Blast furnace slag-iron separation device, slag-iron separation method and discharged blast furnace slag-iron recovery method

The technology of a separation device and separation method is applied in the field of blast furnace slag iron recovery and blast furnace slag iron separation device, which can solve the problems of burning slag storage container transportation path, poor separation effect of slag iron, slag storage container burn-through, etc., to achieve The effect of shortening the interval time of tapping, increasing the utilization factor of blast furnace, and reducing the amount of iron in slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

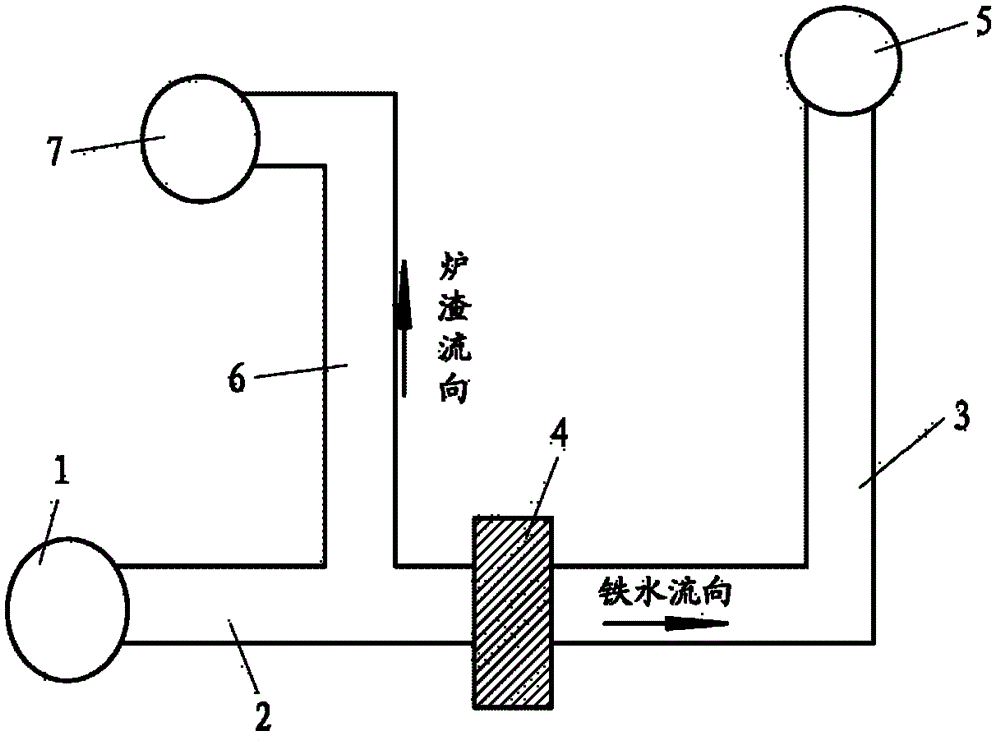

Embodiment 1

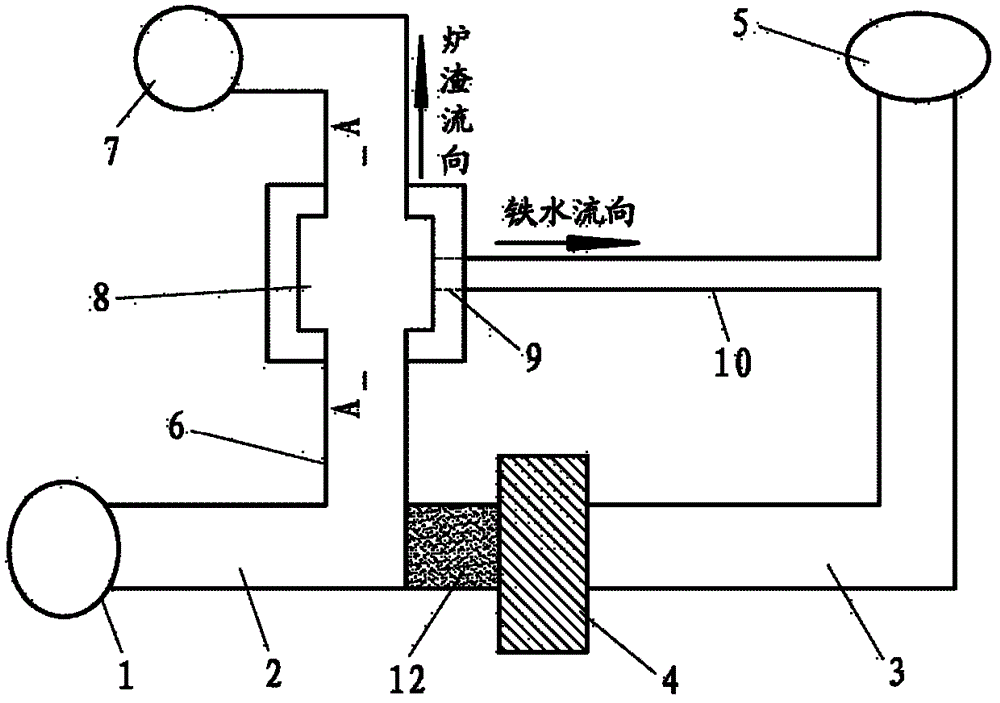

[0046] According to attached Figure 3B In the shown structure, the structural parts of sinking pool 8, small taphole 9, short vertical section 11 and molten iron branch ditch 10 are fabricated in the slag ditch by on-site casting. After the furnace is turned on to supply air and ignite, due to the high temperature of the furnace, the fluidity of molten iron and slag is poor. In order to prevent the effluent from flowing into the skimmer 4 and cause the skimmer 4 to become stuck and affect the normal separation of slag and iron in front of the furnace, use a The yellow sand forms a barrier before and within the skimmer 4 .

[0047] The first iron tapping after the blast furnace is opened. Before the blast furnace taphole 1 is opened for the first time, the small taphole 9 is blocked. After the blast furnace taphole 1 is opened, the effluent flows directly from the slag-iron ditch 2 into the slag ditch 6, with a slag output of 10 tons and no iron. Therefore, there is no need...

Embodiment 2

