Automatic welding method for microdeformation of cylinder sleeve of bottom upright of large hydraulic support

A hydraulic support and automatic welding technology, which is applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of high heat input, large deformation, and unreachable pistons, and achieve high laser energy input, fast welding speed, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

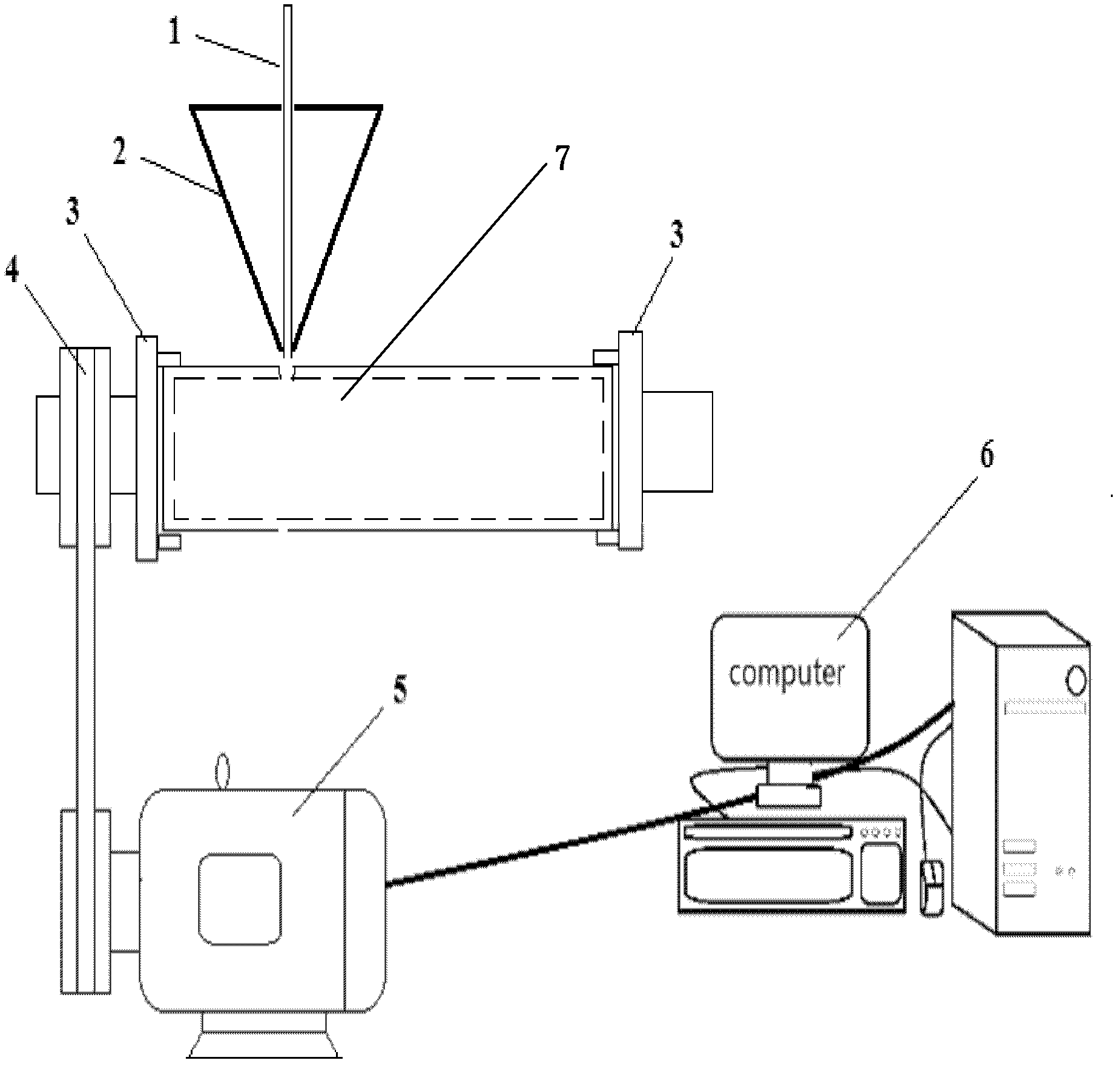

Image

Examples

Embodiment 1

[0026] An automatic welding method for micro-deformation of the cylinder liner of the bottom column of a large hydraulic support, which is carried out according to the following steps:

[0027] Step 1: Fix the hydraulic support bottom column cylinder liner and its base to be welded on the chuck of the CNC machine tool;

[0028] Step 2: Loading the iron-based alloy powder into a powder feeding device coaxial with the optical axis of the laser beam of the laser;

[0029] Step 3: Set the parameters of the powder feeding device and the laser welding parameters of the laser;

[0030] Laser welding parameters of the laser: the laser power is 2000W, and the welding speed is 3mm / s;

[0031] Powder feeding device parameters: powder feeding volume is 230g / min;

[0032] Step 4: Turn on the laser, powder feeding device and CNC machine tool at the same time to automatically complete the welding process.

[0033] The composition of the iron-based alloy powder described in step 2 is (%): ...

Embodiment 2

[0037] An automatic welding method for micro-deformation of the cylinder liner of the bottom column of a large hydraulic support, which is carried out according to the following steps:

[0038] Step 1: Fix the hydraulic support bottom column cylinder liner and its base to be welded on the chuck of the CNC machine tool;

[0039] Step 2: Loading the iron-based alloy powder into a powder feeding device coaxial with the optical axis of the laser beam of the laser;

[0040] Step 3: Set the parameters of the powder feeding device and the laser welding parameters of the laser;

[0041] Laser welding parameters of the laser: the laser power is 2500W, and the welding speed is 5mm / s;

[0042] Powder feeding device parameters: powder feeding volume is 248g / min;

[0043] Step 4: Turn on the laser, powder feeding device and CNC machine tool at the same time to automatically complete the welding process.

[0044] The composition of the iron-based alloy powder described in step 2 is (%): ...

Embodiment 3

[0048] An automatic welding method for micro-deformation of the cylinder liner of the bottom column of a large hydraulic support, which is carried out according to the following steps:

[0049] Step 1: Fix the hydraulic support bottom column cylinder liner and its base to be welded on the chuck of the CNC machine tool;

[0050] Step 2: Loading the iron-based alloy powder into a powder feeding device coaxial with the optical axis of the laser beam of the laser;

[0051] Step 3: Set the parameters of the powder feeding device and the laser welding parameters of the laser;

[0052] Laser welding parameters of the laser: the laser power is 3000W, and the welding speed is 6mm / s;

[0053] Powder feeding device parameters: powder feeding volume is 258g / min;

[0054] Step 4: Turn on the laser, powder feeding device and CNC machine tool at the same time to automatically complete the welding process.

[0055] The composition of the iron-based alloy powder described in step 2 is (%):

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com