System for measuring thermal performance transiently by using pulsing method or constant current method

A technology of constant current method and pulse method, applied in the system field of transient measurement of thermophysical properties by pulse method or constant current method, can solve the problems of high price, unable to meet the needs of social development, time-consuming and high-consumption measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

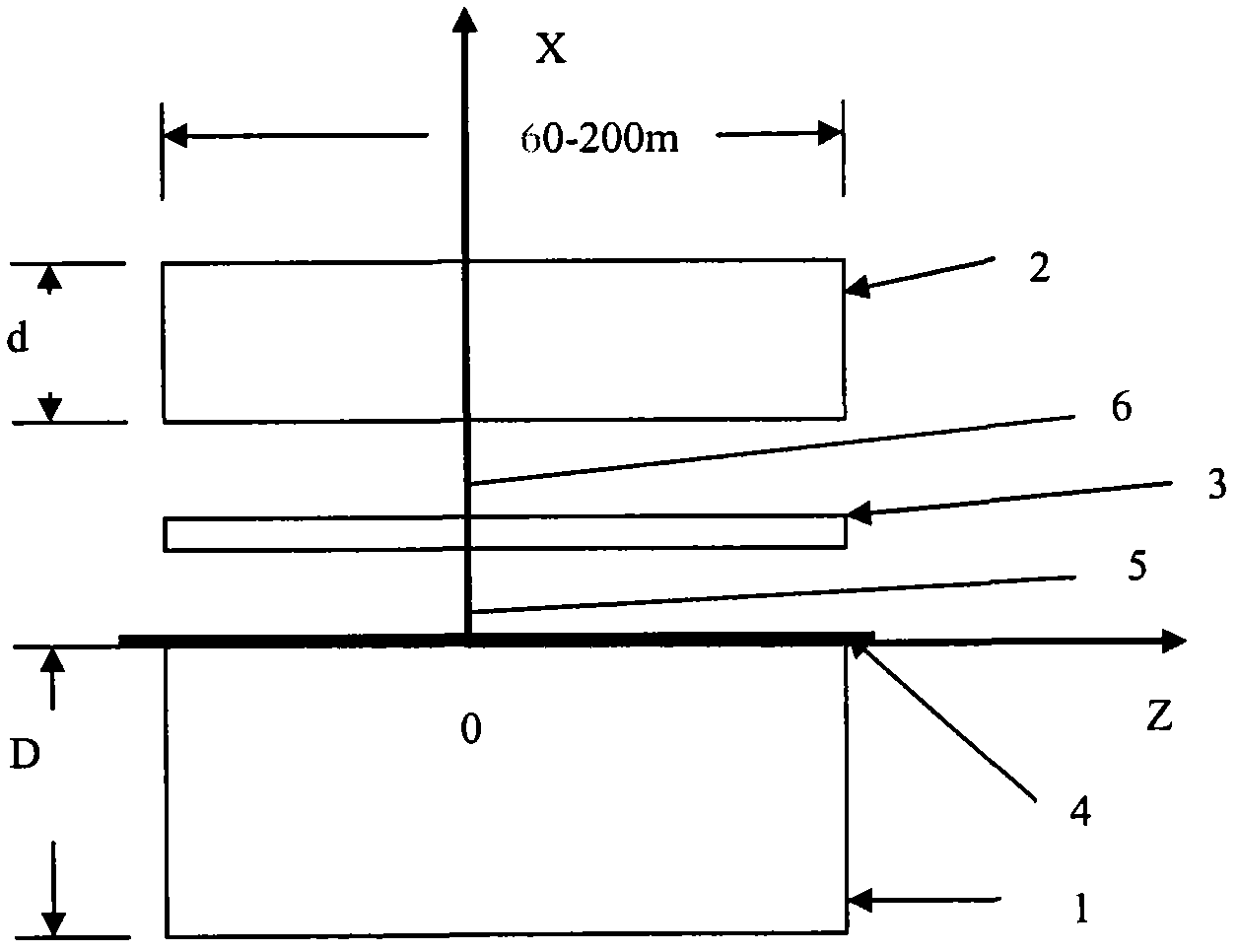

[0041] 1 Specimen and measurement arrangement of one-dimensional semi-infinite heat transfer model

