Method and apparatus for machining based on titled laser scanning

A processing method and technology of processing equipment, applied in the field of laser processing methods and equipment, can solve the problems of laser processing method limitation, uneven surface or micro-cracks, slow processing speed, etc., and achieve the effect of enhancing the quality of cutting and scribing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The above and other objects, features and advantages of the present invention will be apparent from the following detailed description of preferred embodiments of the present invention taken in conjunction with the accompanying drawings.

[0026] Reference will now be made in detail to preferred embodiments of the present invention with reference to the accompanying drawings, but the invention is not limited or limited by these embodiments.

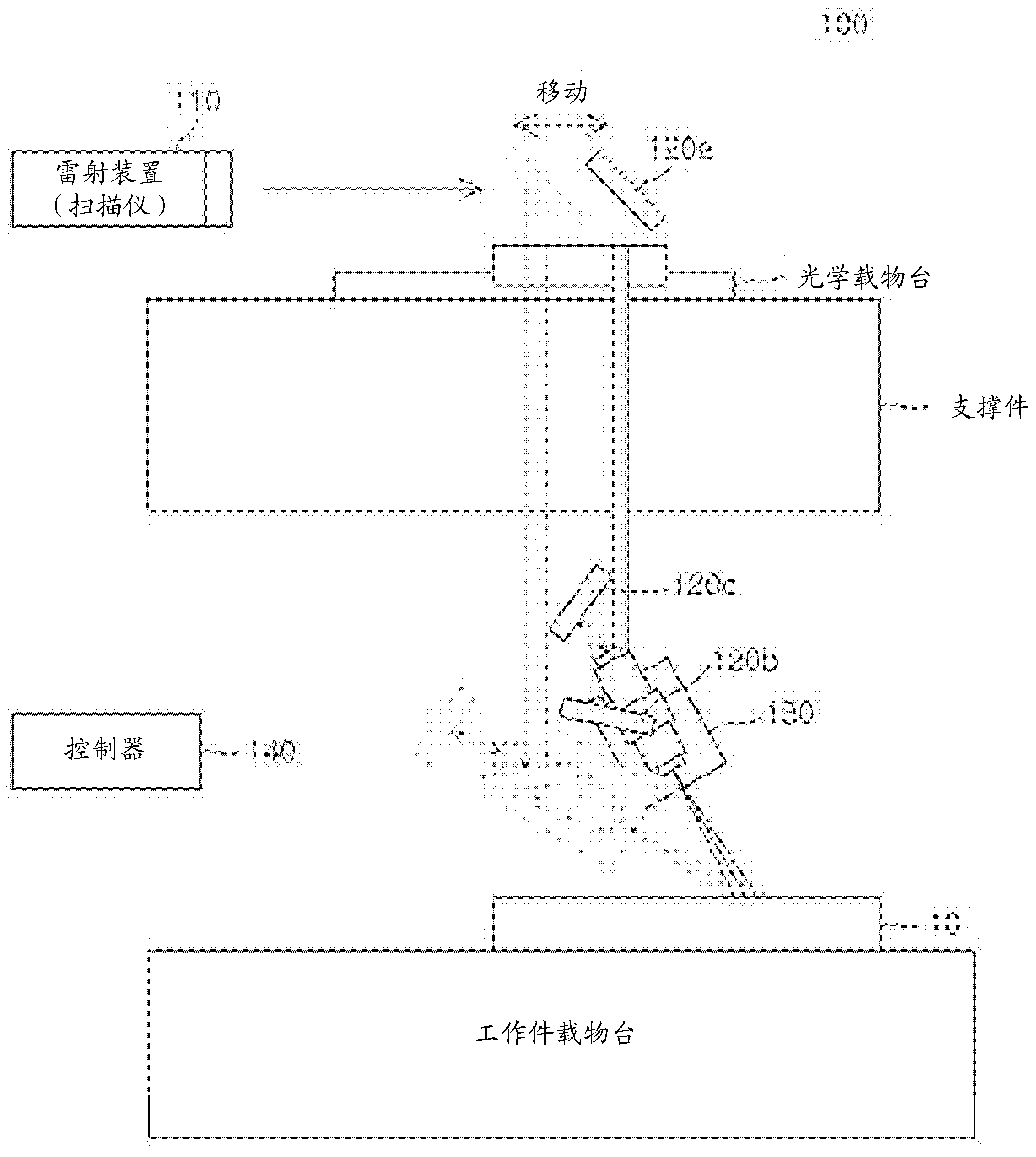

[0027] figure 2 It is a schematic diagram for describing a laser processing device 100 according to a preferred embodiment of the present invention.

[0028] see figure 2 , the laser processing equipment 100 according to the present invention includes a laser device 110 , a first optical system 120 having a first mirror 120 a , a second mirror 120 b and a third mirror 120 c , a second optical system 130 and a controller 140 . The laser processing equipment 100 further includes a stage for fixing the workpiece 10 , and the stage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com