Method for removing ginkgolic acid from ginkgo biloba extract

A technology for ginkgo biloba leaves and extracts, applied in the field of traditional Chinese medicine preparation, can solve the problems of inability to guarantee uniform and stable product quality, unfriendly operators and the environment, organic solvent residues and the like, and achieve uniform and stable product quality, low production cost, and increased content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

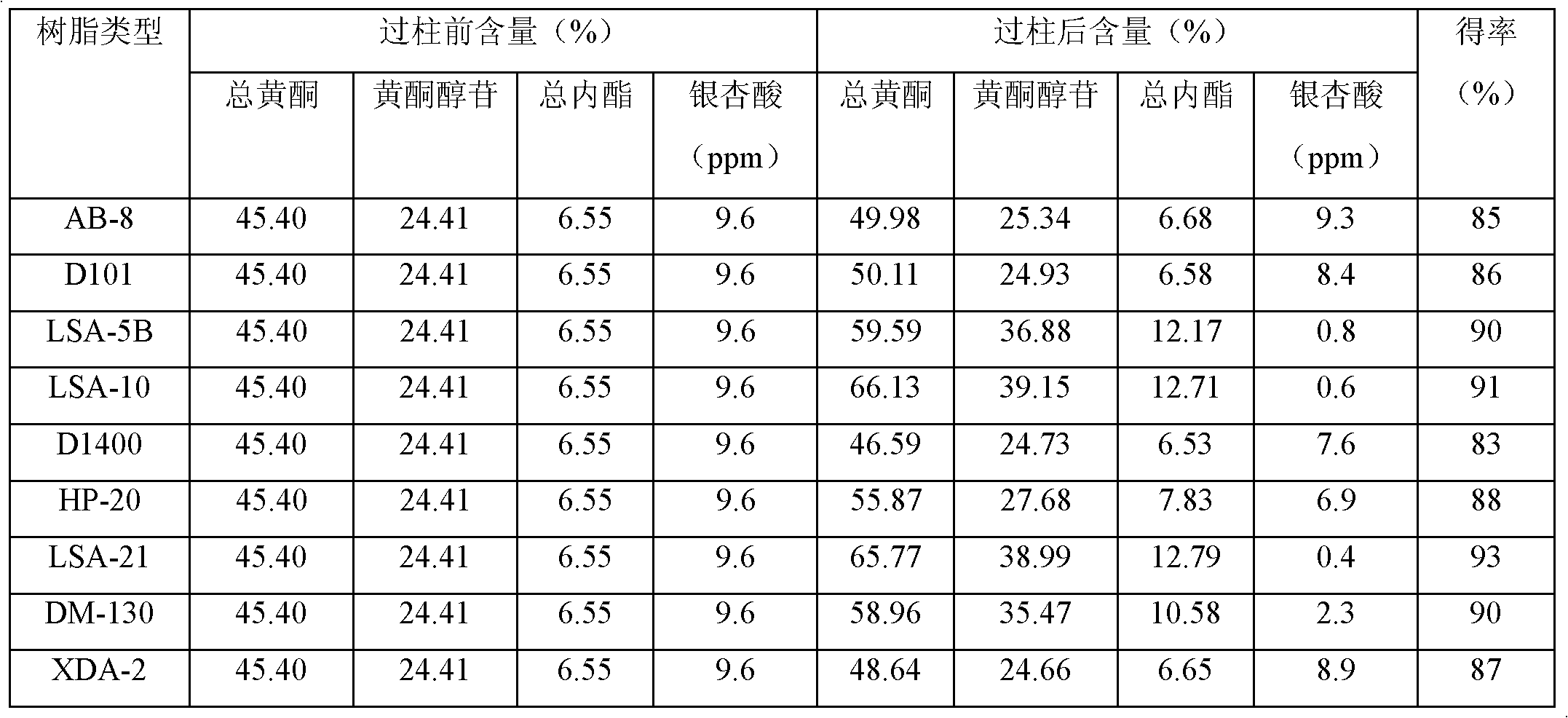

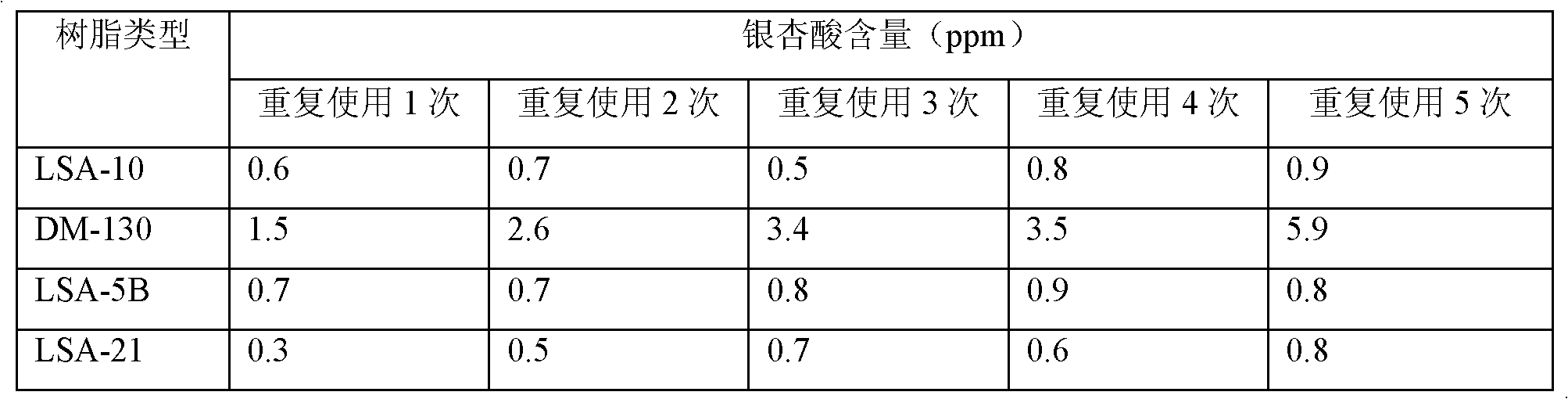

Embodiment 1

[0029] Dried Ginkgo biloba extract 1kg, crushed to pass through a 100-mesh sieve, stirred and extracted 3 times with hot water at 60°C, each time the amount of water was 3 times the dry weight of Ginkgo biloba extract, extracted for 2 hours each time, filtered, and combined for 3 The second filtrate was used to adjust the relative density to 1.05 with water to obtain an extract. Add 2ml of extract per gram of resin, pass through LSA-10 macroporous adsorption resin exchange column, the ratio of column diameter to height is 1:8, first wash with 3 times the volume of purified water, and then use 16 times the volume of the column, mass The ethanol solution with a percentage concentration of 65% is eluted at a speed of 20ml / min, the eluate is collected, and the ethanol is recovered under reduced pressure to obtain a concentrated solution. The concentrated solution is vacuum-dried below 60°C to obtain about 930g dry extract powder. The yield is 93%. According to the "Chinese Pharma...

Embodiment 2

