Antifog paddy rice sprout cultivation film

A technology for rice seedling raising and anti-fog, applied in the direction of plant protection cover, etc., can solve the problems of poor anti-fog effect, rotten seedlings, etc., and achieve the effects of increasing light transmittance, raising seedling temperature, and excellent and lasting hydrophilic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

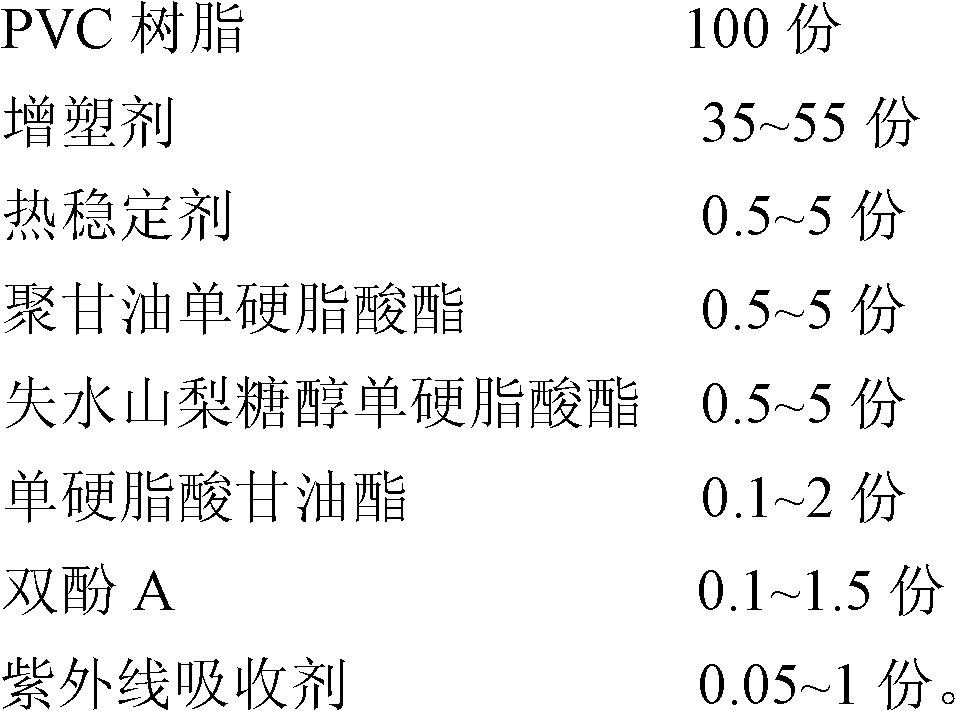

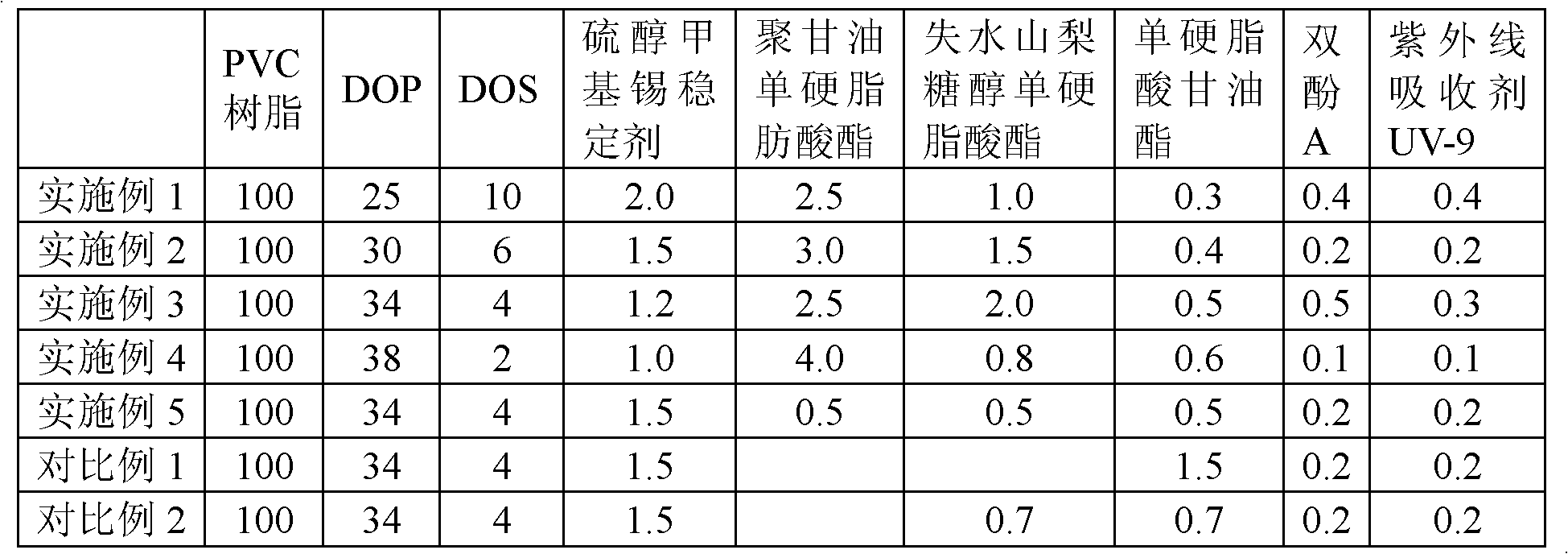

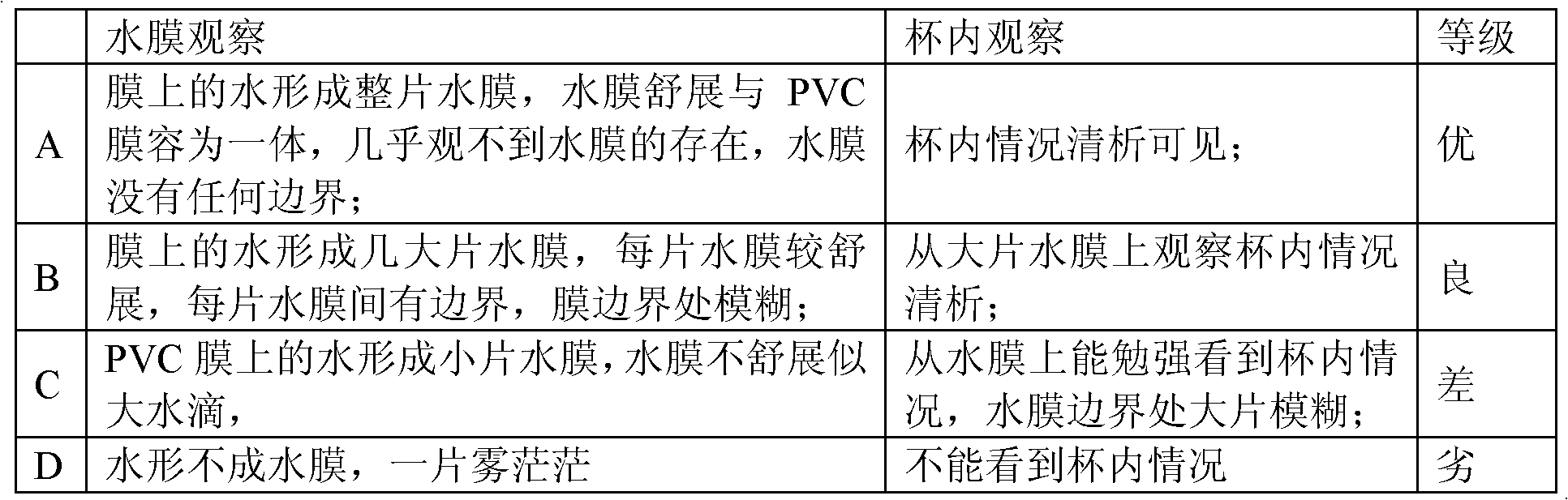

Method used

Image

Examples

Embodiment Construction

[0027] film preparation

[0028] (1) Put each raw material into a high-speed mixer according to the ratio shown in Table 1, knead until the temperature reaches 105°C and discharge, put it into a low-speed cooling mixer and cool to normal temperature to obtain a mixed powder;

[0029] (2) Put the mixed powder into the hopper of the extruder, the hopper is equipped with a forced feeding device to prevent the powder from bridging, and the hopper seat strengthens the water cooling device to prevent the powder from being heated and stuck;

[0030] (3) Extrusion blow molding adopts Φ120 extruder, the screw length-to-diameter ratio is 1:28, the screw type is BM type (separate type), and the temperature control is (five-zone heating of the fuselage): 140°C in the first zone and 150 in the second zone ℃, 160℃ in the third zone, 170℃ in the fourth zone, 175℃ in the fifth zone, 165℃ in the flange, and 180℃ in the machine head;

[0031] (4) Winding to obtain a finished film with a thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com