Composite precipitation tank with function of sludge carbon source transformation

A technology of composite sedimentation and sludge carbon, applied in the field of composite sedimentation tanks, can solve the problems of staying in the research and small test stage, and there is no report on the development and development of complete sets of equipment, so as to improve the efficiency of sludge hydrolysis, reduce investment costs, and reduce land use area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiment of the present invention is described in detail below in conjunction with accompanying drawing: present embodiment implements under the premise of technical scheme of the present invention, has provided detailed mode and work process, but protection scope of the present invention is not limited to following embodiment .

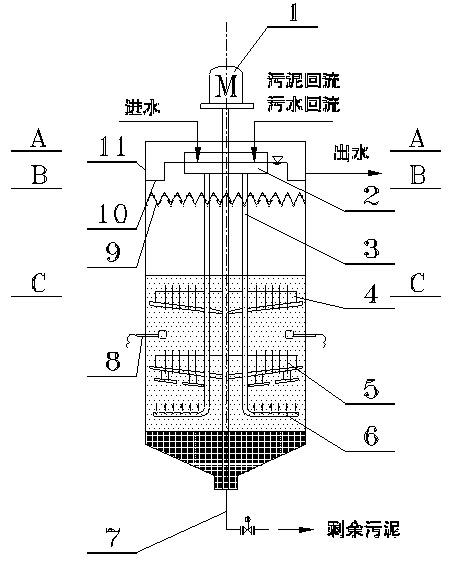

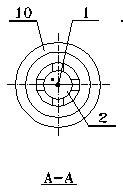

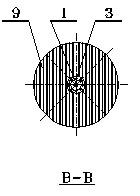

[0038] Such as figure 1 As shown, the composite sedimentation tank with the conversion function of sludge carbon source mainly includes: 1. Central frequency conversion transmission device; 2. Sludge water mixer; 3. Diversion pipe; Crushing device; 6. Slurry separator; 7. Sludge discharge device; 8. Ultrasonic generator; 9. Solid-liquid separator; 10. Rectification outlet weir. The whole equipment is divided into five parts according to different functions: 1. Carbon source conversion area - sludge is decomposed and converted into high-quality carbon source in this area; 2. Anaerobic / anoxic area - nitrate-containing sewage utilizes carbon s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com