Large-scale fly larvae breeding equipment and application method thereof

An equipment and fly maggot technology, applied in animal husbandry and other directions, can solve the problems of young maggots just hatching, flies escape, and maggot manure separation takes up a lot of labor, so as to reduce breeding labor, improve breeding efficiency, and reduce heating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make it easy to understand the technical means, creative features, work flow, and use methods of the present invention to achieve the purpose and effect, the present invention will be further explained below in conjunction with specific drawings.

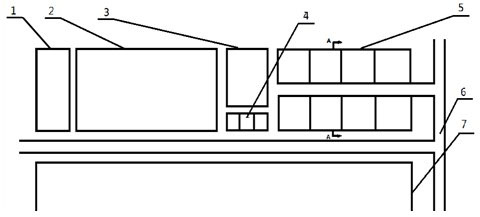

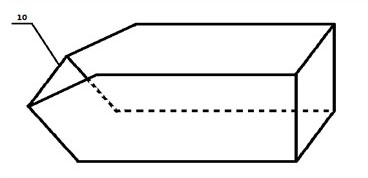

[0031] Such as figure 1 As shown, choose a large-scale breeding farm that is convenient for collecting livestock and poultry manure, build a boiler house 1, a breeding house for breeding flies and a breeding house for juvenile maggots, 2, an operating platform 3, a fermentation tank 4, a sunning tank 5, and a passage 6.

[0032] Boiler room 1: Its size is 4m×7m, and the height is 3m. It adopts a steam-liquid dual-purpose atmospheric pressure boiler and uses coal as fuel. When the temperature in the breeding house and young maggot breeding house drops below 20℃ Heat the room.

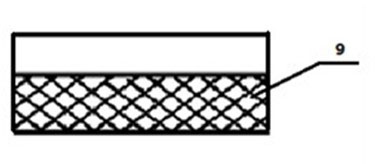

[0033] Breeding house for breeding flies: its size is 11m×7m, and the height is 3m. It is a steel frame. The walls and roof are built with new th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com