Process and device for treating and recycling chromium-containing waste liquor

A waste liquid and process technology, applied in the field of chromium-containing waste liquid disposal and recovery process and its disposal and recovery device, can solve the problems of large investment, high operation and management cost, heavy pollution control burden of enterprises, etc., and achieve obvious economic and social benefits and save money. Equipment and operating costs to achieve the effect of cleaner production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

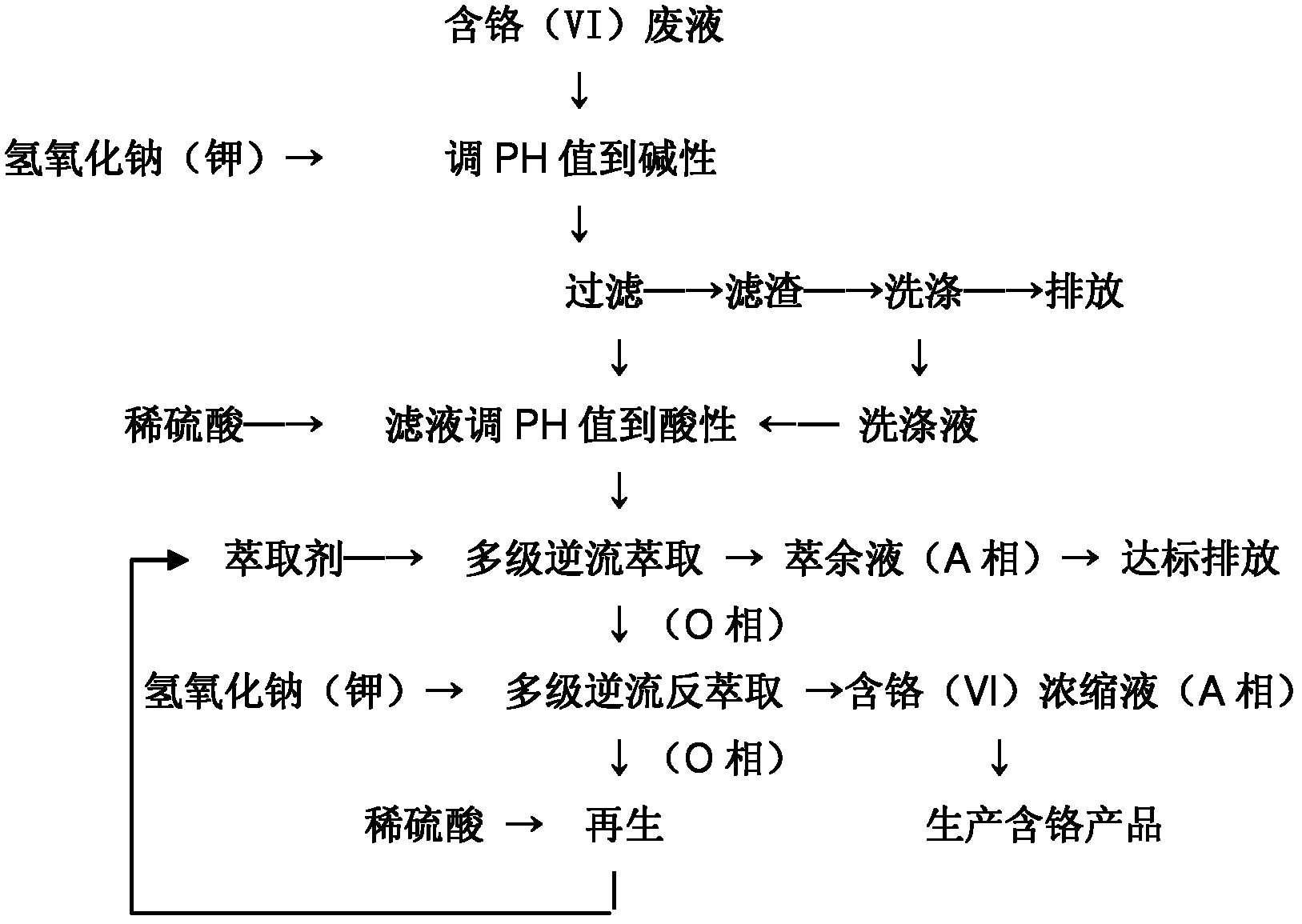

[0041] Such as figure 1 As shown, the chromium-containing waste liquid disposal and recycling process includes the following steps:

