Sludge treatment method

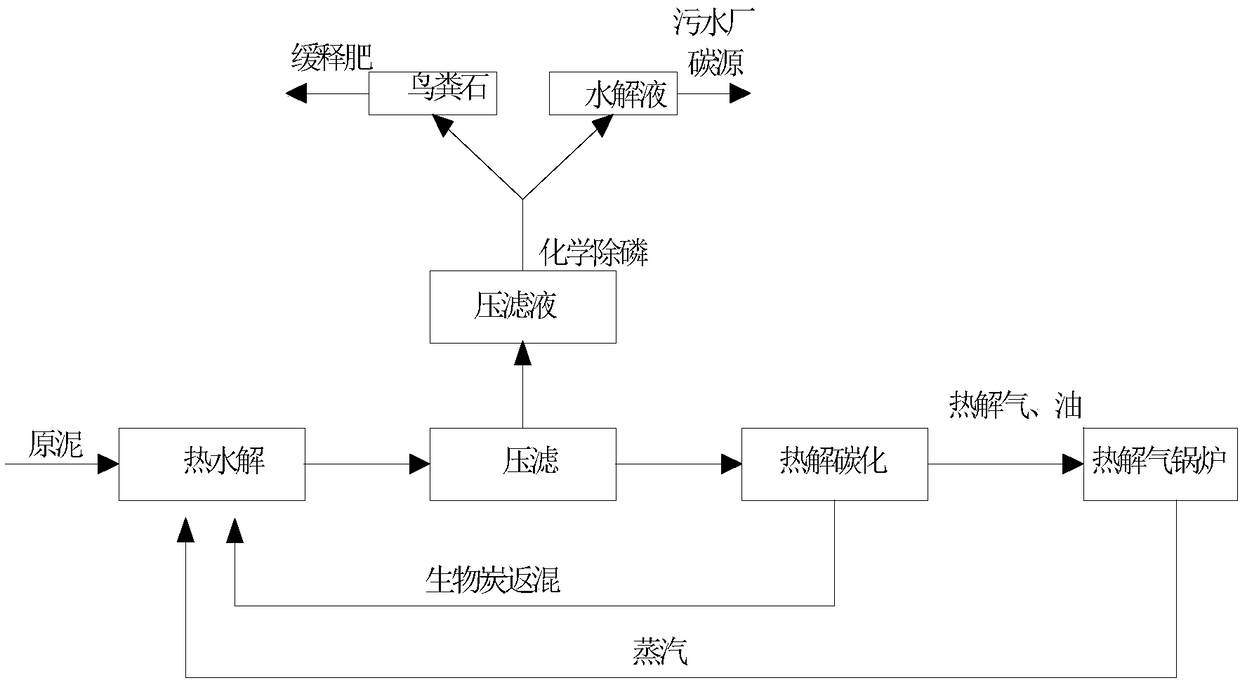

A sludge treatment and sludge technology, which is applied in the fields of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Dewatering difficulties and other problems, to achieve the effect of improving thermal hydrolysis efficiency, improving sludge hydrolysis efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Inject the sludge with a water content of 85%-95% into the reactor through the rotor pump, close the feed port of the reactor and feed 0.8Mpa saturated steam into the reactor, and stop injecting steam when the temperature of the slurry reaches 160°C. Relieve the pressure of the reactor to 0.2-0.4Mpa, and keep it for 15-30 minutes to obtain the sludge after thermal hydrolysis;

[0032] The obtained mud that has not been completely cooled after thermal hydrolysis is quickly transported to a diaphragm filter press by a screw pump for mechanical press filtration and dehydration. The feed pressure is 0.1Mpa, the pressing pressure is 3Mpa, and the pressing time is 90min to obtain mud cake and filtrate , add magnesium chloride in the filtrate, control n(P):n(Mg)=1:1.2~1.6, control pH=9~11 by the pH value acid-base automatic adjustment system, the solid that obtains is used as the slow-release fertilizer on the agriculture, obtains The liquid is used as a carbon source for nitr...

Embodiment 2

[0037]Inject the sludge with a water content of 85%-95% into the reactor through the rotor pump, close the feed port of the reactor and feed 1.5Mpa saturated steam into the reactor, and stop injecting steam after the temperature of the slurry reaches 175°C , release the pressure of the reactor to 0.2-0.4Mpa, and keep it for 15-30min, so as to obtain the sludge after thermal hydrolysis;

[0038] The obtained mud that has not been completely cooled after thermal hydrolysis is quickly transported to a diaphragm filter press by a screw pump for mechanical press filtration and dehydration. The feed pressure is 0.1Mpa, the pressing pressure is 3Mpa, and the pressing time is 90min to obtain mud cake and filtrate , add magnesium sulfate in the filtrate, control n(P):n(Mg)=1:1.2~1.6, the solid obtained by controlling pH=9~11 through the pH value acid-base automatic adjustment system is used as the slow-release fertilizer on the agriculture, obtains The liquid is used as a carbon source...

Embodiment 3

[0043] Inject the sludge with a moisture content of 85%-95% into the reactor through the rotor pump, close the feed port of the reactor and feed 2Mpa saturated steam into the reactor, and stop injecting steam after the temperature of the slurry reaches 190°C. Relieve the pressure of the reactor to 0.2-0.4Mpa and keep it for 15-30min to obtain the sludge after thermal hydrolysis;

[0044] The obtained mud that has not been completely cooled after thermal hydrolysis is quickly transported to a diaphragm filter press by a screw pump for mechanical press filtration and dehydration. The feed pressure is 0.1Mpa, the pressing pressure is 3Mpa, and the pressing time is 90min to obtain mud cake and filtrate , add magnesium sulfate in the filtrate, control n(P):n(Mg)=1:1.2~1.6, the solid obtained by controlling pH=9~11 through the pH value acid-base automatic adjustment system is used as the slow-release fertilizer on the agriculture, obtains The liquid is used as a carbon source for ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com