Method and device for preparing microtexture through laser photoetching assisted electrochemical deposition

A laser lithography and deposition device technology, applied in the field of laser lithography-assisted electrochemical deposition to prepare micro-textures, can solve the problems of poor substrate bonding performance, low strength, loose tissue, etc., and achieve controllable structure, short wavelength, and composition controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

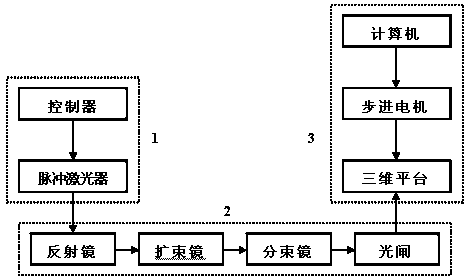

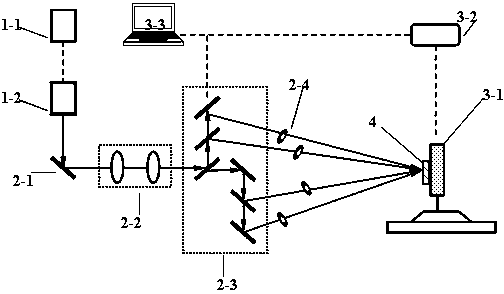

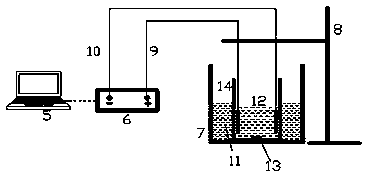

[0033] Example 1: The method for preparing micro-textures is to use pulsed laser lithography to photoetch the surface of the metal material that has been spin-coated with photoresist, then immerse it in a developer to remove the exposed photoresist, and then use electrochemical deposition The technology carries out the controlled electrodeposition of the composite coating on the surface of the material, and finally removes the unexposed photoresist, and obtains the surface composite coating with regular micro-texture on the surface of the metal material to maximize the surface tribological performance;

[0034] Specific steps are as follows:

[0035] 1. Preliminary preparation: prepare material samples and related equipment, establish the pulse laser lithography system device and electrochemical deposition device used; spin coating of photoresist on the surface of the substrate material: spin coating and drying with a homogenizer, at 70~ Dry for 20min at 110℃; adjust the solution n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com