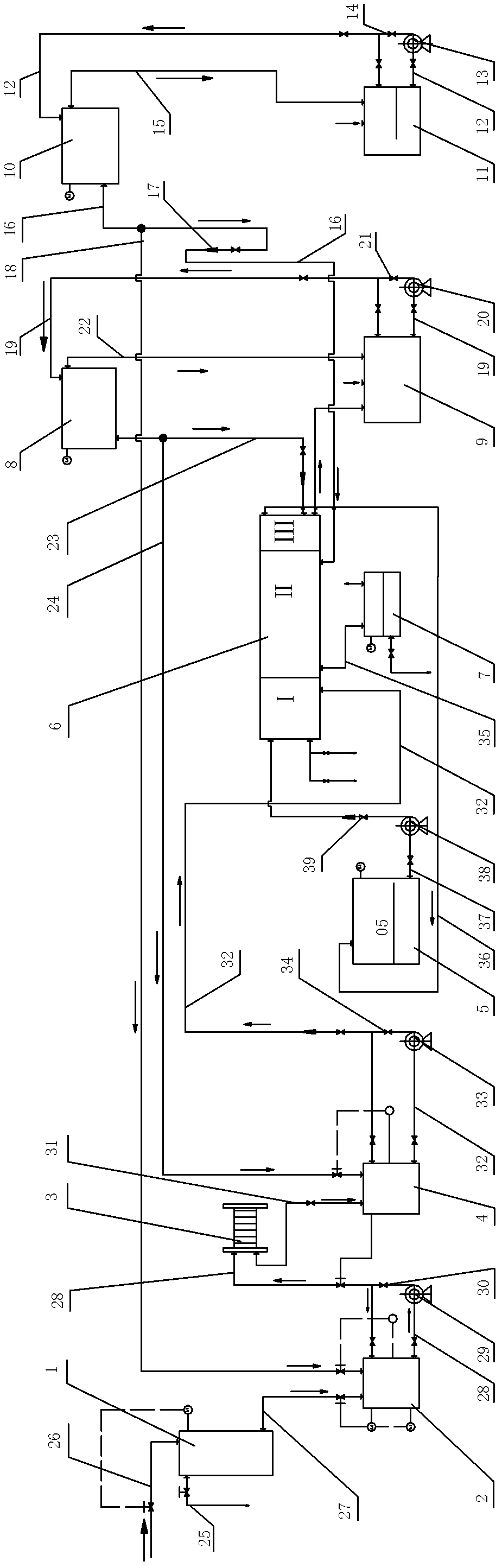

[0042] 1) Using trialkyl tertiary amine (N235) as the extractant and kerosene as the solvent, prepare a N235-kerosene solution containing 30wt% of the extractant in the extractant recovery storage tank 5 for use;

[0043] 2) Prepare concentrated sulfuric acid or waste sulfuric acid with a concentration of 10% by weight or more in the acid mixing tank 9 to prepare dilute sulfuric acid with a sulfuric acid content of 10% by weight; then pump to the high-level acid storage tank 8 for standby;

[0044] 3) Put the industrial sodium hydroxide or potassium hydroxide in the alkali distributing tank 11 and add water to dissolve it to prepare a sodium hydroxide solution or potassium hydroxide solution with a concentration of 10wt%; then pump to the high-position alkali storage tank 10 for standby;

[0045] 4) Connect the chromium-containing waste liquid storage ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com