Method for composing sludge by adding mineralized waste

A technology of mineralized garbage and composting method, which is applied in the field of resource utilization of organic waste, to achieve the effects of reducing investment, improving fertilizer efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

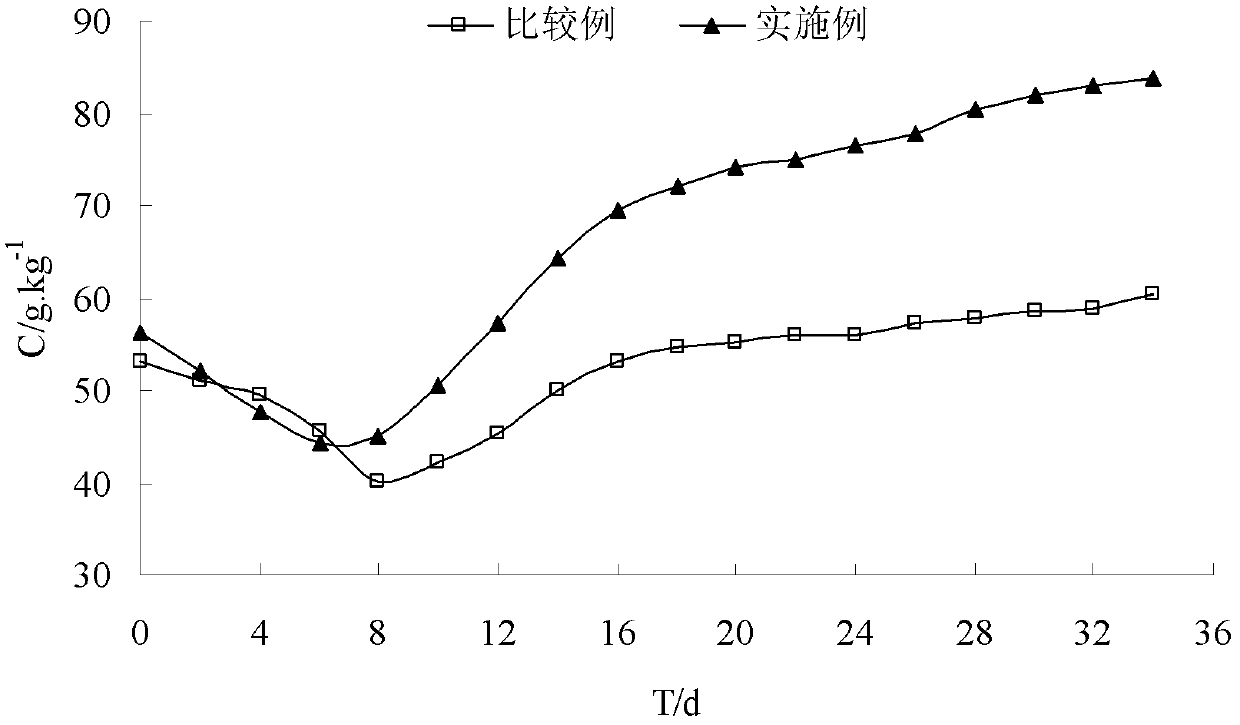

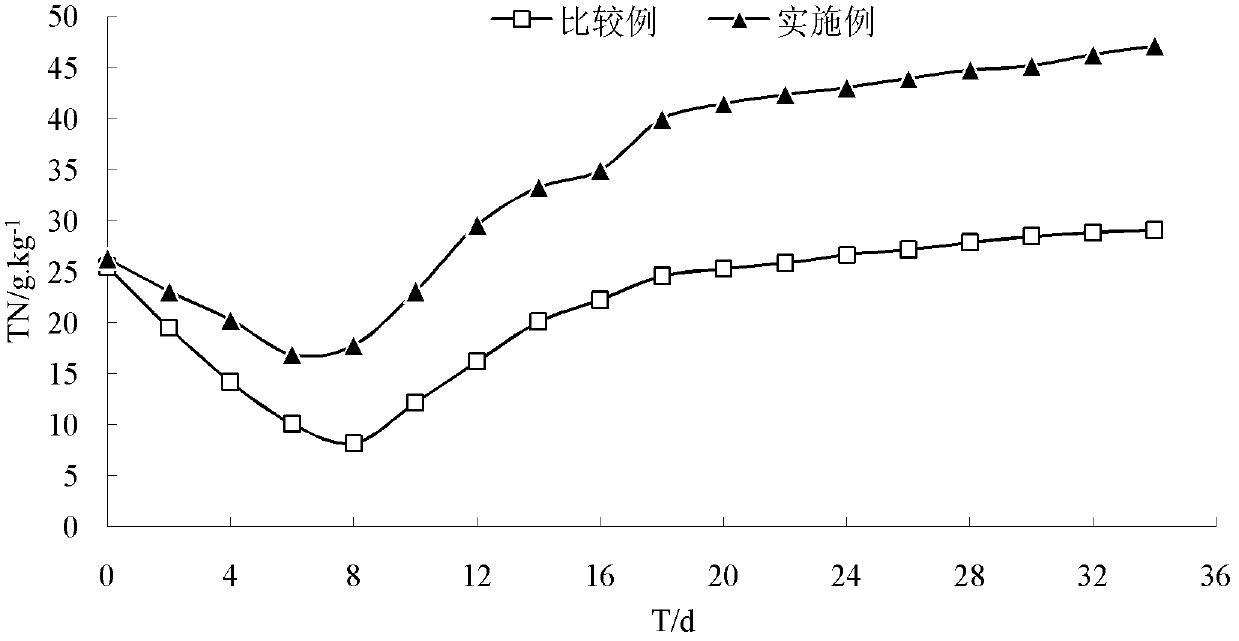

[0025] The crop straw was pulverized to 2-4cm, and its moisture content was 13.58%, and the C / N ratio was 81.32. The moisture content of the sludge from the sewage treatment plant was 83.19%, and the C / N ratio was 11.29. was 26.53%, and C / N was 16.21. Mix the sludge, crop straws and mineralized garbage uniformly according to the following requirements, so that the mineralized garbage content is 15.21% (dry weight), the moisture content is 63.21%, and the C / N is 25.1, and then the mixed material is loaded into the composting reaction After the warehouse is installed, the surface layer is flattened, and then 5cm thick mineralized waste is laid on it, and the oxygen supply is forced to ventilate at a rate of 0.4L / (min.kg). When the oxygen concentration at the outlet is higher than 18%, the oxygen supply is stopped. Oxygen supply was started when the outlet oxygen concentration was lower than 10%, and the fermentation was completed in 17 days. Take the material out of the compost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com