Three dimensional (3D) vibration device with accurately controlled amplitude and frequency and manufacture method thereof

A technology of vibration equipment and frequency, applied in the direction of fluid using vibration, can solve the problems of poor repeatability, limited high density, complicated equipment, etc., to achieve the effect of convenient replacement, increased loose packing density, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

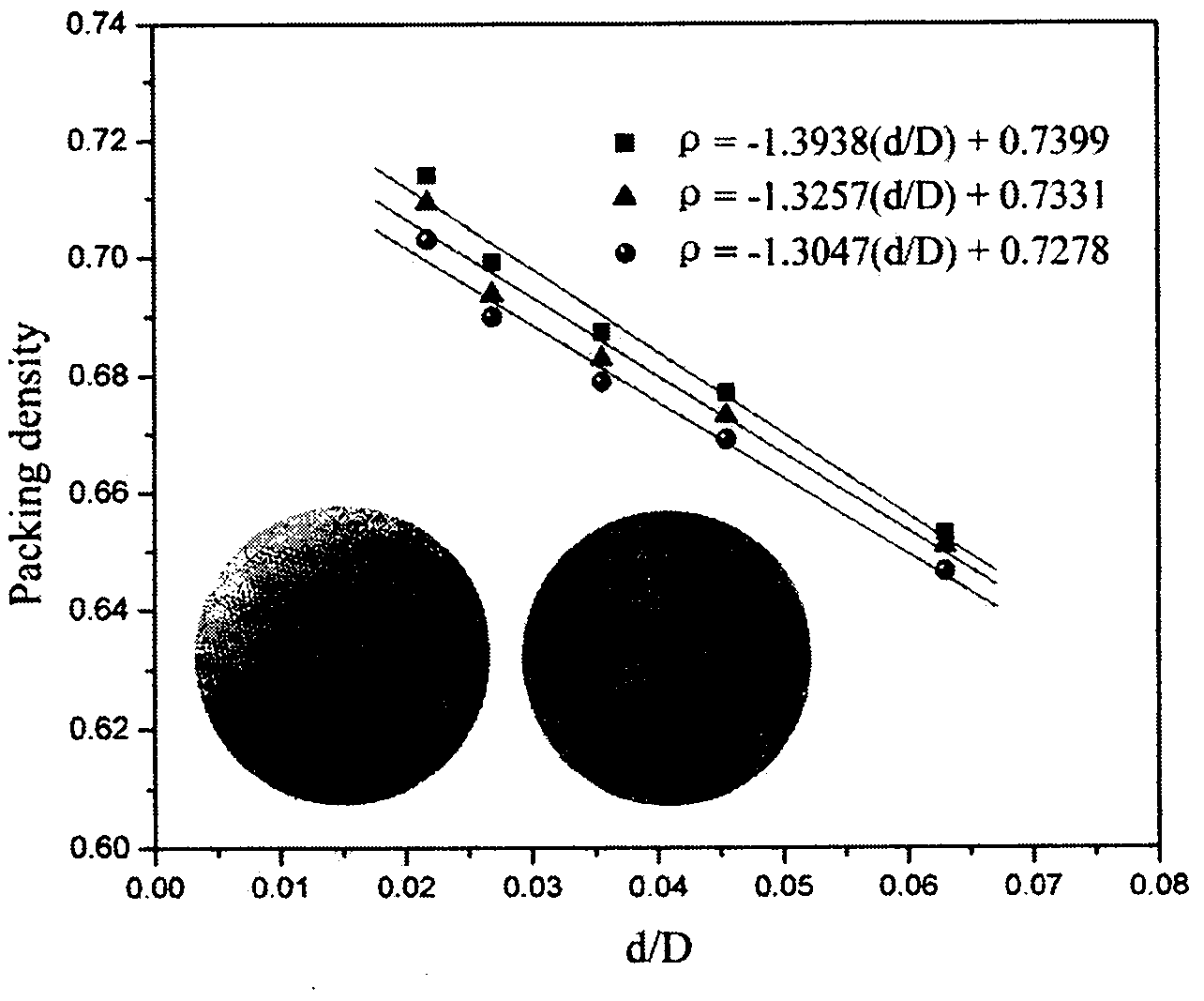

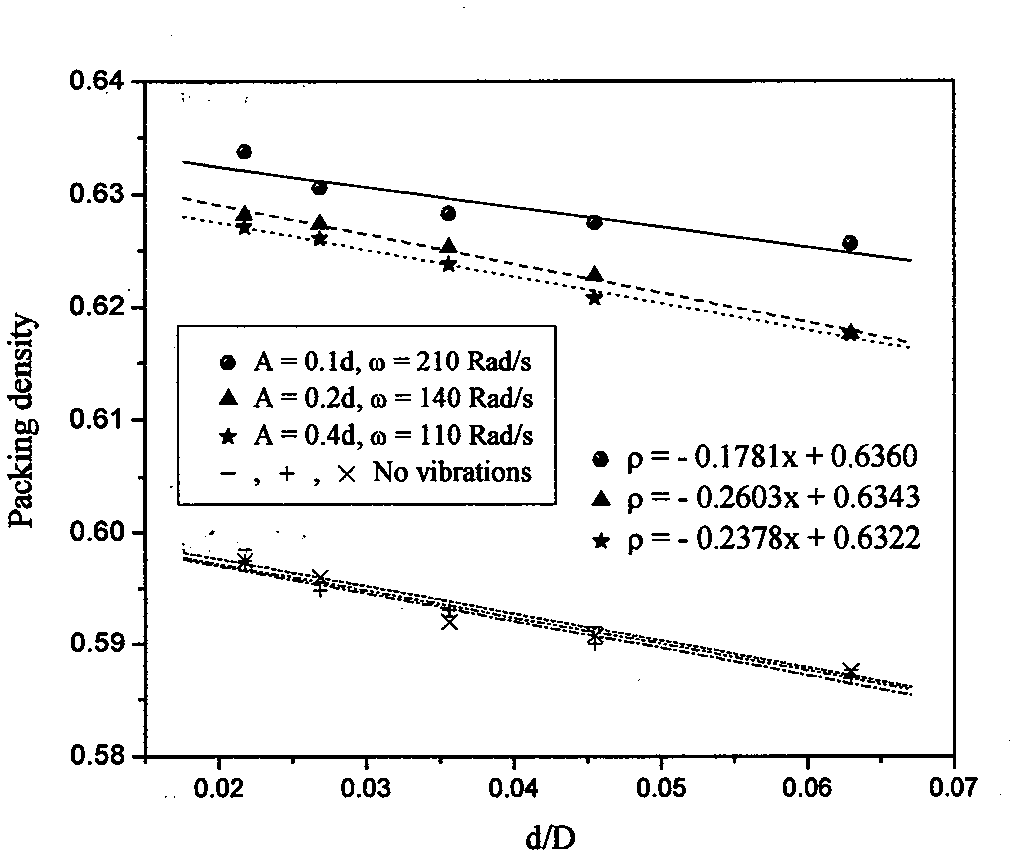

[0053] Figure 12(a) When A=0.1d, the extrapolation of particle packing density in containers of different sizes to eliminate the influence of container size, wherein: (a) bulk feeding; (b) batch feeding. The equation in Fig. 12(a) is a linear fit for each case, x=d / D (d represents the diameter of the particle and D represents the inner diameter of the container).