[0054] Due to the long-term slag containing more iron in a blast furnace, the iron loss of the blast furnace is relatively high. The slag ditch was modified to recover the molten iron in the slag. Since this blast furnace has a single tap hole, the tapping interval is very short, generally less than 30 minutes. In order to achieve continuous tapping, the Figure 3B The blast furnace slag-iron separation device with the structure shown, and the structural parts of the iron sinking pool 8, the small taphole 9, the short vertical section 11 and the molten iron branch ditch 10 are fabricated by the method of on-site casting. The slag iron ditch 2 and the skimmer 4 do not make any changes.

[0055] After the transformation, before opening the blast furnace taphole 1 for the first time, the small taphole 9 needs to be blocked. After the blast furnace taphole 1 is opened, the effluent passes through the slag skimmer 4 and is separated into slag containing a small amount of molten i...

Embodiment 3

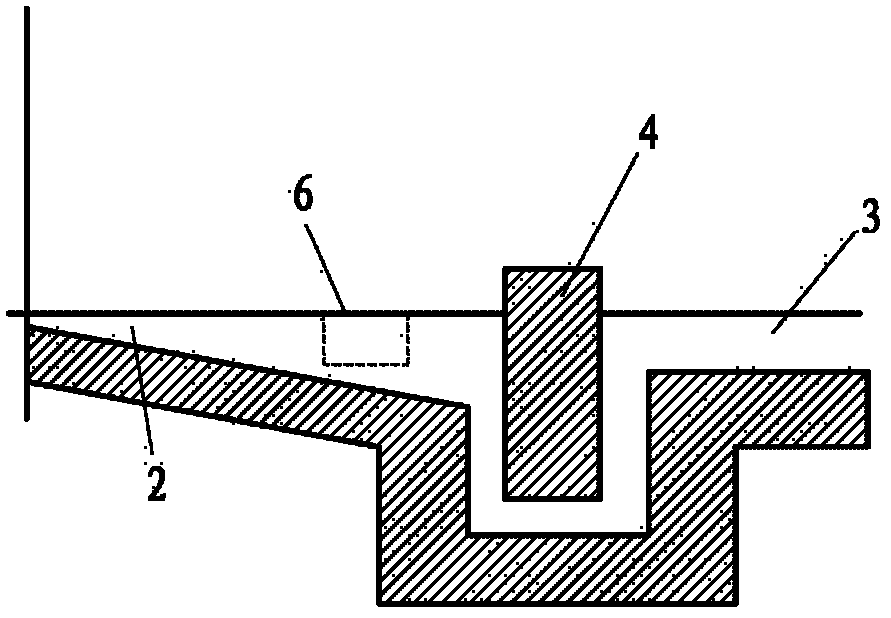

[0059] A vanadium-titanium ore smelting blast furnace has a high iron loss due to the long-term slag containing a lot of iron, so the structure of the separation device was modified. Since this blast furnace has three taps, the tapping interval is longer. To prevent the solidification of molten iron in the short vertical section, a Figure 3A The blast furnace slag-iron separation device with the structure shown is to dig deep and wide the upstream section of the slag ditch 6 to form a sinking iron pool 8, and compact it with baking-free mud on the surface; Iron bent pipe (which can be made by bending the oxygen blowing pipe) to form a small taphole 9, and an inclined molten iron branch ditch 10 is temporarily set on the outside, and the molten iron branch ditch 10 is connected to the sinking iron pool through the small taphole 9 8 connected.

[0060] When tapping, after the blast furnace taphole 1 is opened, the effluent is separated into slag containing a small amount of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com