Synthesis method of calcium ion selective chelating agents

A synthetic method and selective technology, applied in the field of synthesis of calcium ion selective chelating agent, can solve the problems of cumbersome steps, low product purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

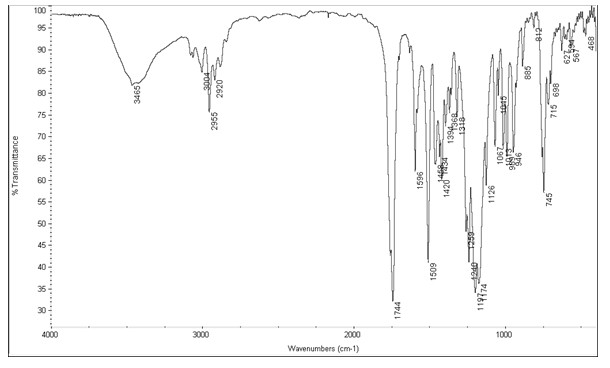

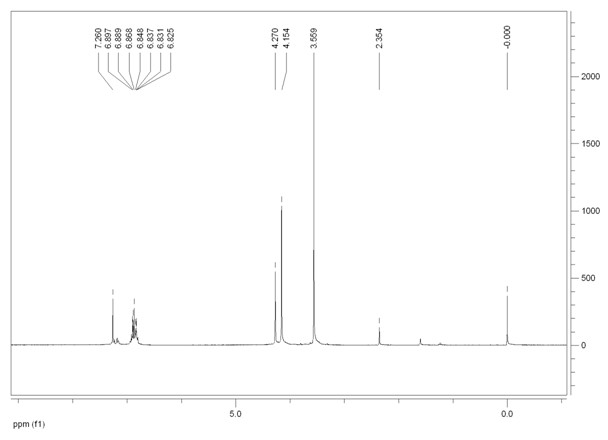

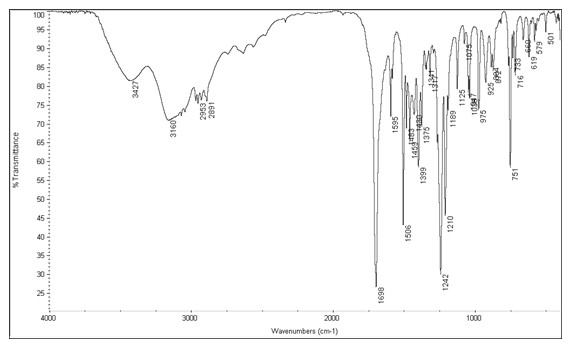

Image

Examples

Embodiment Construction

[0020] The synthetic method of compound 1a comprises the following steps:

[0021] 1. The synthetic reaction steps of compound 1a:

[0022] The first step: add 19.52g (80mmol) 1,2-bis(2-aminophenoxy)ethane, 3.344g (62.4mmol) anhydrous sodium iodide, 72ml (416mmol) of diisopropylethylamine and 120ml of acetonitrile.

[0023] The second step: Slowly heat up and stir. The temperature of the internal bath was raised to 55°C, and 38.4ml (416mmol) of methyl bromoacetate was added dropwise at a constant speed.

[0024] Step 3: after the dropwise addition, the system is filled with nitrogen and sealed, and the temperature is raised to 80° C. in the system again, and then refluxed for 20 hours.

[0025] 2. Post-processing steps for compound 1a synthesis

[0026] Step 4: After the reflux is completed, add 140ml of toluene into the four-neck flask, stir for 30 minutes, and then let stand for 30 minutes. After standing, pour the upper clear layer into a 500ml beaker, add 50ml of tolu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com