Heating cable

A heating cable and heating conductor technology, applied in the direction of heating element material, heating element shape, etc., can solve the problems of low heat utilization rate, unfavorable large-area laying, inconvenient installation, etc., and achieve improved safety factor, good conductivity, The effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

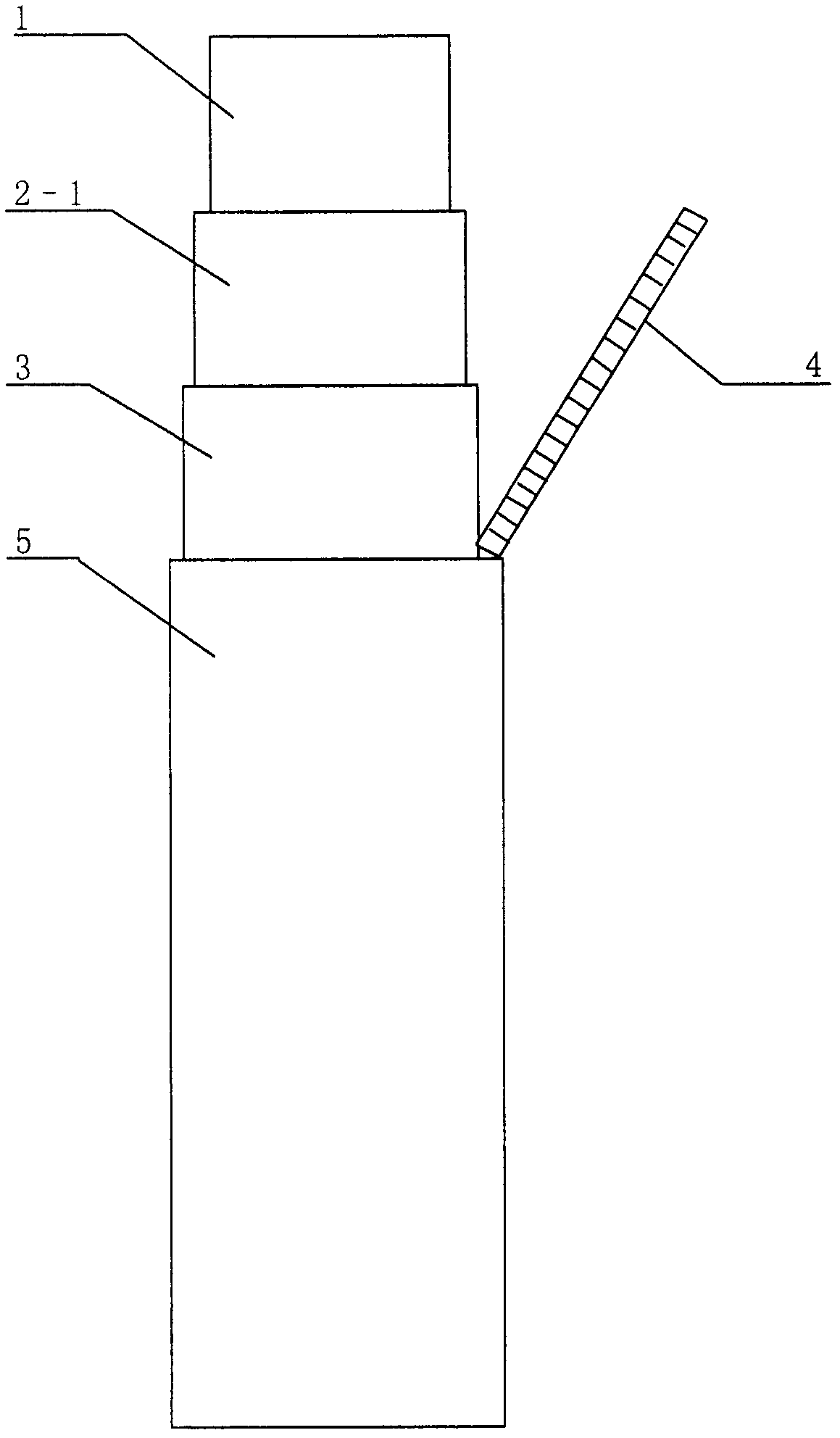

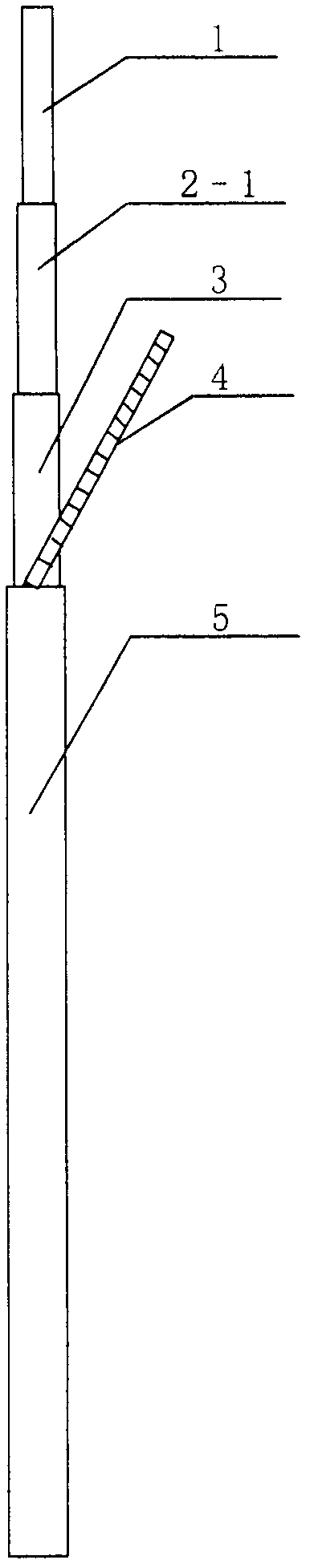

[0037] Such as figure 1 , figure 2 As shown, a heating cable with a drain wire and a shielding layer.

[0038] An ultra-thin copper-nickel alloy (CuNi10 or CuNi14) strip is used as a heating conductor 1, an insulating layer 2-1, a shielding layer 3, a drain wire 4, and an outer sheath 5.

[0039] Width mm×thickness mm=(4~25)×(0.025~0.6) CuNi10 or CuNi14 alloy strips are respectively used as heating conductor 1, and polyvinyl chloride, cross-linked polyethylene or fluoroplastic or silicon with a thickness of 0.3~0.5mm are used. Rubber plastic is used as the inner insulation layer 2-1, and aluminum-plastic composite film with a thickness of 0.01-0.05mm is used as the shielding layer 3, and the thickness is 0.2mm 2 -1.0mm 2 The copper stranded wire is used as the drain wire 4, and the outer sheath 5 is made of polyvinyl chloride plastic, fluoroplastic or silicon rubber plastic with a thickness of 0.3-0.5 mm.

[0040] The production steps are:

[0041] 1) Glue. Apply silica...

