Refining method for ganciclovir

A ganciclovir and refining method technology, applied in the field of chemical refining, can solve the problems of long refining cycle, high energy consumption, low yield and the like, and achieve the effects of short refining cycle, low energy consumption and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

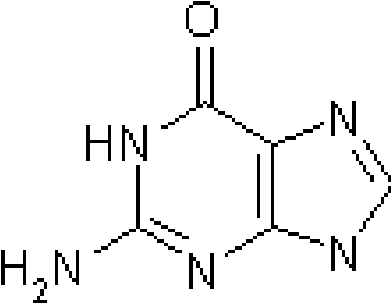

Image

Examples

Embodiment 1

[0018] A kind of guanine content is the refining method of the 20g ganciclovir crude product of 3.68%, comprises the following steps:

[0019] (1) 300ml of 20% formic acid solution is used to drop into the reaction flask, the temperature is raised to reflux, and the reflux is maintained for 0.5 hour, the solid is not completely dissolved, and 1g of gac is added, and reflux is performed for 30 minutes, filtered, the filter cake is washed with hot water, drained, and the filtrate is combined, Refrigerate to crystallize;

[0020] (2) Suction filtration gained filtrate and crystallization mixture, get crystallization product with 100ml of 5% NaOH solution, dissolve and stir at room temperature for 1 hour, add 100ml of water for dilution, then adjust the system to neutral with dilute hydrochloric acid, stir and crystallize for 2 hours Afterwards, suction filtration, the crystalline product was washed and dried to obtain 15.7 g of ganciclovir, and the impurity guanine content was re...

Embodiment 2

[0022] A kind of guanine content is the refining method of the 20g ganciclovir crude product of 1.19%, comprises the following steps:

[0023] (1) Put 300ml of 15% formic acid solution into the reaction bottle, heat up to reflux, add 1g of activated carbon after the solid is fully dissolved, reflux for 30 minutes, filter, wash the filter cake with hot water, drain, wash the filtrate and combine, put in the refrigerator to refrigerate and crystallize;

[0024] (2) Suction filtration gained filtrate and crystallization mixture, get crystallization product with 100ml of 5% NaOH solution, dissolve and stir at room temperature for 1 hour, add 100ml of water for dilution, then adjust the system to neutral with dilute hydrochloric acid, stir and crystallize for 2 hours Afterwards, suction filtration, the crystalline product was washed and dried to obtain 16.1 g of ganciclovir, and the impurity guanine content was reduced to 0.22%.

Embodiment 3

[0026] A kind of guanine content is the refining method of the 20g ganciclovir crude product of 1.19%, comprises the following steps:

[0027] (1) Put 300ml of 15% glacial acetic acid solution into the reaction bottle, heat up to reflux, add 1g of activated carbon after the solid is fully dissolved, reflux for 30 minutes, filter, wash the filter cake with hot water, drain, combine the washing filtrates, and refrigerate to crystallize ;

[0028] (2) Suction filtration gained filtrate and crystallization mixture, get crystallization product with 100ml of 5% NaOH solution, dissolve and stir at room temperature for 1 hour, add 100ml of water for dilution, then adjust the system to neutral with dilute hydrochloric acid, stir and crystallize for 2 hours Afterwards, suction filtration, the crystalline product was washed and dried to obtain 16.3 g of ganciclovir, and the impurity guanine content was reduced to 0.42%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com