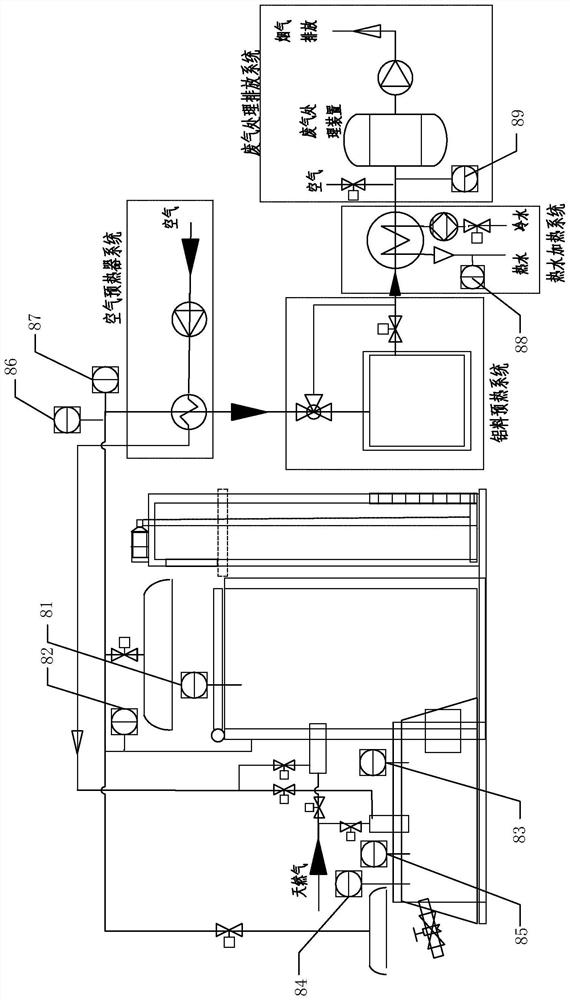

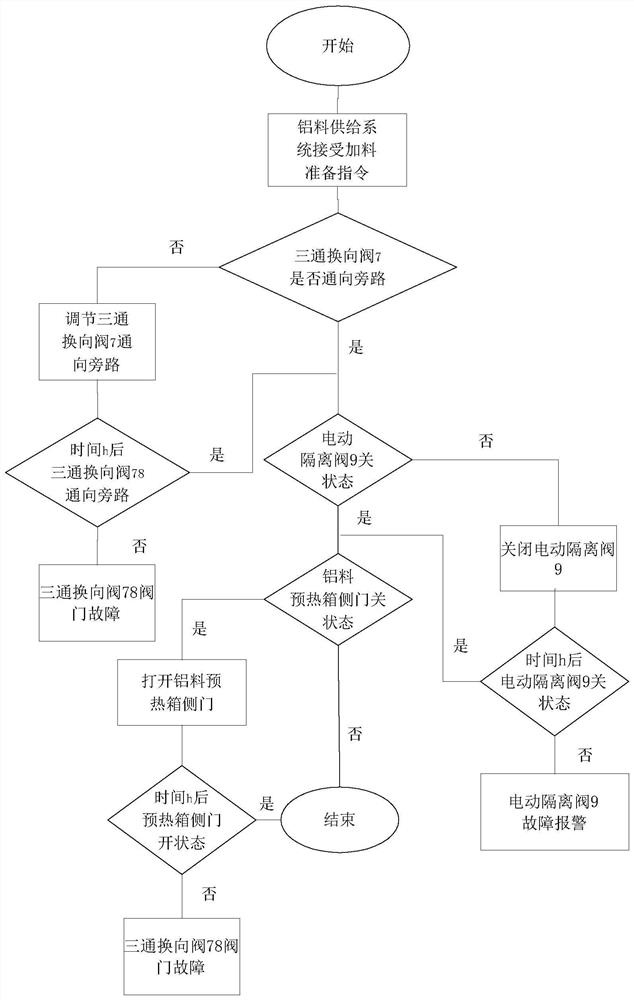

[0063] see Figure 1 to Figure 15 , a natural gas aluminum smelting furnace according to Embodiment 1 of the present invention, said natural gas aluminum smelting furnace comprising:

[0064] Air preheating system, including combustion-supporting blower 11 and air preheater 12;

[0065] natural gas supply system;

[0066] Aluminum material preheating system, including aluminum material preheating box 21;

[0067] Aluminum material supply system, including loading platform 31 and lifting motor 32;

[0068] The liquid aluminum production system includes a connected aluminum material melting chamber 41 and an aluminum liquid heat preservation chamber 42, wherein a melting burner 43 is provided in the aluminum material melting chamber 41, and a heat preservation burner 44 is provided in the aluminum liquid heat preservation chamber 42;

[0069] A hot water heating system, including a hot water heater 51, a water inlet pipeline, a water outlet pipeline, a water supply pump 52 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com