Embodiment 2

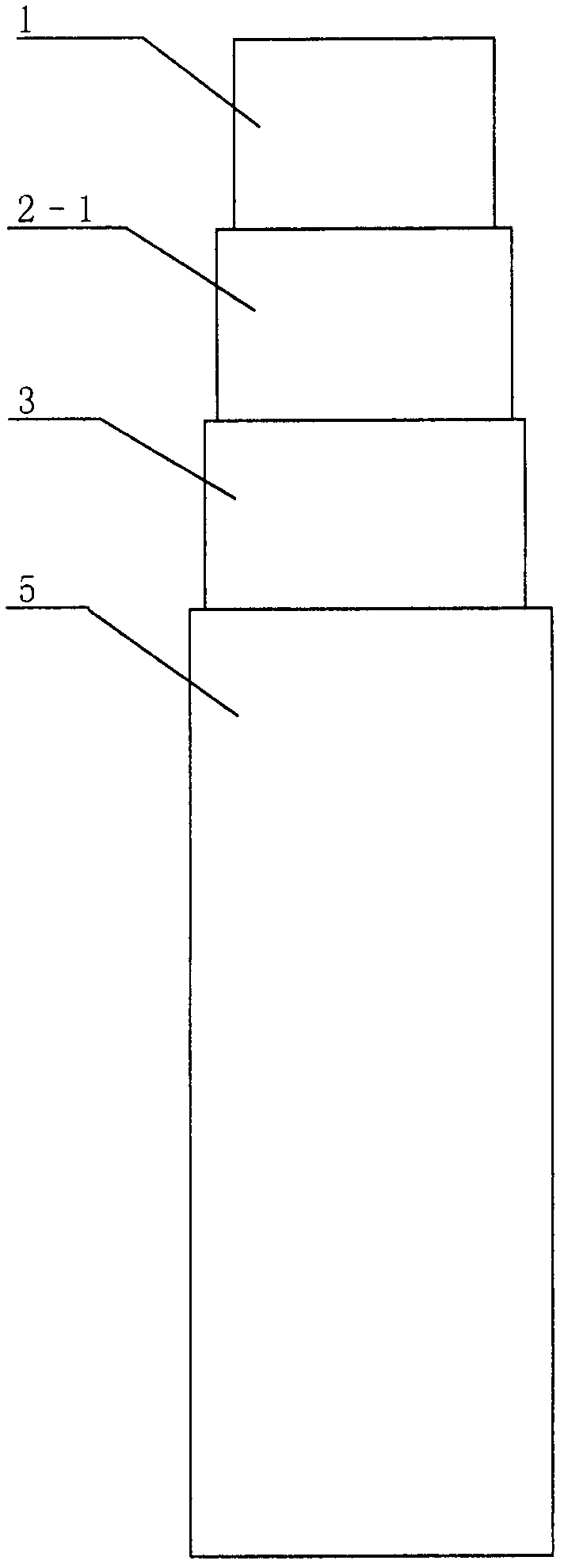

[0051] Such as image 3 , Figure 4 Shown, with a no drain wire, shielded, heating cable.

[0052] An ultra-thin copper-nickel alloy (CuNi10 or CuNi14) strip is used as a heating conductor 1, an insulating layer 2-1, a shielding layer 3, and an outer sheathing layer 5.

[0053]Width mm×thickness mm=(4~25)×(0.025~0.6) CuNi10 or CuNi14 alloy strips are respectively used as heating conductor 1, and polyvinyl chloride, cross-linked polyethylene or fluoroplastic or silicon with a thickness of 0.3~0.5mm are used. Rubber plastic is used as the inner insulation layer 2-1, aluminum-plastic composite film with a thickness of 0.01-0.05mm is used as the shielding layer 3, and polyvinyl chloride plastic or fluoroplastic or silicon rubber plastic with a thickness of 0.3-0.5mm is used as the outer protective layer 5 .

[0054] The production steps are the same as those in Example 1.

Embodiment 3

[0056] Such as Figure 5 , Image 6 As shown, a heating cable with no drain wire and no shielding layer is used.

[0057] An ultra-thin copper-nickel alloy (CuNi10 or CuNi14) strip is used as the heating conductor 1, the insulating layer 2-1, and the outer sheath layer 5.

[0058] Width mm×thickness mm=(4~25)×(0.025~0.6) copper-nickel alloy CuNi10 or CuNi14 alloy strips are respectively used as heating conductor 1, and polyvinyl chloride, cross-linked polyethylene or fluorine with a thickness of 0.3~0.5mm are used Plastics or silicon rubber plastics are used as the inner insulating layer 2-1, and polyvinyl chloride plastics, fluoroplastics or silicon rubber plastics with a thickness of 0.3-0.5 mm are used as the outer protective layer 5.

[0059] The production steps are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com