Green tea beverage and preparation method thereof

A technology of green tea beverage and production method, which is applied in the direction of tea extraction, etc., can solve the problems of destroying the nutritional content of tea leaves, inconvenient to carry, cannot be stored for a long time, and achieve the effect of maintaining concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

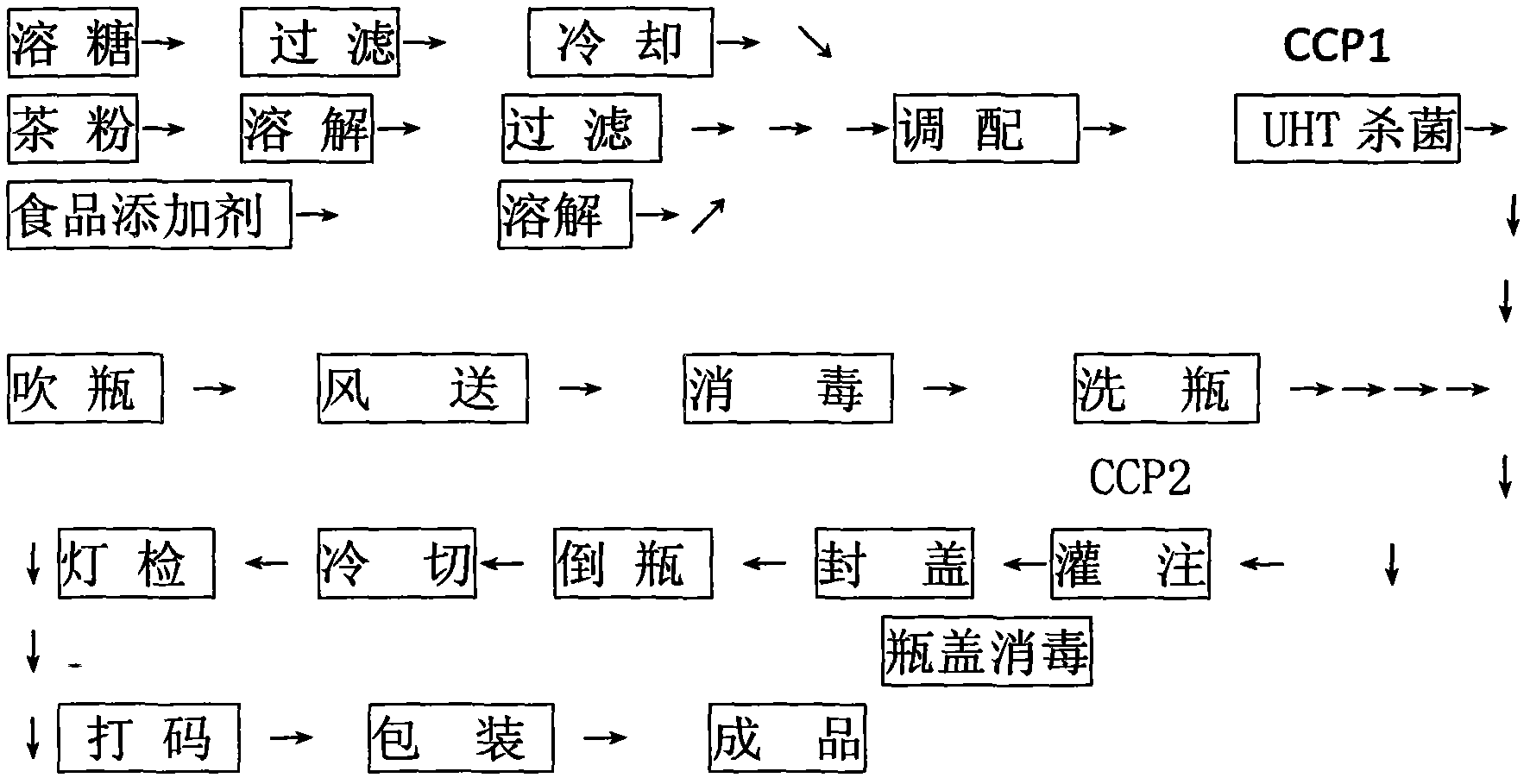

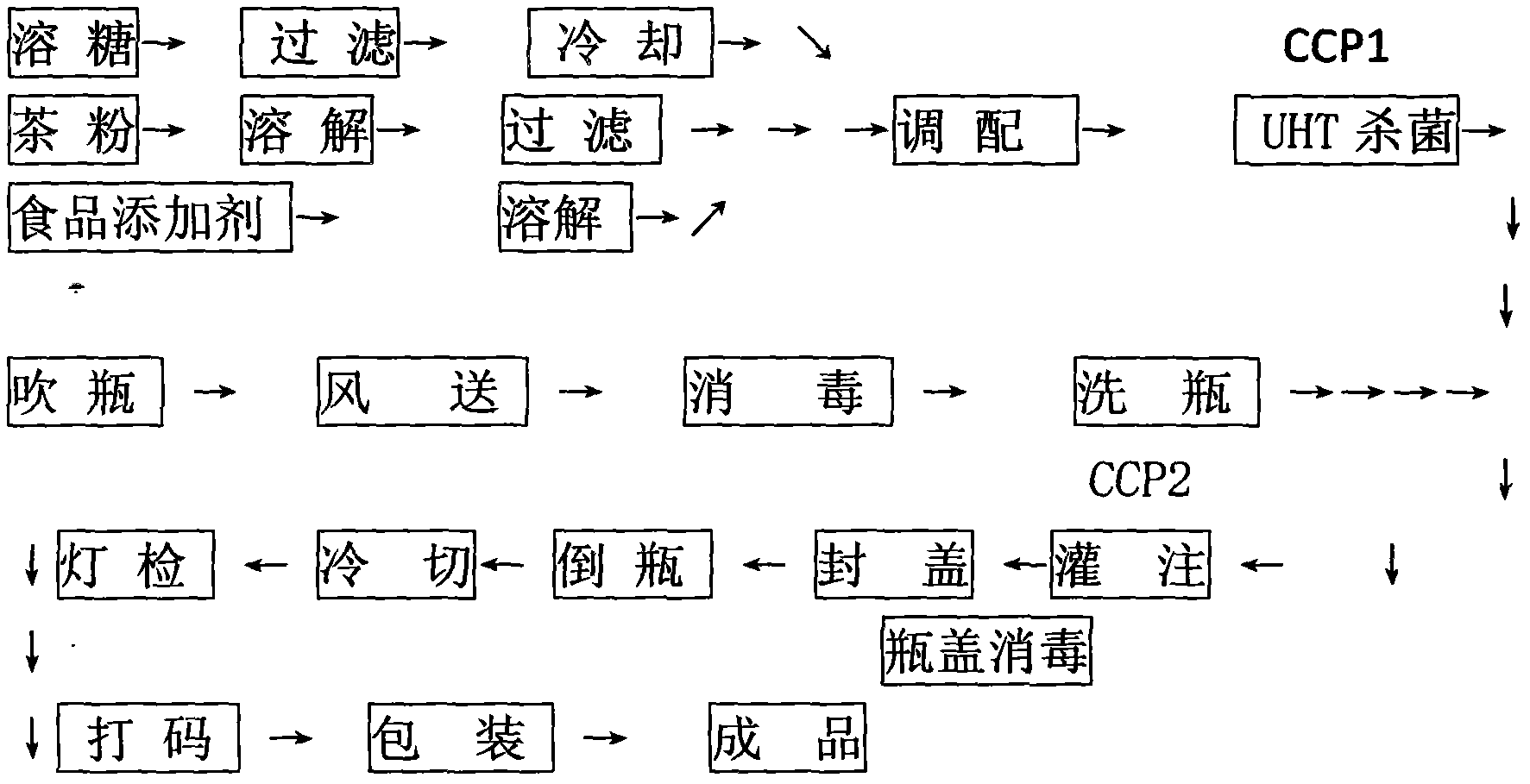

Image

Examples

Embodiment 1

[0021] (1) Get 100 kilograms of Maojian tea and grind it into 85 mesh tea powder;

[0022] (2) Carry out the first leaching by tea water ratio 1: 30, temperature 80 ℃, extraction time 15 minutes;

[0023] (3) cooling the extracted tea juice to 10°C within 3 minutes, coarsely filtering, finely filtering;

[0024] (4) the tea residue after the first extraction is carried out for the second extraction according to the procedure of step (2), and the fine filtrate is also obtained;

[0025] (5) mix the fine filtrate of twice gained, by mass proportion: add the Vc of 0.02%, the honey of 0.01%, the glycine of 0.02%, the sodium hexametaphosphate of 0.03%, the edible sugar of 2%;

[0026] (6) Make the pH value of the tea liquid reach 5.8 through acid-base blending;

[0027] (7) High temperature instantaneous sterilization, temperature 118°C, time 5 seconds;

[0028] (8) Cool to 70°C and hot fill into bottles.

Embodiment 2

[0030] (1) Get 100 kilograms of Maojian tea and grind it into 90 mesh tea powder;

[0031] (2) Carry out the first leaching by tea-water ratio 1:30, temperature 82 ℃, extraction time 18 minutes;

[0032] (3) cooling the extracted tea juice to 12°C within 3 minutes, coarsely filtering, finely filtering;

