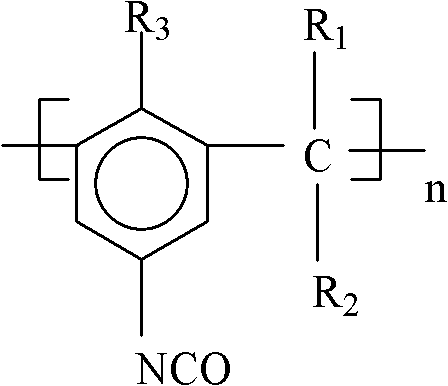

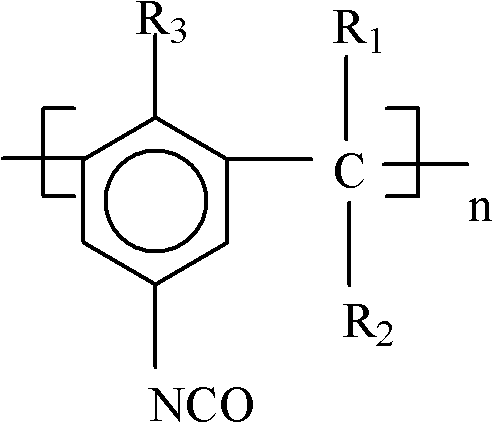

Compatible polyamide-polyphenyl ether composition and preparation method thereof

A technology of polyphenylene ether and polyamide, which is applied in the field of compatibilized polyamide-polyphenylene ether composition and its preparation, can solve the problems of low reactivity of functional groups, increase energy consumption, affect equipment capacity utilization, etc., and achieve high Reactivity, excellent overall performance, and enhanced interface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and comparative example 1~2

[0040] The preparation method of the compatibilized polyamide polyphenylene ether composition that following embodiment relates to, comprises the following steps:

[0041] (1) take raw materials according to parts by weight in Table 1;

[0042] (2) The raw materials are mixed in a high-speed mixer;

[0043] (3) Put the above-mentioned mixed raw materials into a twin-screw extruder, extrude and granulate through melting reaction. Among them, the twin-screw extruder has a total of 10 temperature control zones from the feeding port to the die, and the temperatures from zone 1 to zone 10 are set as 180°C, 220°C, 240°C, 260°C, 270°C, 270°C, 280°C, 280°C, 290°C, 290°C, the die temperature is set to 290°C. The aspect ratio of the screw is 58, and the screw speed is 500 rpm. The extraction equipment is installed in two places, respectively in the fifth area and the eighth area, and the vacuum degree is 0.06MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com