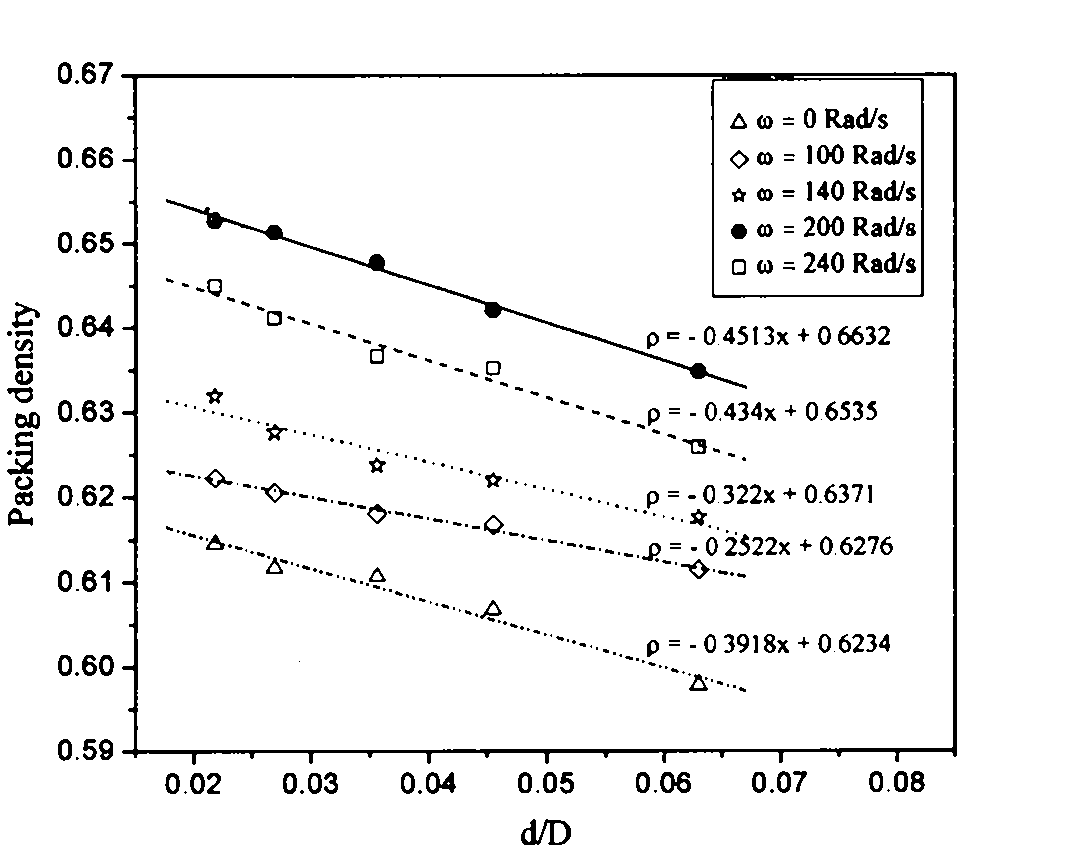

[0054] The significance of this experiment lies in: (1) By using the 1D vibration function in the invented 3D vibration equipment, the transformation of particles from random loose packing to random close packing can be realized from physical experiments, that is, the maximum random close packing structure (packing density It is about 0.64), which is of great significance for the study of the formation mechanism of the amorphous structure or amorphous structure of the material through the accumulation of hard spheres; (2) by changing the way of feeding and selecting appropriate vibration parameters, the invented eq...

example 2

[0057] Figure 13 Shown is the packing density of particles in the infinite container corresponding to different feeding batches under the 3D vibration condition of A=0.4d, ω=55Rad / s, where: (◆), feeding batch N B = 1 layer / batch; (▲), N B = 2 layers / batch; (●), N B = 3 layers / batch. Figure 13 The equations in are linear fits to each case, the inner insets represent N B = 1 layer / batch, the ordered structure obtained after removing the surface layers of particles.

[0058] In addition to obtaining the densest packing, we also studied its formation mechanism. The study found that the layer of colored particles added in the 3D vibration packing process did not undergo large density at other positions during the densification process except near the container wall. This indicates that during the vibrational accumulation process, once the ordered structure is formed, it will act as a template for the subsequent addition of particles to perform overall motion, which has been...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com