Method for manufacturing building material by using high-water content sludge in urban sewage treatment plant

A technology of urban sewage and high water content, applied in the field of comprehensive resource utilization to achieve the effect of solving secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The sample used in this example is fresh sludge from Fengtai Sewage Treatment Plant. The experimental manufacturer is Tianbao Active Coal Gangue Mixed Raw Material Factory in Fengtai County. Fengtai Sewage Treatment Plant is one of the sewage treatment projects of the National South-to-North Water Diversion Project and was completed in August 2008. Putting into operation, the first phase of the project will treat 25,000 tons of sewage per day, and the actual daily processing will be 22,000 tons, and the annual output of sludge with a moisture content of 80% will be about 3,000 tons.

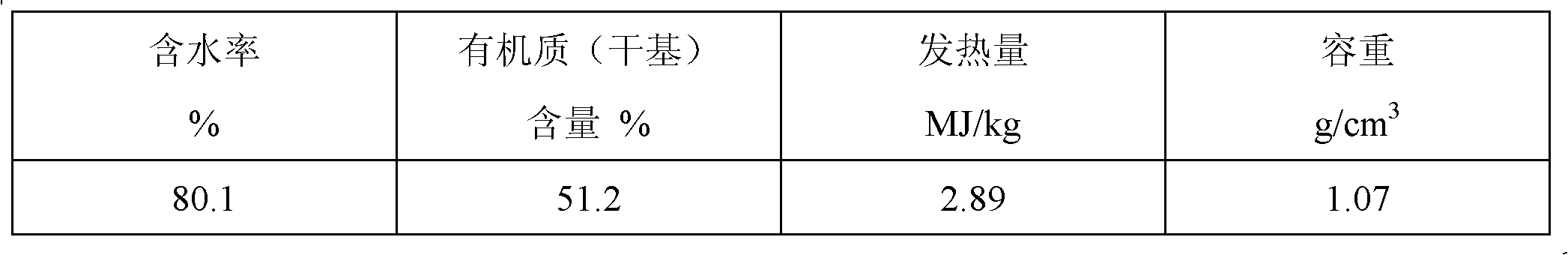

[0023] The main characteristics and heavy metal content of fresh sludge are shown in Table 1 and Table 2:

[0024] Table 1 Basic characteristics of sludge samples

[0025]

[0026] Table 2 Sludge sample (dry weight) heavy metal content (mg / kg)

[0027] Cu

Zn

Pb

Cd

Cr

Ni

Hg

As

254.1

462.5

121.6

1.9

101.2

49.7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com