[0042] 1.1 The test piece of the one-dimensional semi-infinite heat transfer model

[0043] refer to figure 1 , the test piece is composed of three flat plates of the same material, the main test piece, the auxiliary test piece 1 and the auxiliary test piece 2, whose length and width are both 60-200 mm. The thickness of the main test piece can vary greatly depending on the density of the material to be tested. For most of the materials to be tested, the value can be taken between 2 and 20mm. If the thickness of the main test piece is xmm, the thickness D of auxiliary test piece 1: D≥3xmm; the thickness d of auxiliary test piece 2: d≥2xmm. When the three test pieces are stacked, the contact surface should be smooth and smooth, and the thermal contact should be good.

[0044] 1.2 Measurement arrangement of one-dimensional semi-infinite heat transfer model

[0045] The three ...

Embodiment 2

[0048] Embodiment 2 Transient Automatic Measurement System

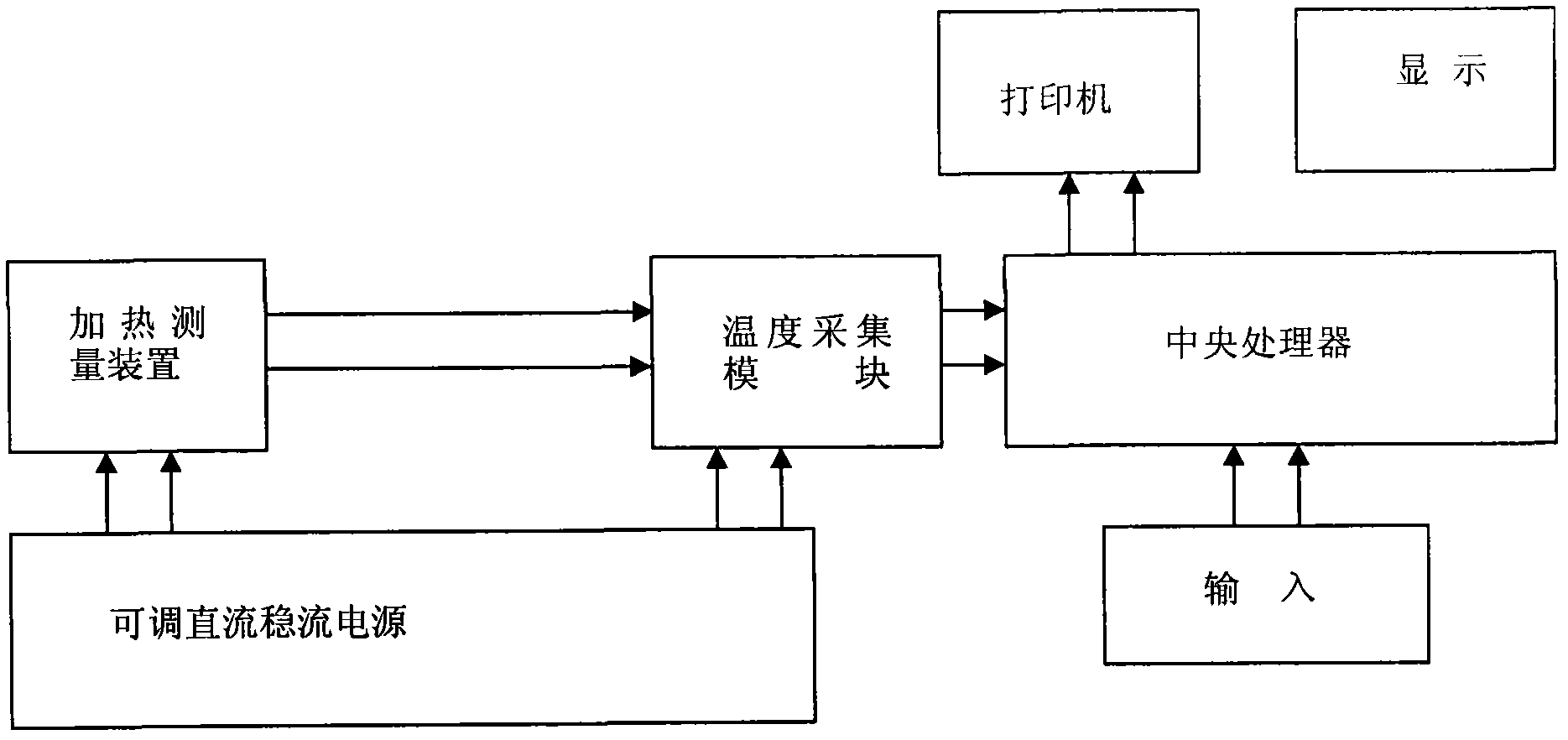

[0049] 2.1 Structural block diagram of the transient automatic measurement system