[0033] (4) the tea residue after the first extraction is carried out for the second extraction according to the procedure of step (2), and the fine filtrate is also obtained;

[0034] (5) mix the fine filtrate of twice gained, by mass proportion: add the Vc of 0.03%, the honey of 0.02%, the glycine of 0.03%, the sodium hexametaphosphate of 0.04%, the edible sugar of 3%;

[0035] (6) Make the pH value of the tea liquid reach 6.0 through acid-base blending;

[0036] (7) High temperature instantaneous sterilization, temperature 118°C, time 5 seconds;

[0037] (8) Cool to 75°C and hot fill into bottles.

Embodiment 3

[0039] (1) Get 100 kilograms of Maojian tea and grind it into 95 mesh tea powder;

[0040] (2) Carry out the first leaching by tea water ratio 1: 30, temperature 85 ℃, extraction time 20 minutes;

[0041] (3) cooling the extracted tea juice to 15°C within 3 minutes, coarsely filtering, finely filtering;

[0042] (4) the tea residue after the first extraction is carried out for the second extraction according to the procedure of step (2), and the fine filtrate is also obtained;

[0043] (5) mix the fine filtrate of twice gained, by mass proportion: add the Vc of 0.04, the honey of 0.03%, the glycine of 0.04%, the sodium hexametaphosphate of 0.05%, the edible sugar of 3%;

[0044] (6) Make the pH value of the tea liquid reach 6.2 through acid-base blending;

[0045] (7) High temperature instantaneous sterilization, temperature 118°C, time 5 seconds;

[0046] (8) Cool to 80°C and hot fill into bottles.

[0047] After the product of the present invention is stored for 10 month...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com