Glycerol monolaurate microcapsule as well as preparation method and application of glycerol monolaurate microcapsule

A technology of lauric monoglycerin and microcapsules, which is applied in the field of food additives, can solve the problems of poor fluidity, poor taste, and poor solubility and dispersion of glyceryl laurate, and achieve improved solubility and dispersion, good embedding effect, and particle size the right size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

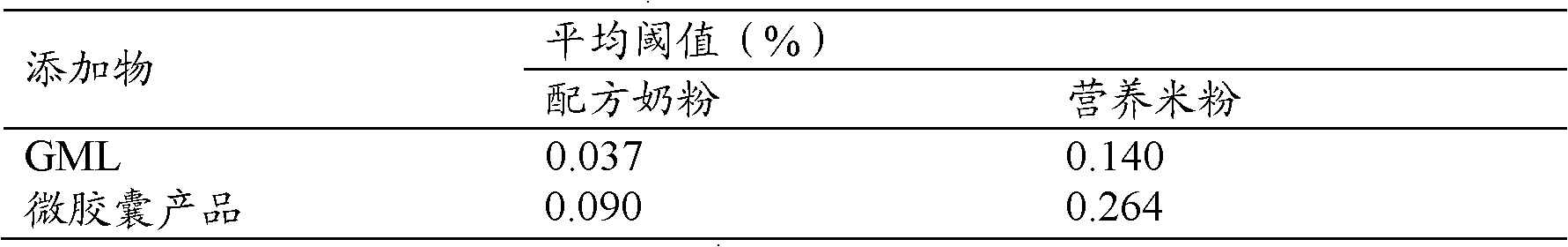

[0046] The influence of embodiment 1-2 emulsifier on microencapsulation efficiency

[0047] Weigh 49g of monoglyceride laurate, 5g of emulsifier, add 120g of water, stir at 60°C until completely dissolved to obtain solution A; then weigh 39.2g of soybean protein isolate, 156.8g of maltodextrin, add 630g of water, Stir at ℃ until completely dissolved to obtain solution B; then add solution A to solution B, and mechanically stir at a speed of 1500rpm for 15min to obtain an emulsion; The temperature is 60 DEG C, and the air inlet temperature is 150 DEG C), and the monoglyceride laurate microcapsule product is obtained.

[0048] Among them, the emulsifiers were soybean lecithin and sucrose ester (HLB value 15); the microencapsulation efficiency results are shown in Table 1.

[0049] Table 1

[0050] serial number

Embodiment 3-7

[0051] Example 3-7 Effect of Wall Material Type and Proportion on Microencapsulation Efficiency

[0052] Weigh 61.25g of monoglyceride laurate, 5g of sucrose ester, add 130g of water, stir at 60°C until completely dissolved to obtain solution A; then weigh 183.75g of wall material, add 620g of water, stir at 60°C until completely dissolved Obtain solution B; then add solution A to solution B, and mechanically stir at a rotating speed of 1500rpm for 15min to obtain an emulsion; homogenize under 30MPa pressure (cycle 1 time), spray dry (feed temperature is 60°C, enter Wind temperature is 150 ℃), makes monolauric acid monoglyceride microcapsule product.

[0053] Among them, the wall material types, proportions and microencapsulation efficiency results are shown in Table 2.

[0054] Table 2

[0055] serial number

Embodiment 8-12

[0056] The influence of embodiment 8-12 homogeneous pressure on microencapsulation efficiency

[0057] Weigh 71.5g of monoglyceride laurate and 3.5g of sucrose ester, add 150g of water, stir at 60°C until completely dissolved to obtain solution A; then weigh 100g of octenyl succinic acid starch ester, 150g of maltodextrin, add 525g Water, stirred at 60°C until completely dissolved to obtain solution B; then add solution A to solution B, and mechanically stir at a speed of 2000rpm for 20 minutes to obtain an emulsion; Drying (the feed temperature is 60° C., and the air inlet temperature is 150° C.) to obtain a monoglyceride laurate microcapsule product.

[0058] Among them, the pressure homogeneity is 20, 30, 40, 50 and 60MPa respectively; the results of microencapsulation efficiency are shown in Table 3. It can be seen from the table that when the pressure is higher than 30MPa, the improvement of microencapsulation efficiency is not obvious.

[0059] table 3

[0060] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com