[0050] Structural block diagram of the thermal and physical property transient automatic measuring device of the present invention, as figure 2As shown, it includes an adjustable DC steady-current power supply, a heating measurement device, a temperature acquisition module, and a central processing unit. The adjustable DC steady-current power supply is used to provide power to the heating measurement device and the temperature acquisition module. The heating measurement device is in accordance with Embodiment 1 Part 1.2 of the layout, the temperature acquisition module is used to collect the temperature-time curve of the cold surface and the hot surface, and the central processor is used to obtain the thermal physical properties of the material through calculation and processing according to the temperature-time curve. The relevant d...

Embodiment 3

[0052] 3 pulse method and constant current method

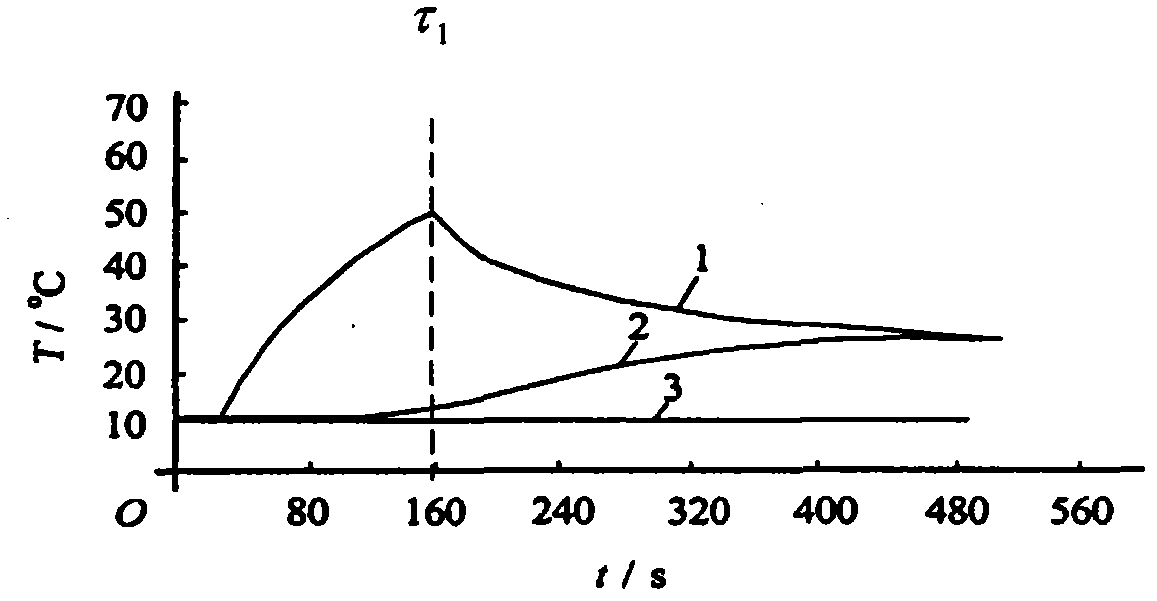

[0053] 3.1 Temperature-time curve of pulse heating measurement

[0054] according to figure 1 Arrange the heating measuring device, when pulse heating, the measured temperature-time curve is as follows image 3 shown. image 3 Middle: Curve 1 is the T(0, t)-t curve of the hot surface; Curve 2 is the T(x, t)-t curve of the cold surface; Curve 3 is the ambient temperature curve. During the short measurement process, the ambient temperature Usually stays the same.

[0055] 3.2 Pulse method and constant current method

[0056] exist image 3 , with the dotted line τ 1 The following measurement data, the method of calculating the thermophysical properties of the material, is called the pulse method; use the dotted line τ 1 The previous measurement data is a method for calculating the thermophysical properties of materials, because the heat flux intensity passing through the contact interface between the planar heat source a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com