Vehicle high-power DC/DC driving power supply and driving method

A driving power supply and high-power technology, which is applied in the direction of electrical devices, control drives, and output power conversion devices, can solve problems such as soft output characteristics, voltage changes, and poor dynamic performance, so as to reduce the number of series used, Reduced management costs and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0015] Basic idea of the present invention is:

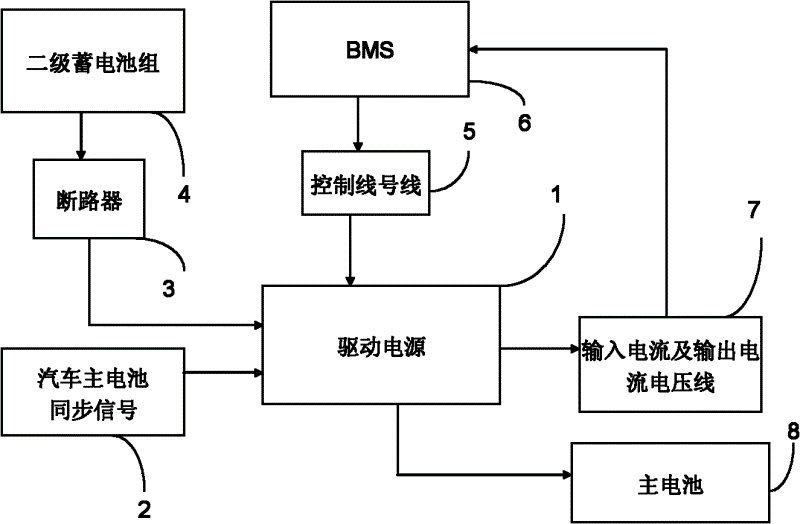

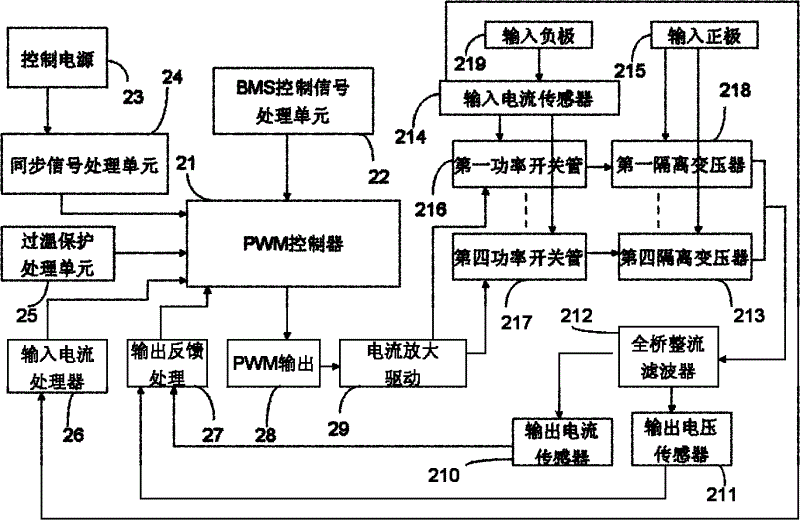

[0016] 1. Adopt a multi-module structure, so that the input is equivalent to parallel connection, and the output is in series, so that the lower secondary battery voltage is converted into a higher output voltage required by the car; figure 2 As shown in the method of using four power switch tubes, the output of the input current sensor 214 is respectively connected to the four power switch tubes.

[0017] 2. The push-pull topology is adopted, the input and output transmit energy through the isolated transformer component, and the input and output are completely isolated, such as figure 2 As shown, four isolation transformers are used, the isolation transformer 218 is connected to the isolation transformer 213, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com