[0031] Dried Ginkgo biloba extract 2kg, crushed to pass through a 100-mesh sieve, ultrasonically extracted 5 times with 50°C hot water, each time the amount of water was twice the weight of Ginkgo biloba extract, extracted for 1.5 hours each time, filtered, and combined 5 times filtrate, and then adjust the relative density of the filtrate to 110 with water to obtain an extract. Add 2.5 ml of extract per gram of resin, and pass through LSA-21 macroporous adsorption resin exchange column with a diameter-to-height ratio of 1:9. First wash with 4 times the volume of purified water, then elute with 18 times the volume of the column and ethanol solution with a concentration of 70% by mass at a rate of 25ml / min, collect the eluate, recover ethanol under reduced pressure, and obtain a concentrated solution, which is sprayed Dried to obtain about 1910g of dry extract powder, the yield was 95.5%. According to the "Chinese Pharmacopoeia" 2010 edition Ginkgo biloba extract content deter...

Embodiment 3

[0033] Dried Ginkgo biloba extract 2.5kg, crushed to pass through a 100 mesh sieve, stirred and extracted with 40°C hot water for 4 times, each time the amount of water was 2.5 times the weight of Ginkgo biloba extract, extracted for 2 hours each time, filtered, combined 4 The second filtrate was used to adjust the relative density to 1.08 with water to obtain an extract. The ratio of adding 3ml extract per gram of resin is passed through LSA-5B macroporous adsorption resin exchange column, and the diameter-height ratio of the column is 1:10. First wash with 2 times the volume of purified water, then use 17 times the column volume mass percentage concentration of 80% ethanol solution to elute at a speed of 30ml / min, collect the eluate, and recover the ethanol under reduced pressure to obtain a concentrated solution. After drying in vacuum below ℃, about 2.14kg of dry extract powder was obtained, and the yield was 85.6%. According to the "Chinese Pharmacopoeia" 2010 edition Gi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com